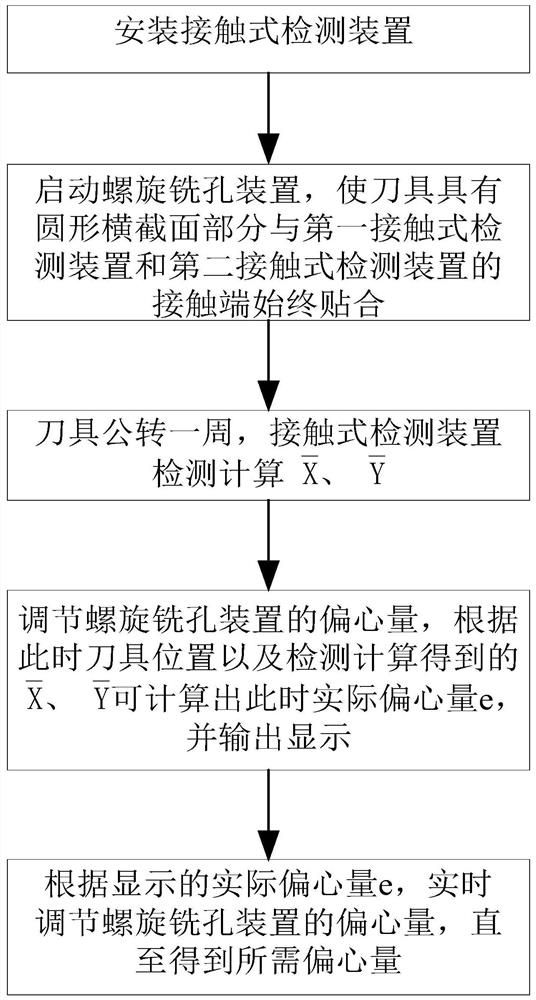

A contact-type real-time eccentricity detection method for a helical milling device

A technology of helical hole milling and detection method, which is applied in the directions of measuring/indicating equipment, metal processing equipment, metal processing machine parts, etc., can solve the problem of the actual value cost of eccentricity that cannot be detected in real time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

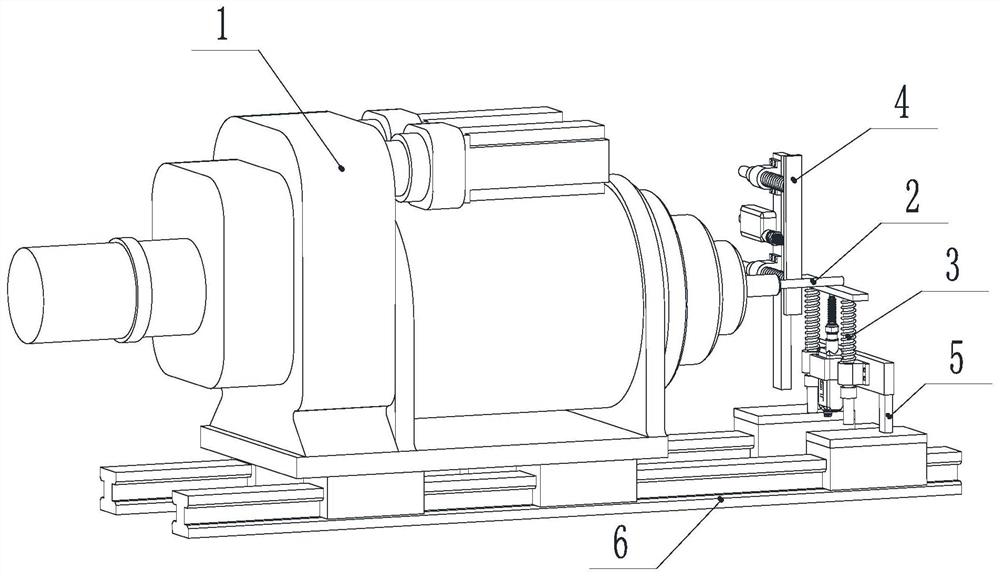

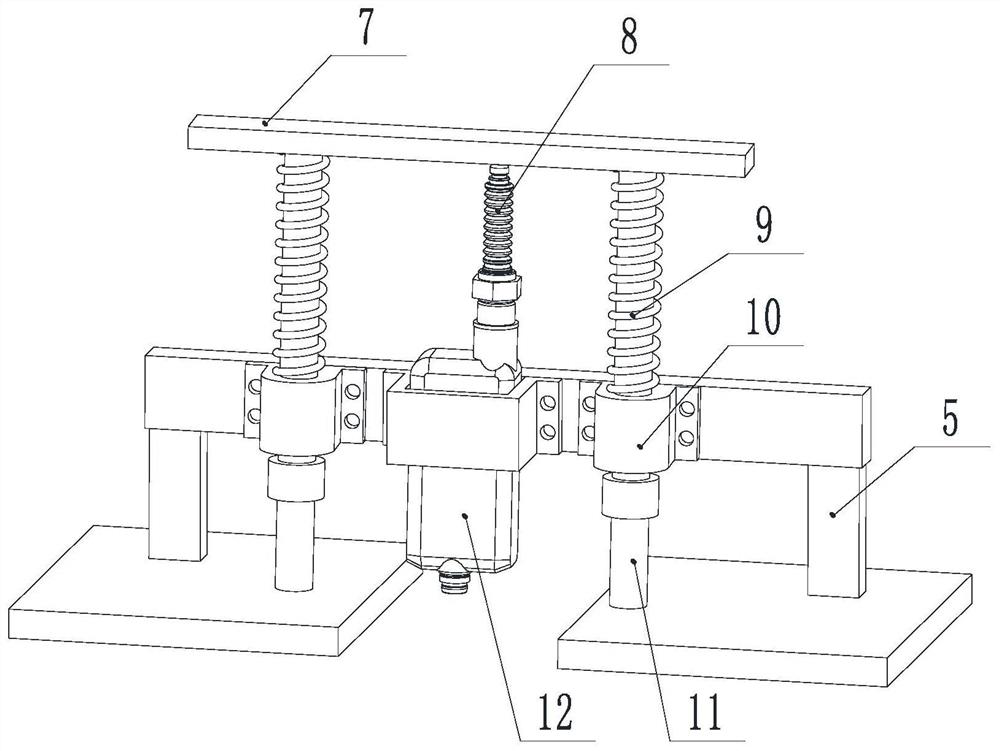

[0059] As additional examples are shown below, such as Figure 5 As shown, the contact detection device includes a first contact detection device 3 and a second contact detection device 4, and the contact ends of the first contact detection device 3 and the second contact detection device 4 can be perpendicular to the tool 2 Moving in the axial direction, the angle θ of the orthographic projection of the contact end movement path of the first contact detection device 3 and the contact end movement path of the second contact detection device 4 in a plane perpendicular to the axis of the tool 2 satisfies 0° Figure 6 As shown, the contact detection device includes a sensor 12, a contact plate 7 (32, 42), an optical axis sleeve 13, a linear bearing 10, a compression spring 9 and a bracket 5, and a measuring head 8 (31, 41) is installed on the front end of the sensor 12. , the measuring head 8 can stretch and move in the axial direction (parallel to the moving path direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com