Post-tensioned method prestressed concrete box beam whole opening prefabricated construction method

A concrete box girder and construction method technology, applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of lack of mature technology, high technical requirements, and difficult engineering, and achieve good outline size and strong operability , Lifting and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

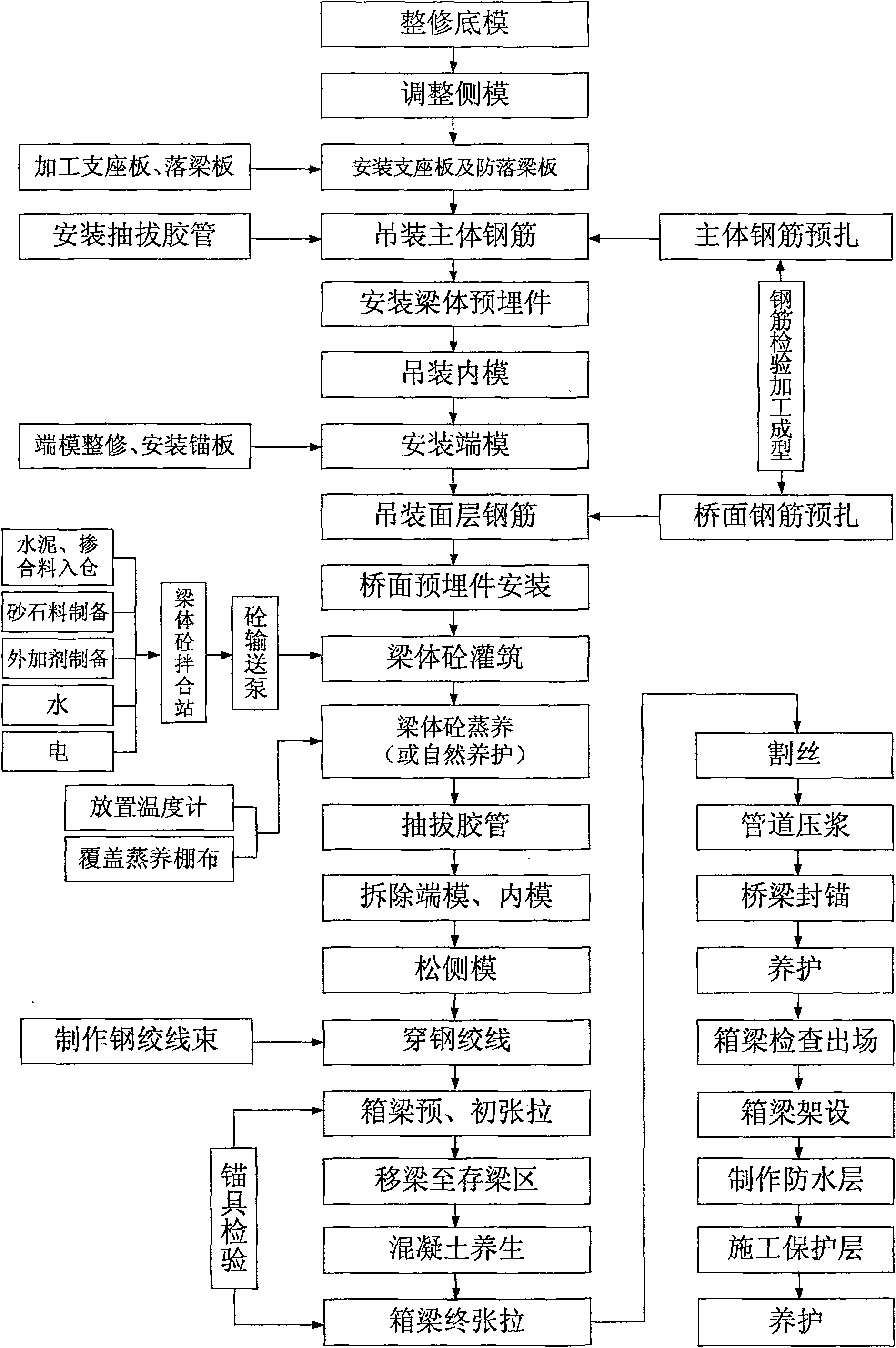

[0047] The technological process of the post-tensioned prestressed concrete box girder whole hole prefabrication construction method in this embodiment is as follows figure 1 As shown, its main steps include:

[0048] (1) Install templates, steel bars and embedded parts, etc.:

[0049] The steps mainly include: repairing the bottom mold, adjusting the side mold, installing the support plate and the anti-drop beam plate, installing the drawing hose, hoisting the main steel bar, installing the embedded parts of the beam body, hoisting the inner mold, installing the end mold, Hoisting surface reinforcement, bridge deck embedded parts installation, etc.

[0050] In this step:

[0051] Both the main reinforcement and the bridge deck reinforcement adopt centralized pre-tie-up and overall hoisting technology, that is, the processing of the box girder reinforcement (including the main reinforcement and bridge deck reinforcement) is completed in the reinforcement workshop, and then b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com