A non-contact real-time eccentricity detection method for a helical milling device

A helical milling hole, non-contact technology, applied in the direction of measuring/indicating equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the actual value of the eccentricity cannot be detected in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

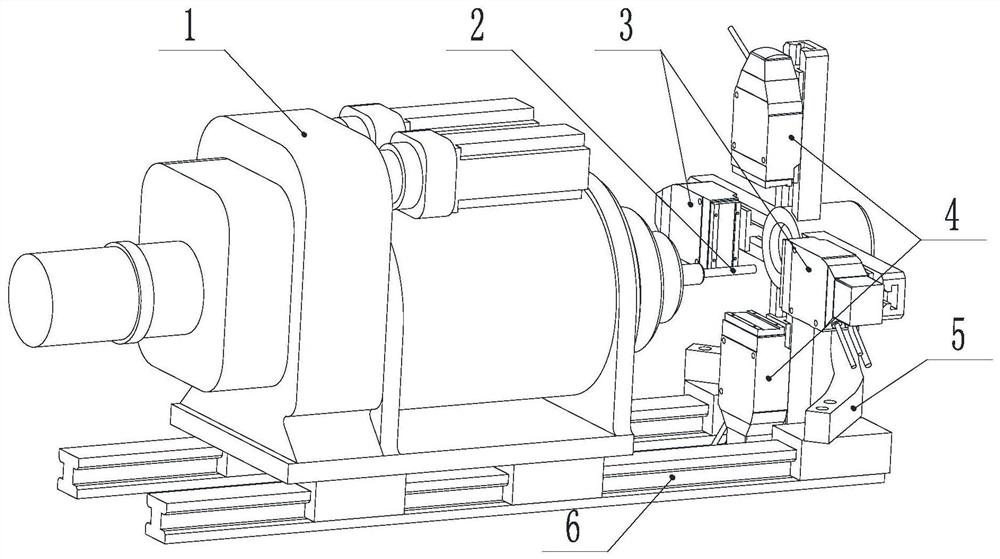

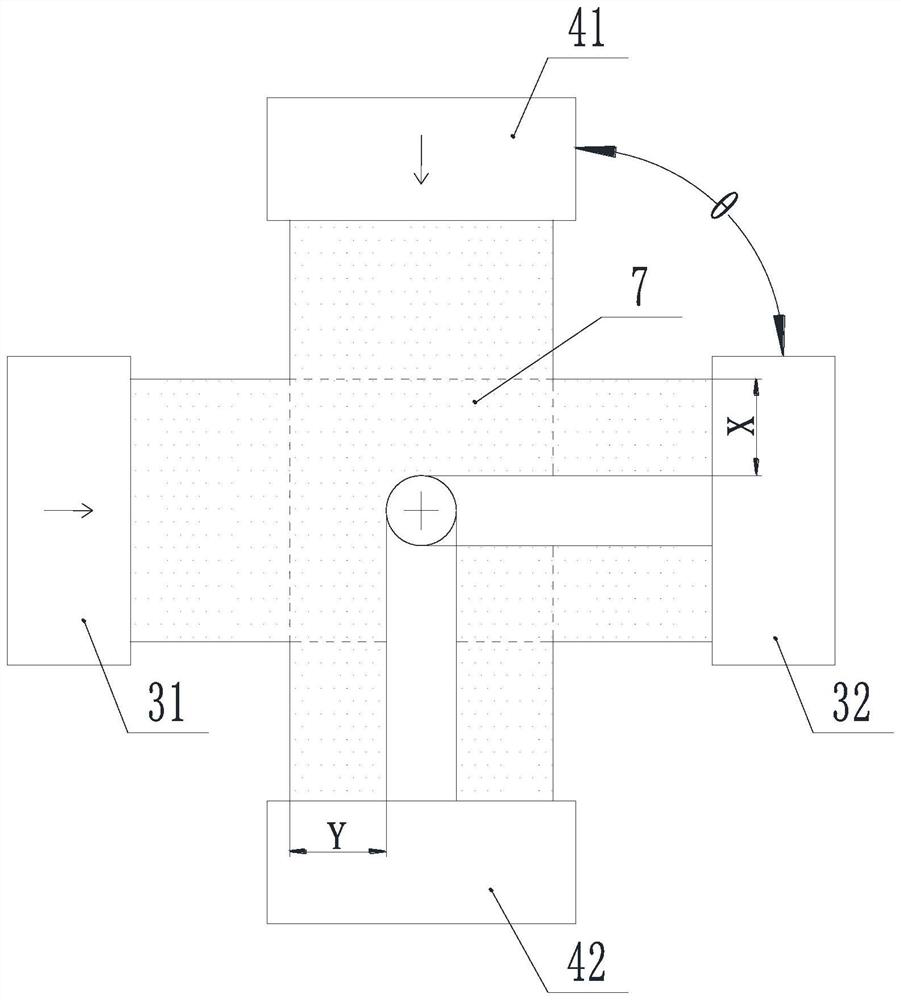

[0055] Such as figure 1 As shown, the laser detection device includes a first laser detection device 3 and a second laser detection device 4, and the first laser detection device 3 and the second laser detection device 4 are installed perpendicularly to each other in a plane perpendicular to the feeding direction of the tool 2. A laser detection device 3 includes a first laser detection device emitting pole 31 and a first laser detection device receiving pole 32 installed on the bracket 5 opposite to each other, and a second laser detection device 4 includes a second laser detection device installed on the bracket 5 opposite to each other. The emitter 41 of the detection device and the receiver 42 of the second laser detection device, the support 5 is installed on the base 6 of the automatic helical milling device 1, and the automatic helical milling device 1 can realize the self-rotation of the tool 2, the revolution of the tool 2, the axial Feed and automatic eccentric adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com