A high-precision mirrorless lofting process for wind tunnel body

A high-precision, non-prism technology, used in the testing, measuring instruments, instruments, etc. of machine/structural components, can solve problems such as the inability to meet the requirements of lofting accuracy, and achieve the effect of wonderful conception, scientific and reasonable design, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

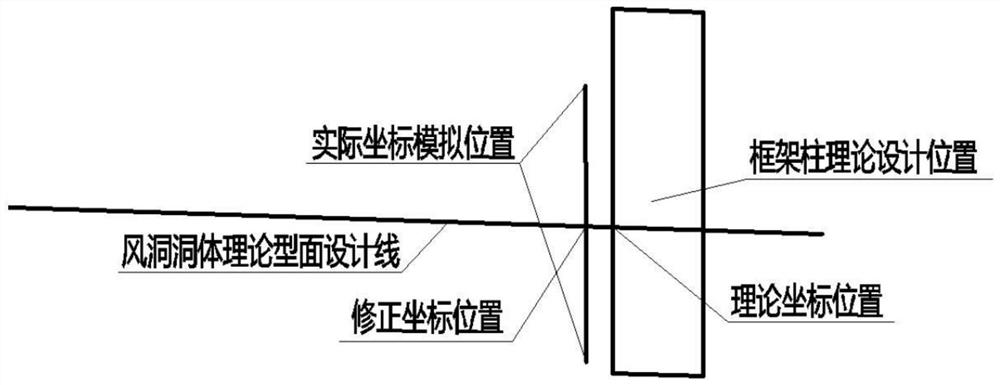

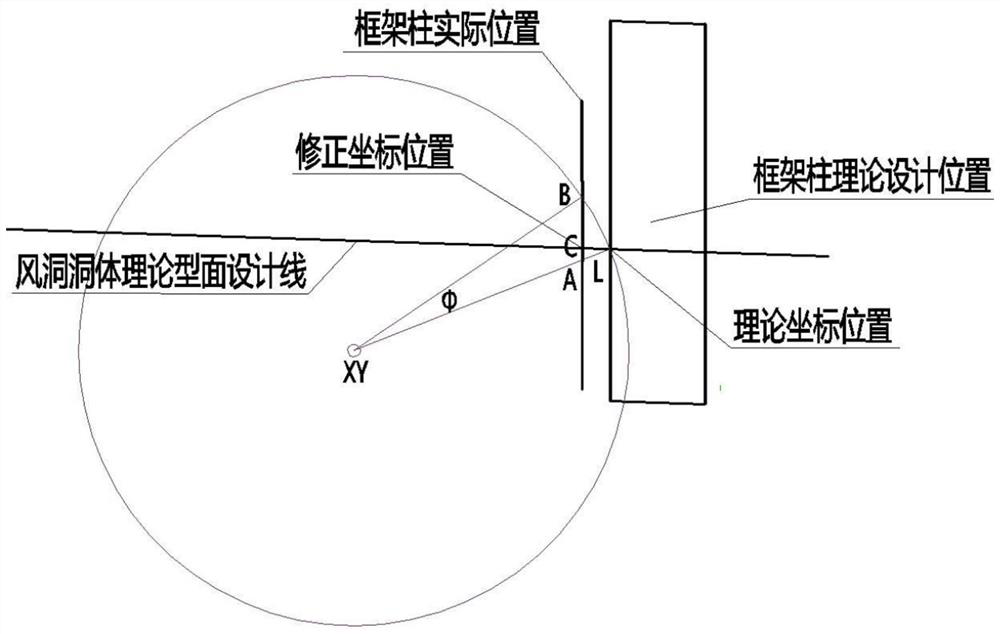

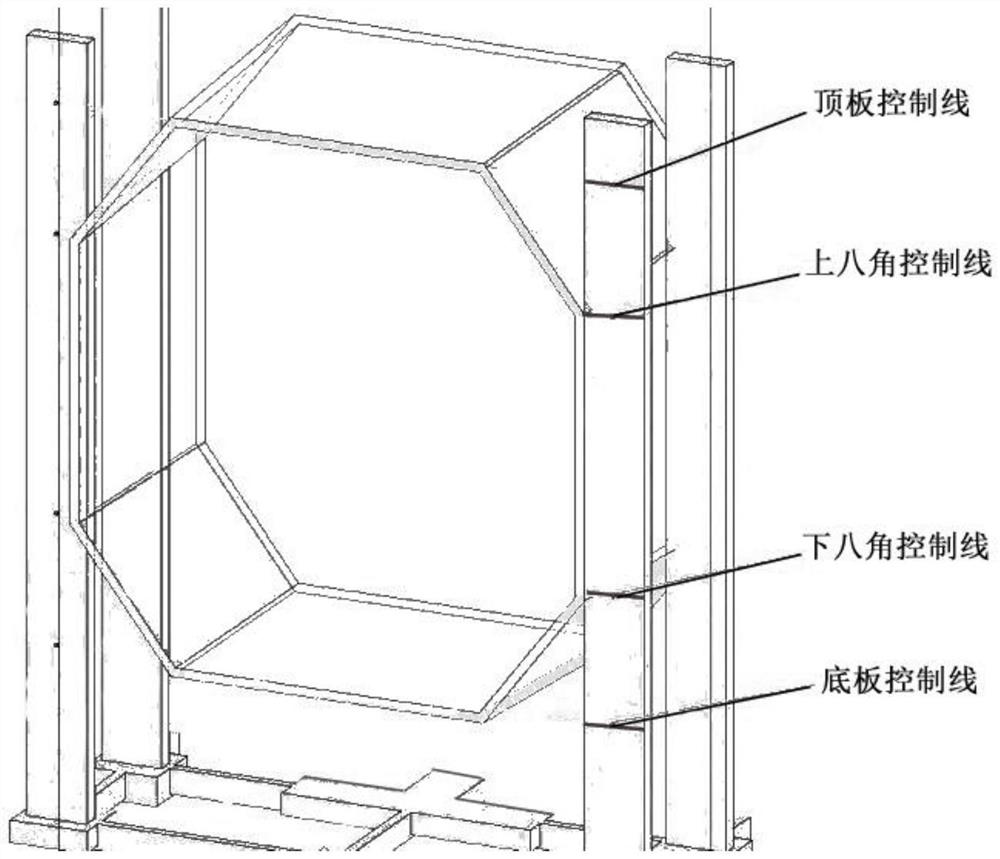

[0022] Such as figure 1 and 2 As shown, a high-precision mirrorless stakeout process for a wind tunnel body provided by the present invention uses the BIM model correction method or the angle and distance double correction method to carry out high-precision mirrorless stakeout for the wind tunnel body. The invention has wonderful conception, scientific and reasonable design, and is convenient to use. It can meet the high-precision non-prism stakeout requirements of the wind tunnel body, overcome the problem that the traditional total station measurement mode cannot meet the stakeout accuracy requirements, and at the same time overcome the inability of the traditional total station prism stakeout. The defects that work on the vertical plane can be applied in a var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com