Titanium-calcium plate and preparation method thereof

A technology of calcium titanium and titanium dioxide is applied in the field of calcium titanium plate and its preparation, which can solve the problems of insufficient strength, low fracture load, and insufficient whiteness, and achieve the effects of improving compactness, stable product yield and stable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] According to a second aspect of the present invention, there is provided a method for preparing a titanium-calcium plate, comprising the following steps:

[0071] First mix β gypsum powder, titanium dioxide, optional antibacterial agent, optional adsorbent and optional negative oxygen ion release agent, then age, homogenize, and then fluidize into the silo, and then the ingredients enter the molding process, The formed product is exposed to sunlight to obtain a titanium-calcium plate.

[0072] Preferably, on the basis of the preparation method provided by the present invention, the titanium dioxide is nanoscale titanium dioxide.

[0073] Preferably, based on the preparation method provided by the present invention, the addition amount of titanium dioxide is 10-15 wt%.

[0074] Typical but non-limiting percentages of titanium dioxide added are, for example, 10%, 11%, 12%, 13%, 14%, and 15%.

[0075] Preferably, the mixing process is performed using a high-speed separat...

Embodiment 1

[0092] A preparation method of titanium-calcium plate, comprising the following steps:

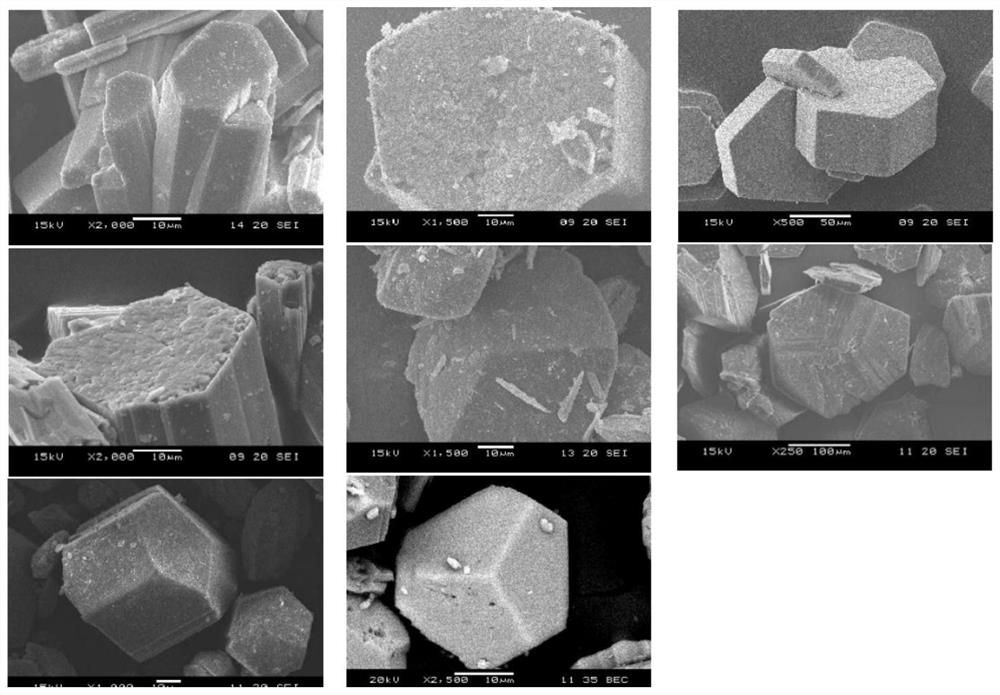

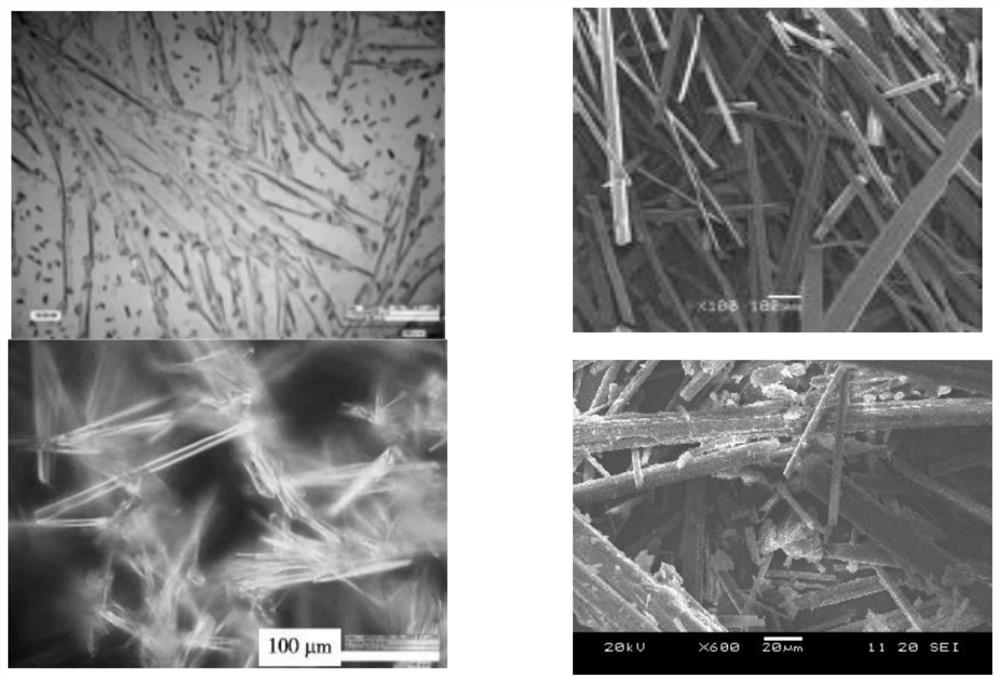

[0093] Add 100kg of nanoscale titanium dioxide, 10kg of antibacterial agent-penicillin powder, 10kg of adsorbent-formaldehyde adsorbent and 10kg of negative oxygen ion release agent-negative oxygen ion powder into 870kg of β gypsum powder, and mix them thoroughly through a high-speed separator. form titanium-calcium composites. Subsequently, the composite material is poured into an aging homogenization bin equipped with an ultraviolet generator, and after aging and homogenizing for 8 hours, it is fluidized into the bin. Then carry out batching, according to the ratio of powder to water 1kg:0.6kg, that is, add 0.6kg of water to 1kg of dry powder, stir it into a slurry of standard consistency, and enter the molding process. Finally, the molded product was exposed to the sun for 3 days to obtain a titanium-calcium plate, and its crystal morphology is as shown in the attached figure 1 shown....

Embodiment 2

[0096] The difference between this example and Example 1 is that the amount of nano-scale titanium dioxide added is different, and the amount of added titanium dioxide in this example is 13 wt%.

[0097] After testing, the 2-hour flexural strength of the titanium-calcium plate prepared by the method of this example is 4.3 MPa, the Mohs hardness is 7.3, and the whiteness is 89 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com