Special bearing and bearing composite construction for X ray tube

A combined structure and bearing technology, applied in the direction of bearing components, shafts and bearings, X-ray tube electrodes, etc., can solve problems such as dispersion, and achieve the effects of increased life, optimized structure, and reduced vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

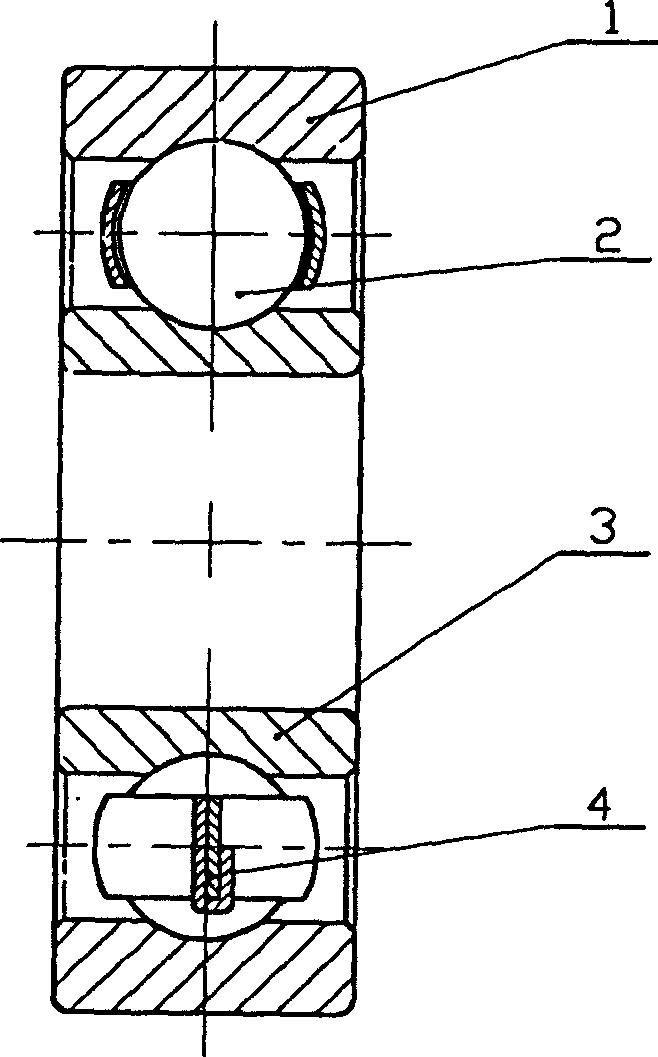

[0016] In the present invention, the special bearing for the X-ray tube of the X-ray machine adopts the outer ring (1) and the inner ring (3) of the bearing to be made of high-speed steel; After treatment, a layer of MOS2 dense film lubricating layer is formed on the surface by sputtering spraying method; the steel ball (2) is made of high-speed steel, and its surface is silver-plated by ion method to form a layer with high bonding strength with the basic material and does not A uniform coating greater than 0.001mm; the cage (4) is stamped and formed by stainless steel material 1Cr18Ni9, and a layer of lubricating silver layer no greater than 0.01mm is formed on the surface by electroplating; through the above measures, the special bearing is suitable for high-speed, high-temperature, and precision applications Combined lubrication reliability.

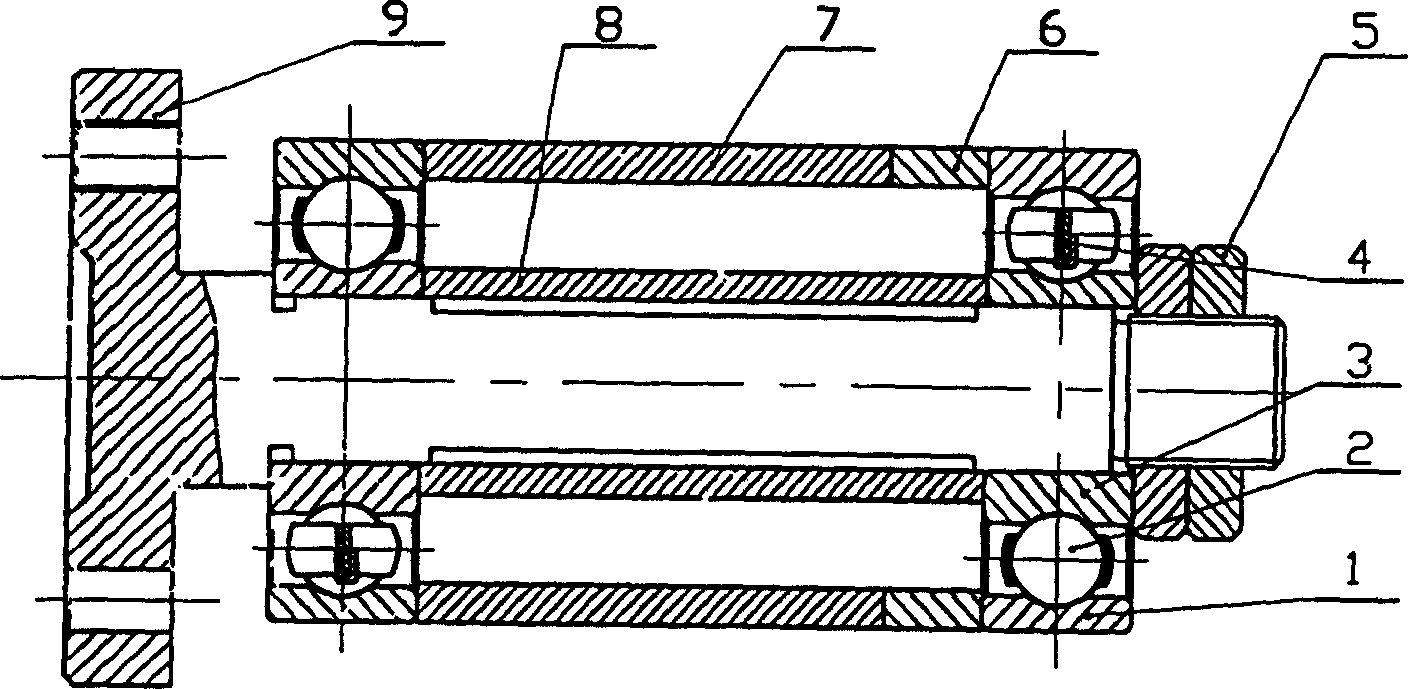

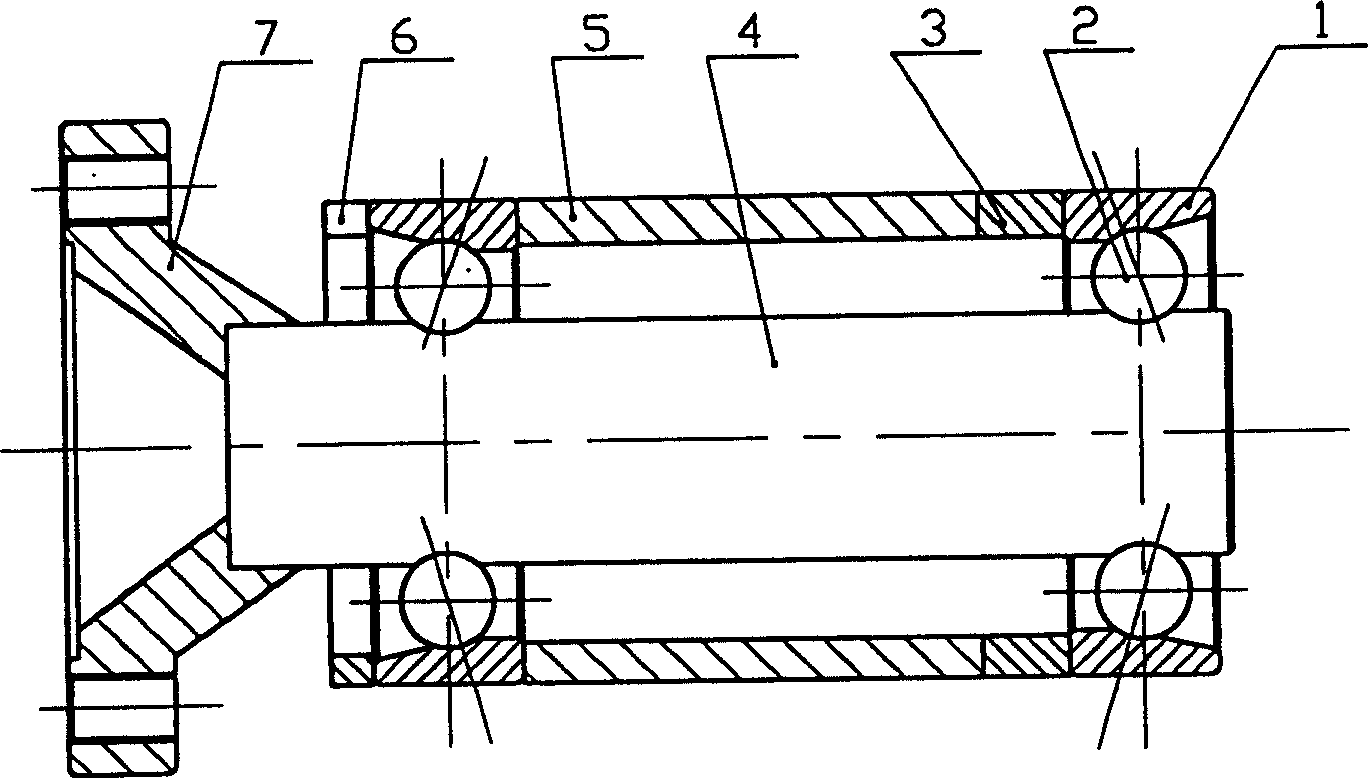

[0017] The bearing combination structure assembly is composed of two sets of special bearings, and the coaxiality of the two sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com