Modified asphalt mixing tank structure

A technology of modified asphalt and mixing tank, applied in the field of asphalt tank, can solve the problems of gas pollution environment, unable to obtain heating effect of processing raw materials, poor mixing production effect of modified asphalt, etc., so as to avoid environmental pollution and improve mixing processing effect. , improve the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

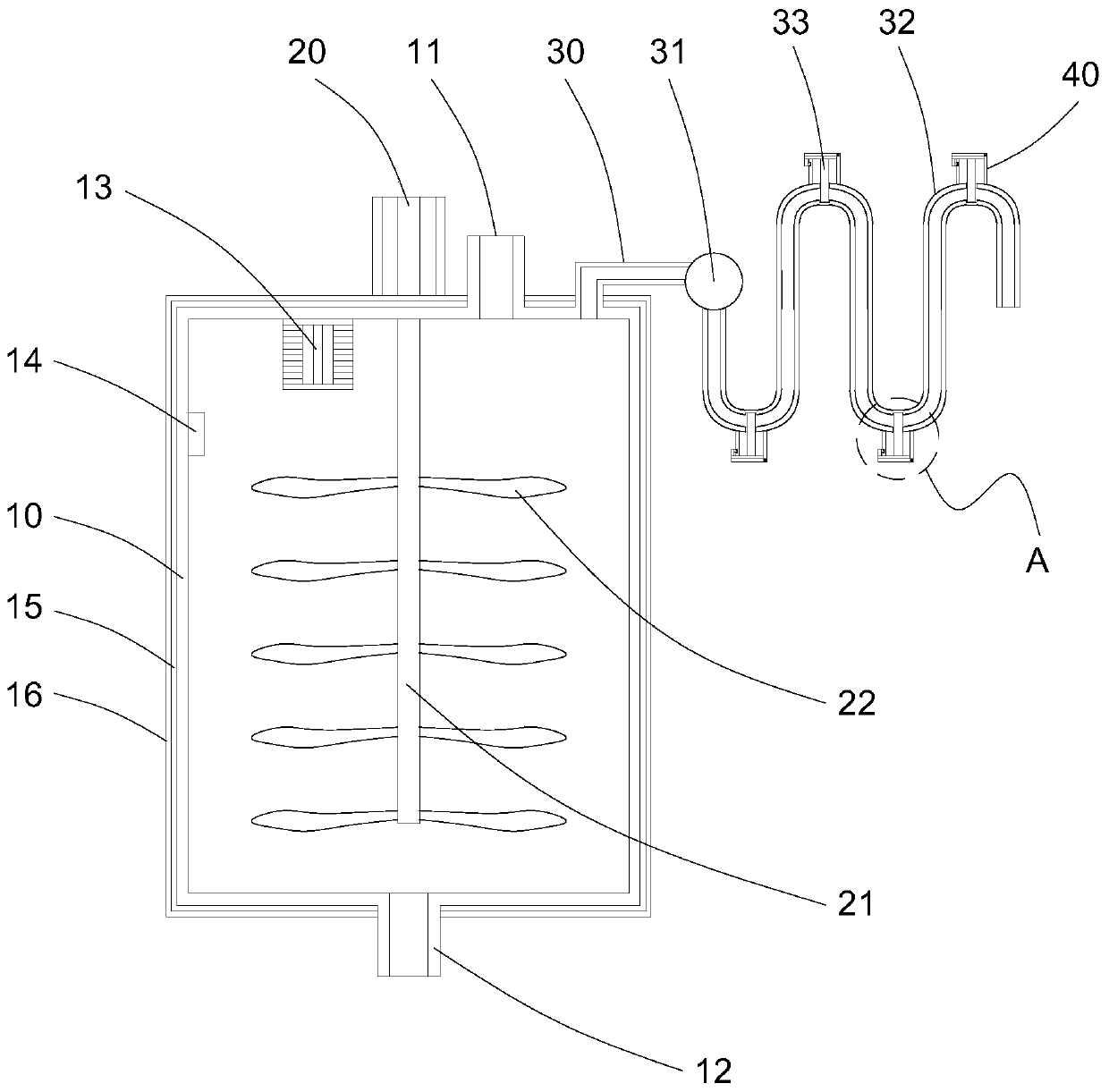

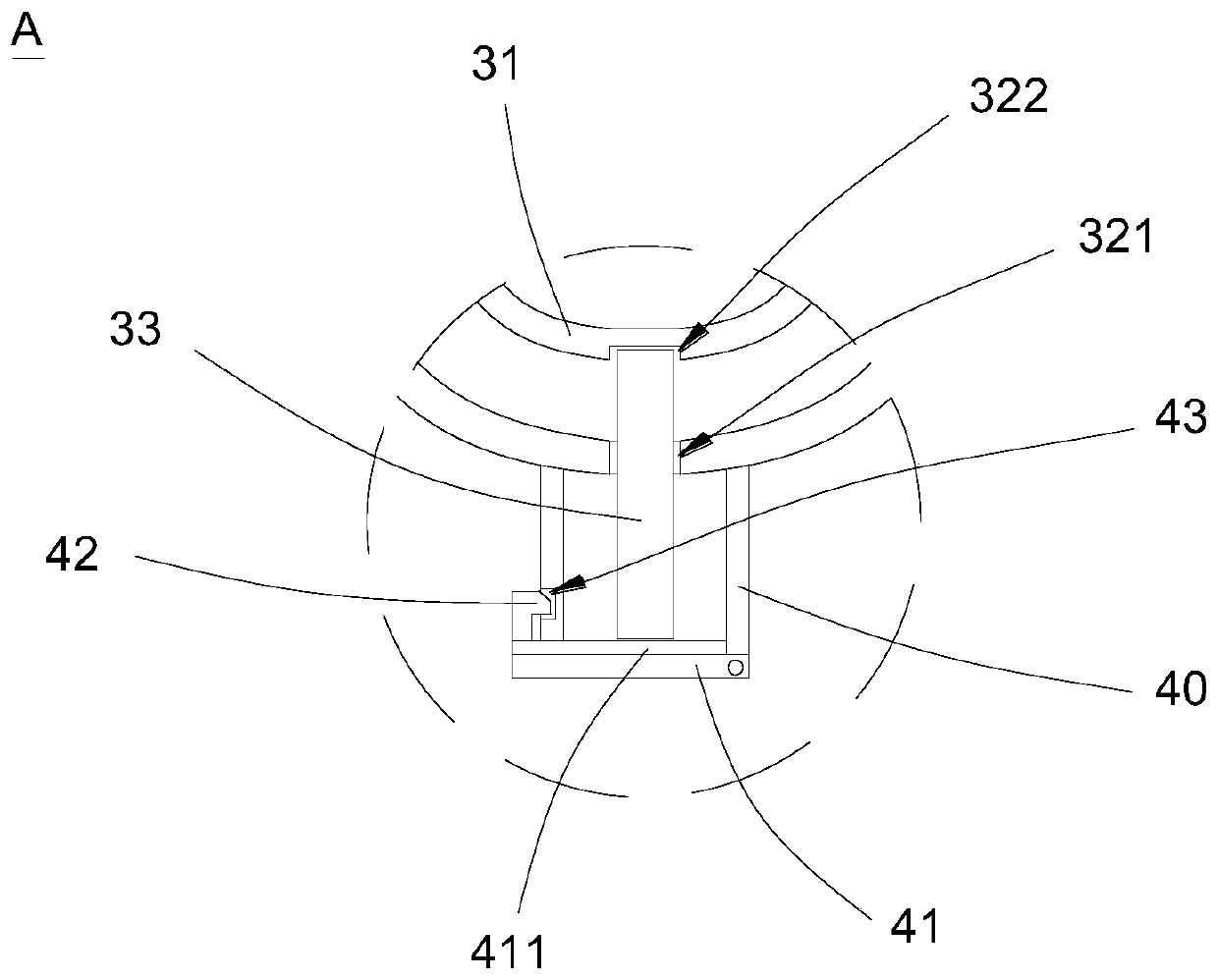

[0020] refer to figure 1 , figure 2 .

[0021] The embodiment of the present invention discloses a modified asphalt mixing tank structure, which includes a tank body 10, the upper and lower sides of the tank body 10 are respectively connected with a feed pipe 11 and a discharge pipe 12, and the feed pipe 11 is provided with a device for controlling feeding. Valve, the discharge pipe 12 is provided with a valve for controlling the discharge, and the top of the inner wall of the tank body 10 is provided with a magnetron 13 for forming microwaves. Preferably, the output end of the magnetron 13 is connected with a metal waveguide. The magnetron 13 can form microwaves to uniformly and efficiently heat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com