Control method of thick plate rolling warping and bending

A control method, the technology of warped buckle head, applied in the direction of contour control, metal rolling, etc., can solve the problem of warped buckle head summary and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

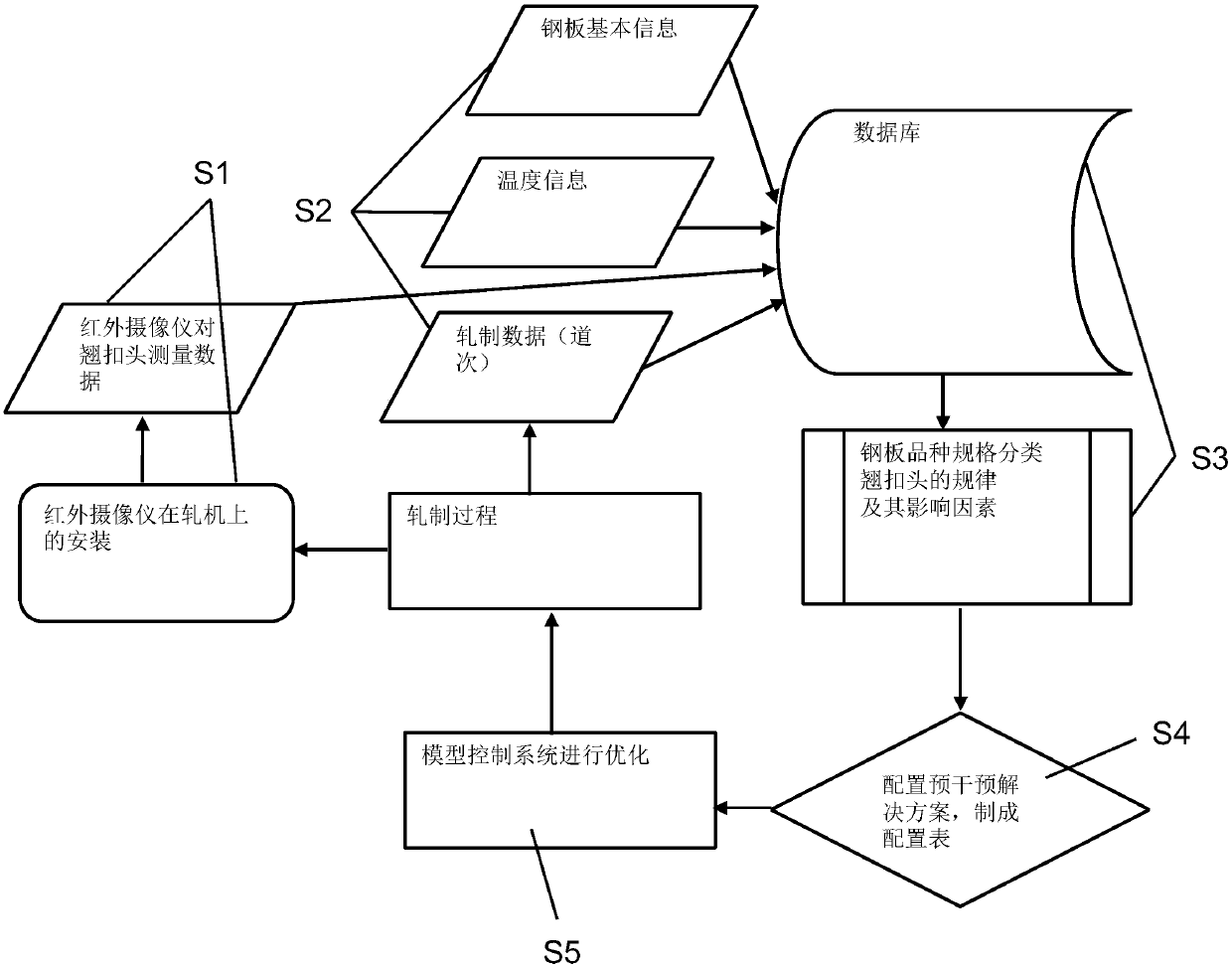

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] Please combine Figure 2 to Figure 6 As shown, the present invention provides a method for controlling buckling head in thick plate rolling, comprising the following steps:

[0044] S1. Collection and uploading of measurement data of rolled buckle head, details are as follows:

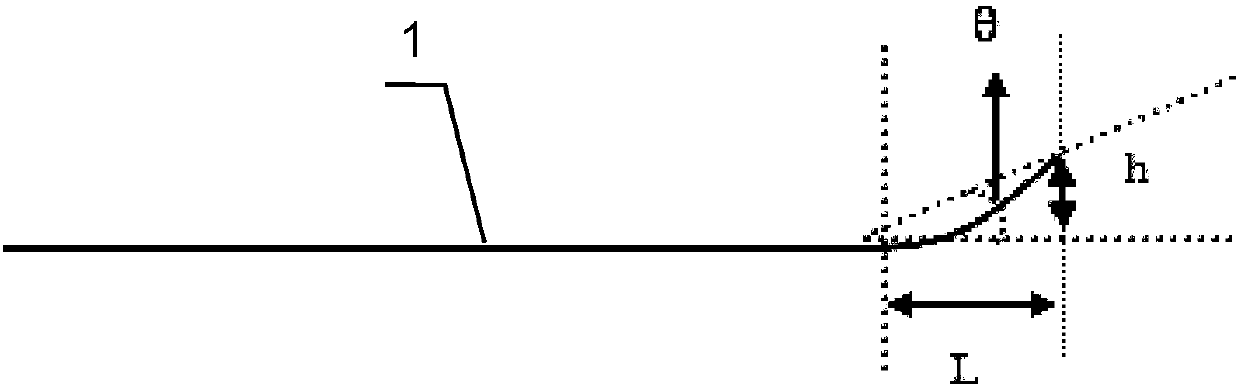

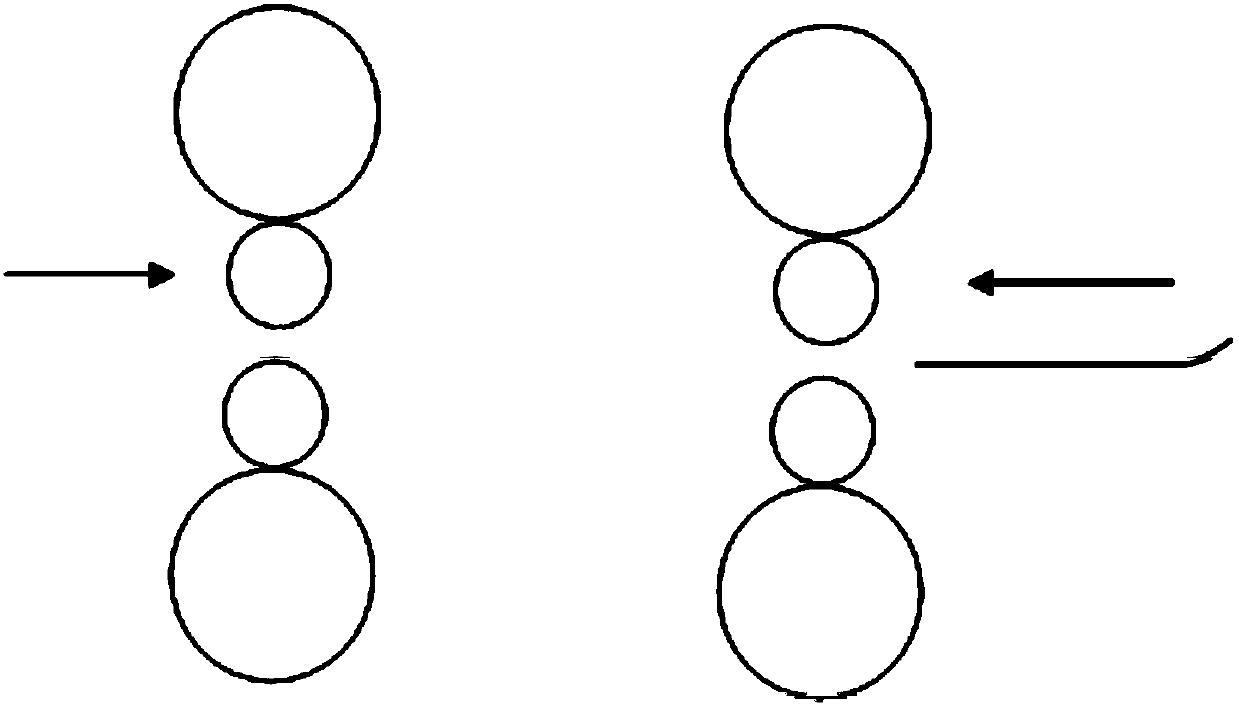

[0045] The infrared camera is used as the measuring tool for the rolled buckle head. Because the rolling of the thick plate mill is reversible rolling, the head of the rolled piece will pass the infrared camera twice in the first pass and the last pass of non-rolling. That is, the infrared camera as the measuring device takes pictures of the head of the steel plate rolled out of the rolling mill and the tail of the steel plate entering the rolling mill ( image 3 The direction of the middle arrow is the shooting direction of the infr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com