Self-locking lifting pen

A technology of self-locking and self-locking grooves, which is applied to pen holders, printing, writing utensils, etc., can solve the problems of cumbersome operation and non-self-locking, and achieve the effect of easy assembly, easy replacement of refills, and improved writing experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

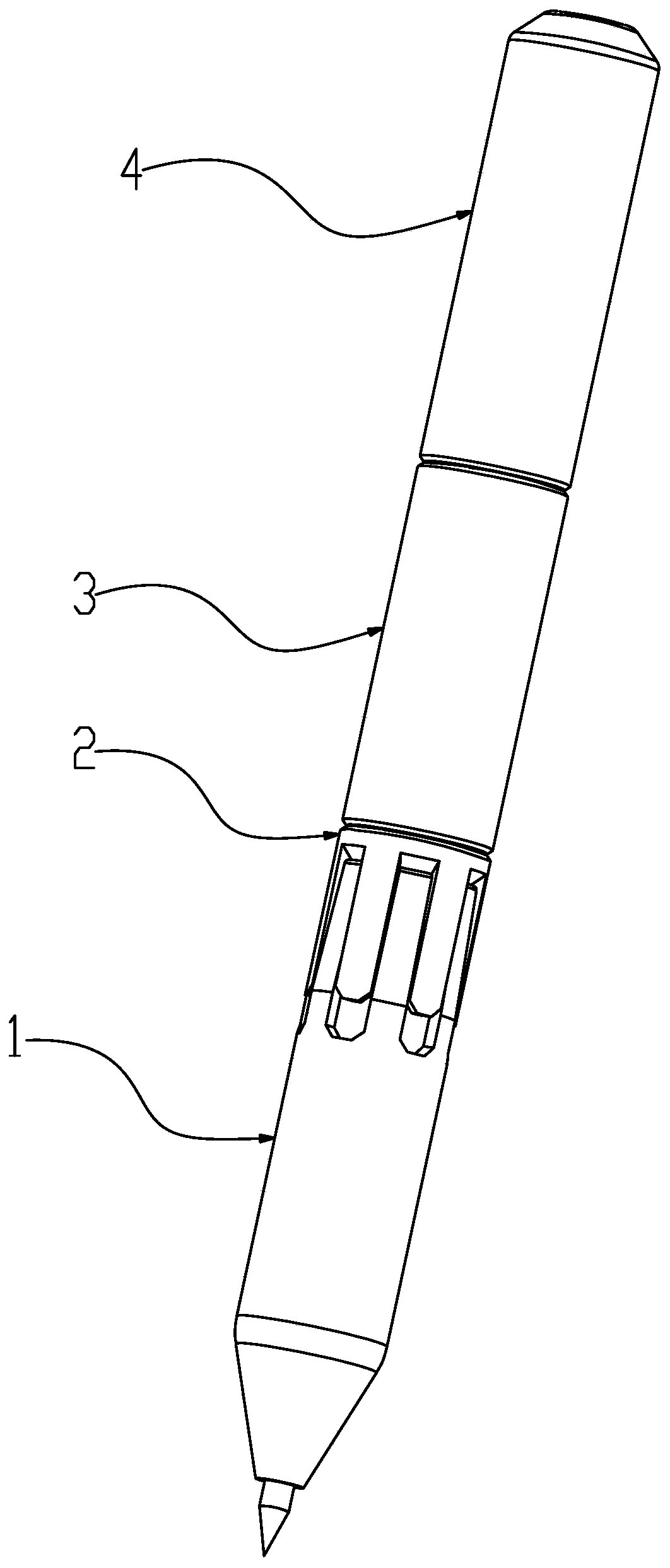

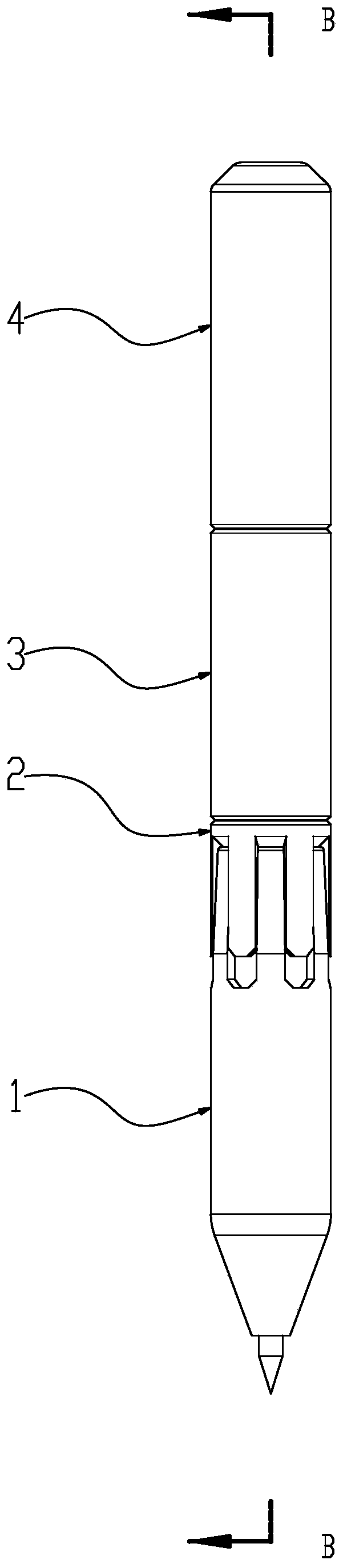

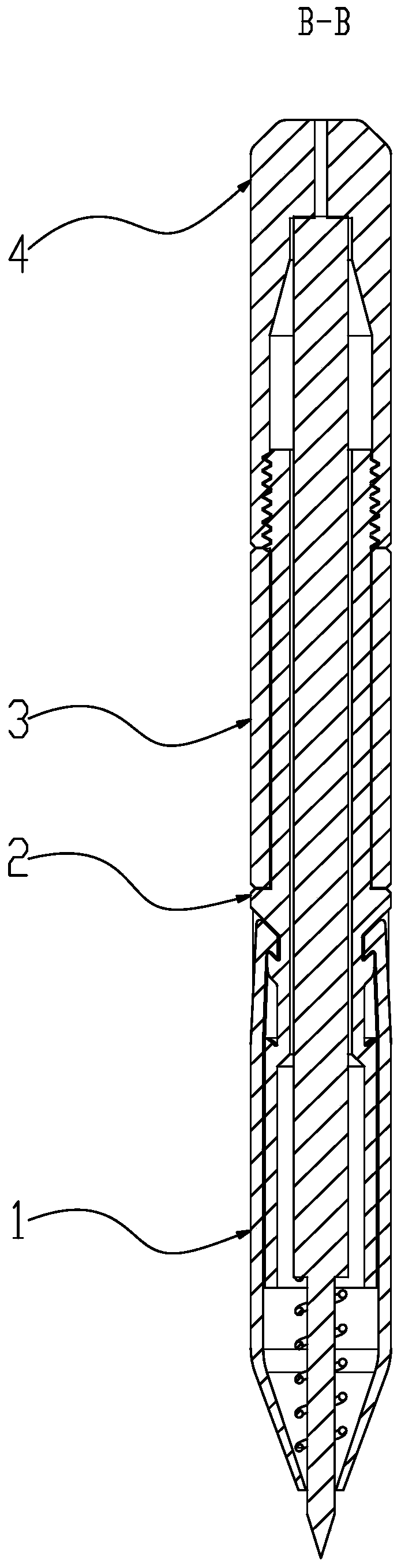

[0052] Such as Figure 1 to 5 The shown self-locking lifting pen includes a front tube 1, an inner rod 2, a pen core 5, a return spring 6 and a tail cover 4. As mentioned above, the return spring 6 is sleeved on the pen core 5, and the pen core 5 is sleeved with the return spring 6 in the front tube 1 and the inner rod 2. The tail cover 4 and the inner rod 2 are connected by threads.

[0053] The inner rod 2 is provided with an inner sliding contact portion 22 and one or more engaging slots 21. The inner sliding contact portion 22 is sleeved in the front cylinder 1. The above-mentioned engagement long groove 21 is composed of an anti-disengagement protrusion 211, a stationary groove 212, a hook protrusion 213, a matching groove 214, and a reset long slope 215 arranged in sequence.

[0054] The front cylinder 1 is extended with engaging columns 121 having the same number as the engaging long grooves 21. The engaging cylinder 121 is provided with an engaging inner protrusion 1211....

Embodiment 2

[0073] Such as Figure 6~12 The shown self-locking lifting pen includes a front tube 1, an inner rod 2, a pen core 5, a return spring 6 and a tail cover 4. As mentioned above, the return spring 6 is sleeved on the pen core 5, and the pen core 5 is sleeved with the return spring 6 in the front tube 1 and the inner rod 2. The tail cover 4 and the inner rod 2 are connected by threads.

[0074] The front cylinder 1 is divided into a lower cylinder 11 and an upper cylinder 12. The lower cylinder 11 and the upper cylinder 12 are connected by engagement, the lower cylinder 11 can freely rotate relative to the upper cylinder 12, and the upper cylinder 12 is extended with the same number of engaging slots 21. 合Column 121. The engaging cylinder 121 is provided with an engaging inner protrusion 1211. The above-mentioned engaging inner protrusion 1211 is moved and locked in the engaging long groove 21.

[0075] The inner rod 2 is provided with an inner sliding contact portion 22 and one or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com