Shale shaker basket system

A vibrator and shale technology, applied in the field of shale vibrator screening device, can solve the problems of low cost and low operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Some implementations are described by way of example and with reference to the accompanying drawings

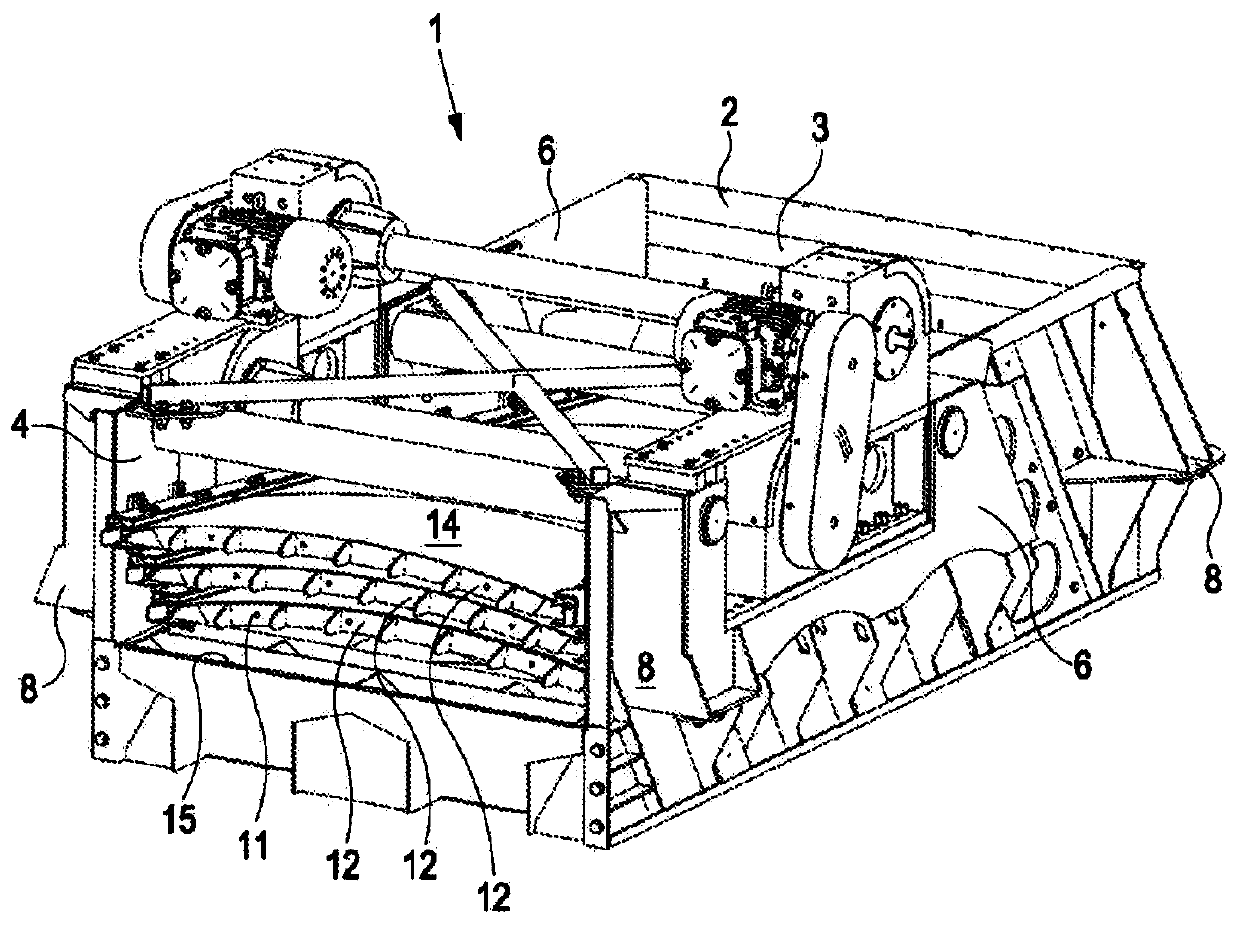

[0080] figure 1 A prior art shale shaker basket 1 of the same type as shown in WO2015 / 166282 of the same inventor as the present application is shown. The basket 1 has a feed end 2 at the rear with a fluid retaining wall 3 which is the rear end of the basket. The solids discharge end 4 at the front of the basket is separated from the feed end 2 by a side 6 . The basket has mounts 8 for shock absorption (not shown) to allow the basket 1 to float on a base (also not shown) when driven by a vibratory drive system 10 .

[0081] Visible at the front end of the basket are three closely spaced screen stacks 11 comprising a screen frame 12 and a screening surface 14 . Solids falling from the ends of the screen deck 11 can be collected and distributed through the trough means 15 as required.

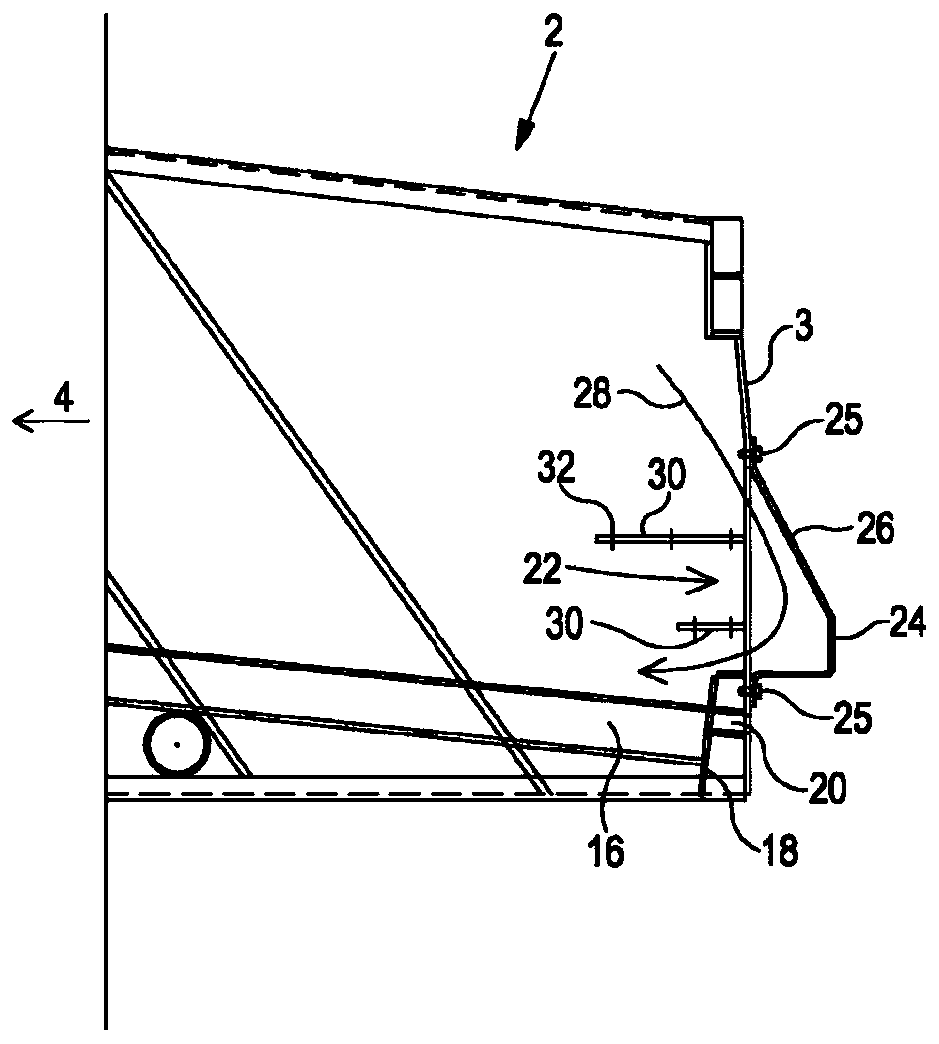

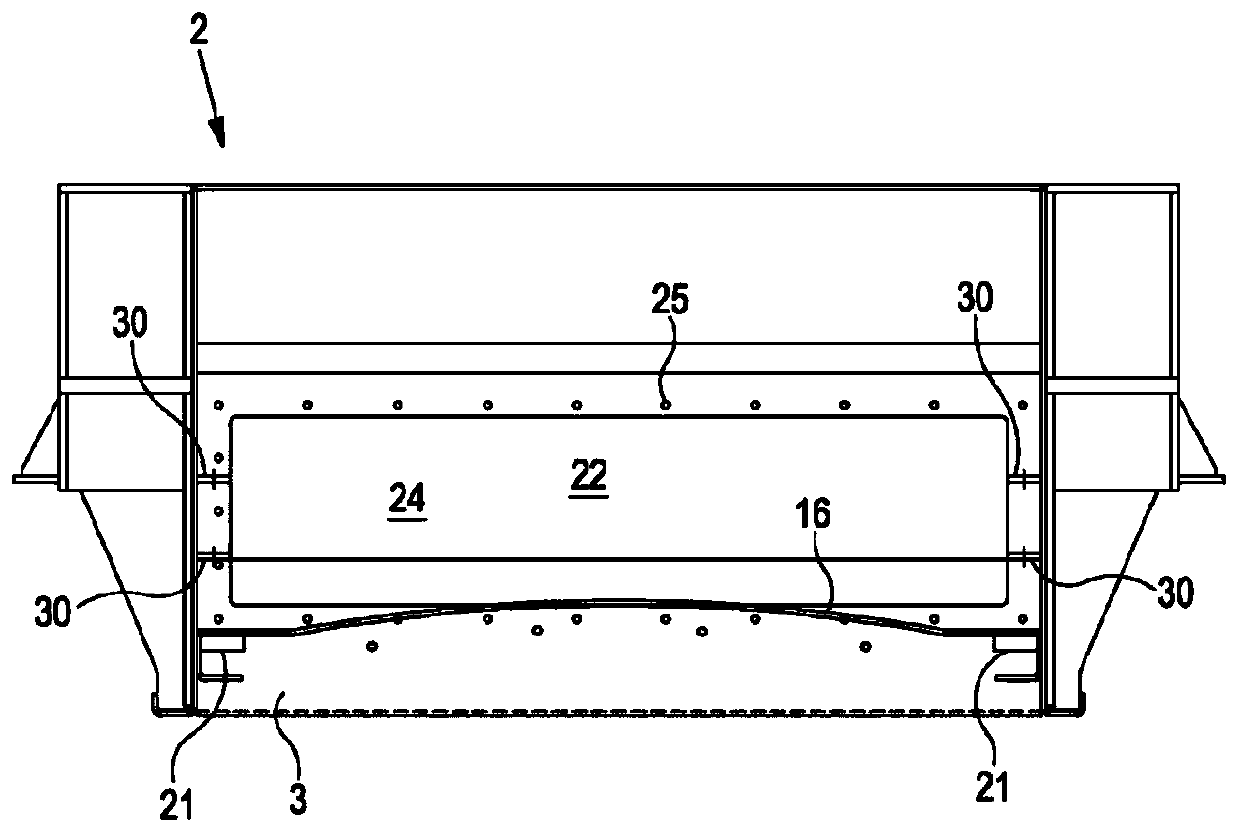

[0082] Figure 2a with 2b A partial cross-section and front view are shown of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap