A method for directly supplementing carbon dioxide from coke oven gas to produce synthetic natural gas

A technology for supplementing carbon dioxide and synthesizing natural gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve problems such as difficult temperature control, increased investment cost, and complicated process flow, and achieve the goal of improving economic efficiency, good economic efficiency, and increasing production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

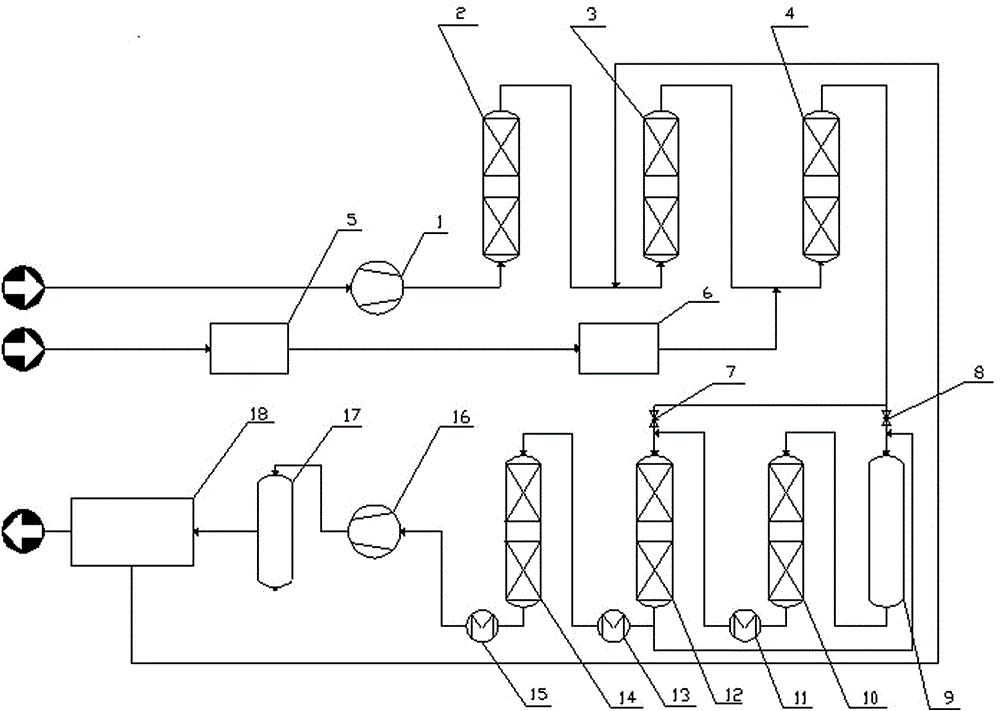

[0023] The purpose, principle and features of the present invention will be specifically described in the best embodiments below in conjunction with the accompanying drawings.

[0024] The purpose of the present invention is to make full use of the hydrogen in the coke oven gas, and take the coke oven gas as the raw material gas by supplementing a certain amount of CO 2The gas is formulated into a synthesis gas with a suitable ratio of carbon to hydrogen, and then SNG is produced through methanation and membrane separation, while by-product steam.

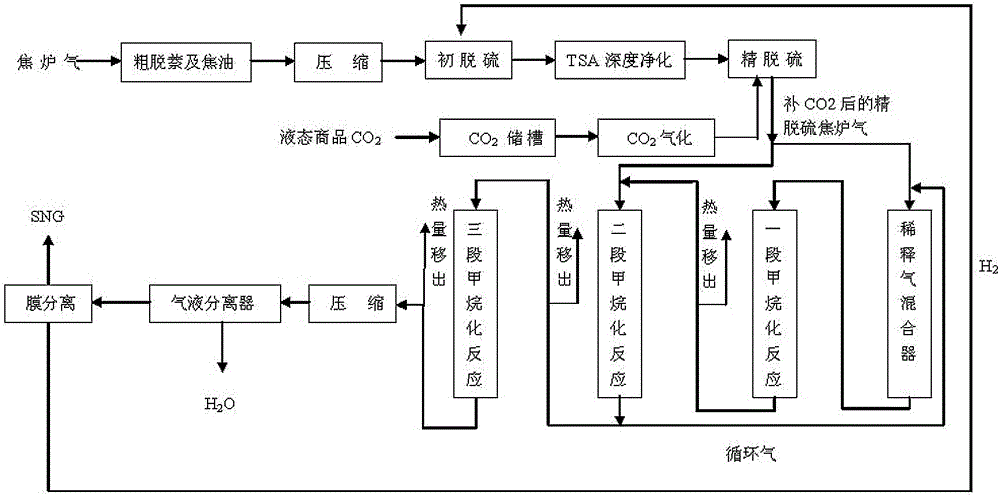

[0025] figure 1 It is a schematic diagram of the process flow of the method of the present invention. Depend on figure 1 It can be seen that the main process of the present invention comprises coke oven gas compression process, coke oven gas purification process, methanation process and CO 2 Gasification process.

[0026] (1) Coke oven gas compression process.

[0027] The raw material gas used in the method of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com