Cast-in-place box girder bottom web steel bar segmented prefabricated binding mold and binding method

A bottom web and segmented technology, which is applied in bridges, bridge materials, bridge construction, etc., can solve problems such as low efficiency and nesting phenomenon, achieve accurate pre-bundling of steel bars, controllable spacing errors, and reduce binding occupancy the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

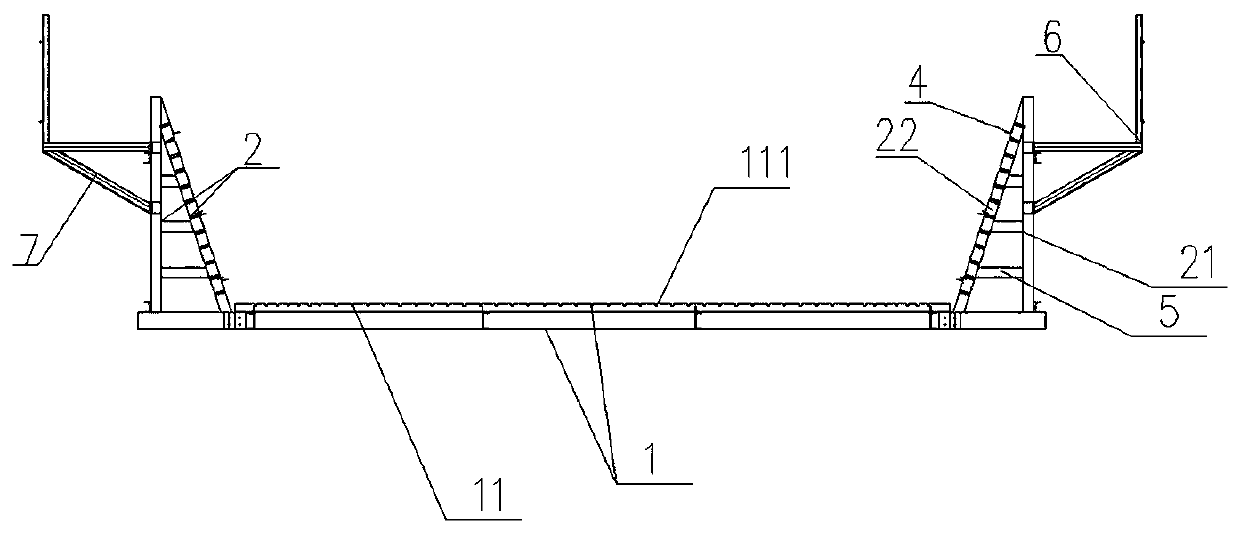

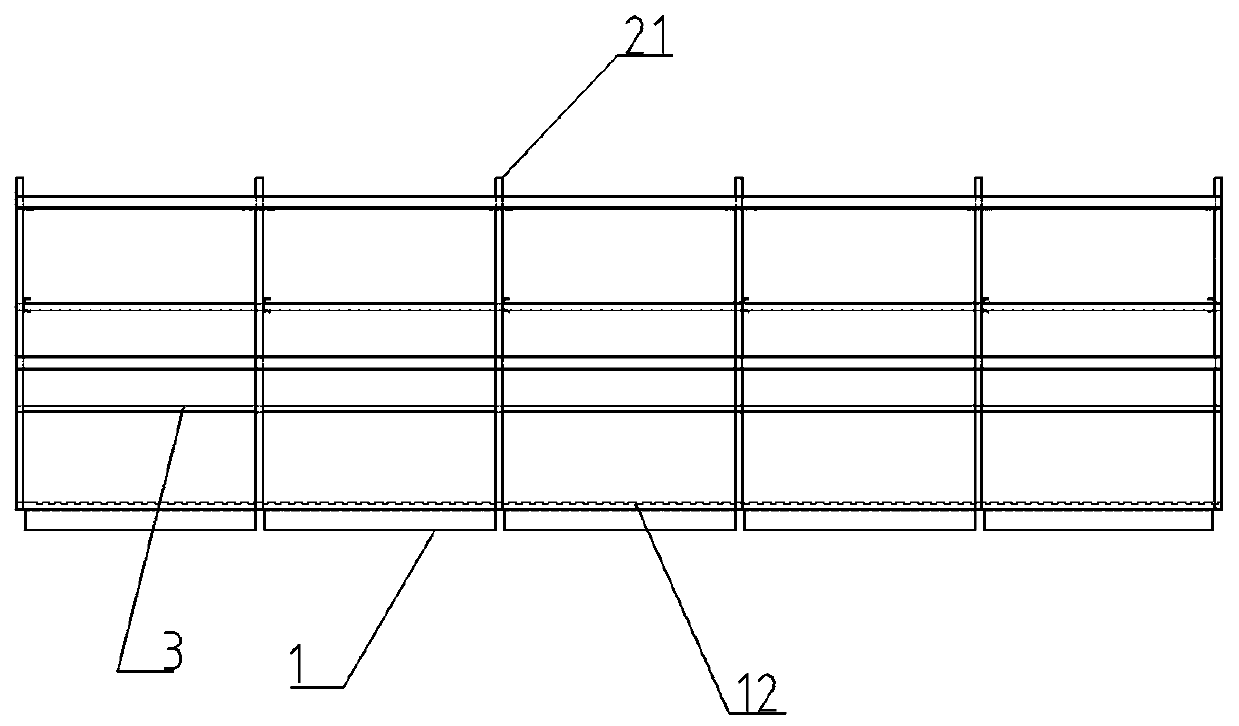

[0023] A segmental prefabricated binding method for the bottom web reinforcement of a cast-in-place box girder, comprising the following steps:

[0024] 1) According to the span of the box girder and the size of the bottom web reinforcement, the spacing of the reinforcement, and the model, the prefabricated binding molds for the bottom web reinforcement of the box girder are made in sections;

[0025] 2) Set groove positioning at the corresponding position on the mold;

[0026] 3) Bind the steel bars of the bottom web of the box girder to the mold in sections;

[0027] 4) Lift the reinforcement of the bottom web into the mold by the steel cage hoist and the gantry crane, then hoist the prefabricated inner membrane, and finally bind and form the bridge deck reinforcement on site.

[0028] A cast-in-place box girder bottom web reinforcing bar is prefabricated in sections, including a base plate support 1 and a side plate support 2, the base plate support 1 and the side plate su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com