Lubricating oil processing system and lubricating oil

A processing system and lubricating oil technology, which is applied in the field of lubricating oil, can solve the problems of synchronously changing the mixing speed of adding speed, low mixing efficiency, and poor mixing effect of lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

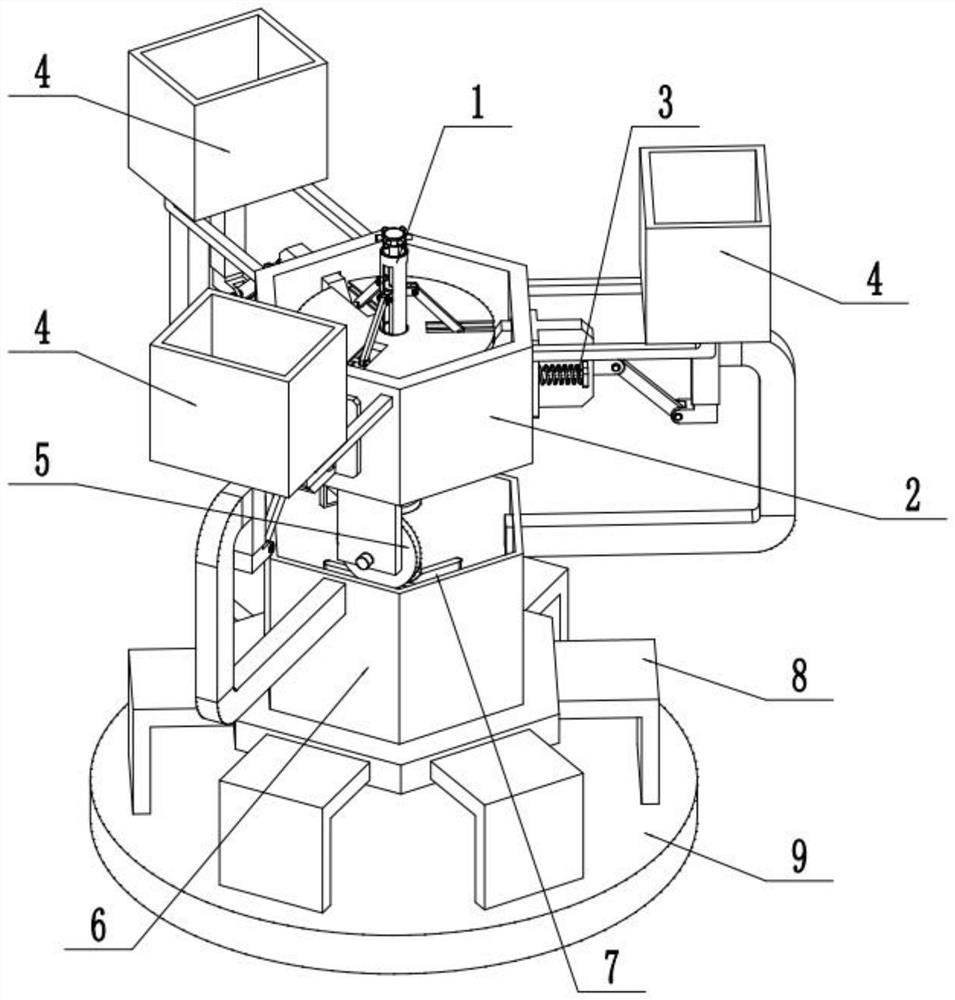

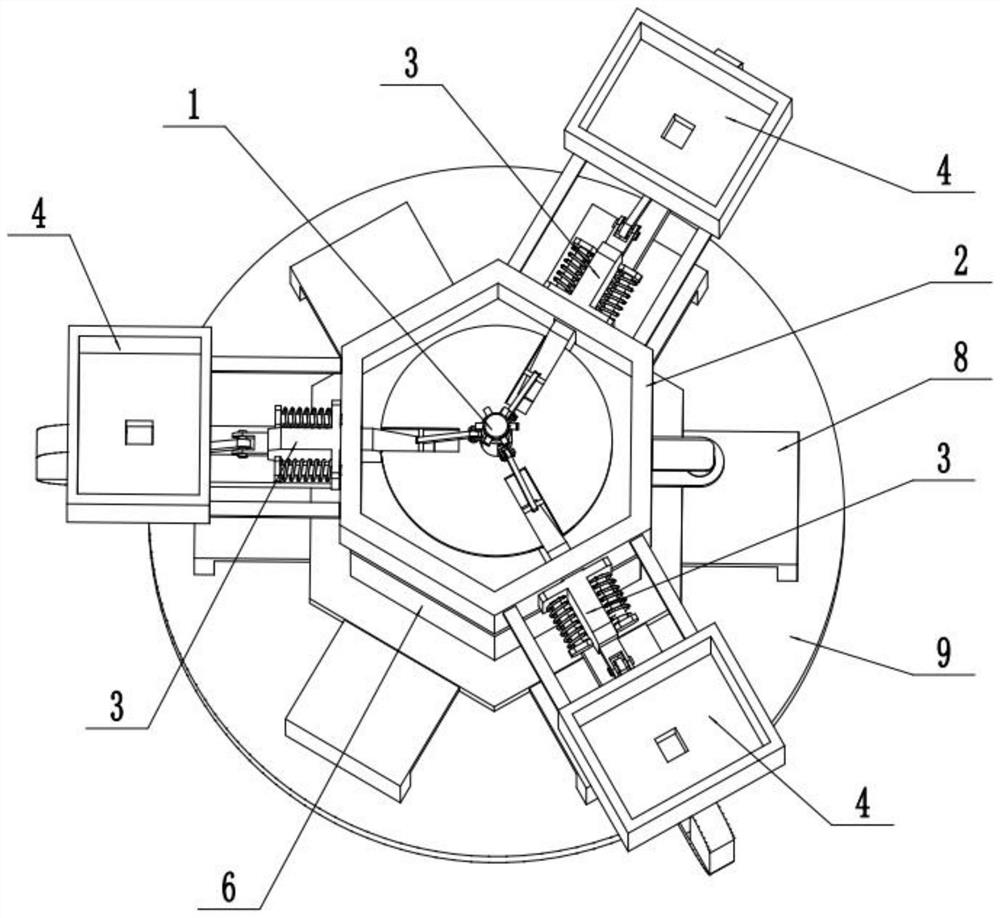

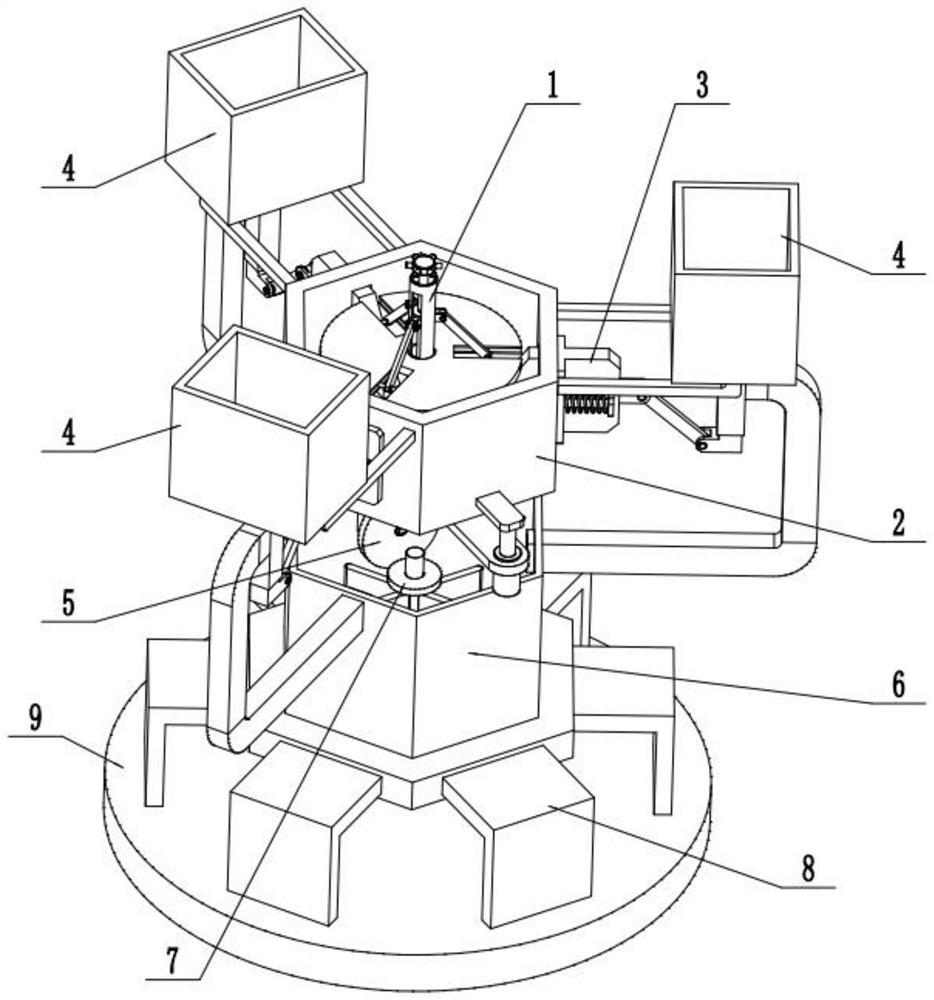

[0031] Such as Figure 1-13 As shown, a lubricating oil processing system includes a central controller 1, a hexagonal box 2, a feed controller 3, a raw material box 4, a drive 5, a mixing box 6, a mixer 7, a support frame 8 and a base 9, The upper end of the central controller 1 is driven to connect the inner ends of a plurality of feed controllers 3, and the middle parts of the plurality of feed controllers 3 are uniformly surrounded and connected to the side of the hexagonal box 2, and the inner ends of the plurality of feed controllers 3 The outer ends are respectively driven and connected to a raw material box 4; the upper ends of a plurality of raw material boxes 4 are respectively fixedly connected to the sides of the hexagonal box 2, and the lower ends of the plurality of raw material boxes 4 are respectively fixedly connected to the side surfaces of the upper end of the mixing box 6; The center of the central controller 1 is connected to the hexagonal box 2; the lower...

specific Embodiment approach 2

[0032] Such as Figure 1-13 As shown, a plurality of vertical sliding holes 2-1 are evenly arranged on the side of the six-edged box 2; the number of the vertical sliding holes 2-1, the number of feed controllers 3 and the number of raw material boxes 4 are the same and One by one relative settings.

specific Embodiment approach 3

[0033] Such as Figure 1-13 As shown, the central controller 1 includes a pressure plate 1-1, a central shaft 1-2, a central seat plate 1-3, a servo motor 1-4, a friction transmission wheel 1-5, an electric push rod 1-6 and a horizontal seat 1-7; the pressure plate 1-1 is fixedly connected to the upper end of the central shaft 1-2, the middle part of the central shaft 1-2 is slidingly fitted and connected to the center of the bottom surface of the hexagonal box 2, and the lower end of the central shaft 1-2 is fixedly connected On the top surface of the center seat plate 1-3; the servo motor 1-4 is fixedly connected to the bottom surface of the center seat plate 1-3 through the motor seat, and the output shaft of the servo motor 1-4 is fixedly connected to the friction transmission wheel 1 -5; the friction transmission wheel 1-5 is frictionally connected to the driver 5; the fixed end of the electric push rod 1-6 is fixedly connected to the center seat plate 1-3, and the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com