Lifting beam for large container lifting

A large container and lifting beam technology, applied in the field of nuclear power, can solve the problems of increasing the difficulty of assembly for workers and difficult matching, and achieve the effect of convenient and reliable positioning and convenient adjustment and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

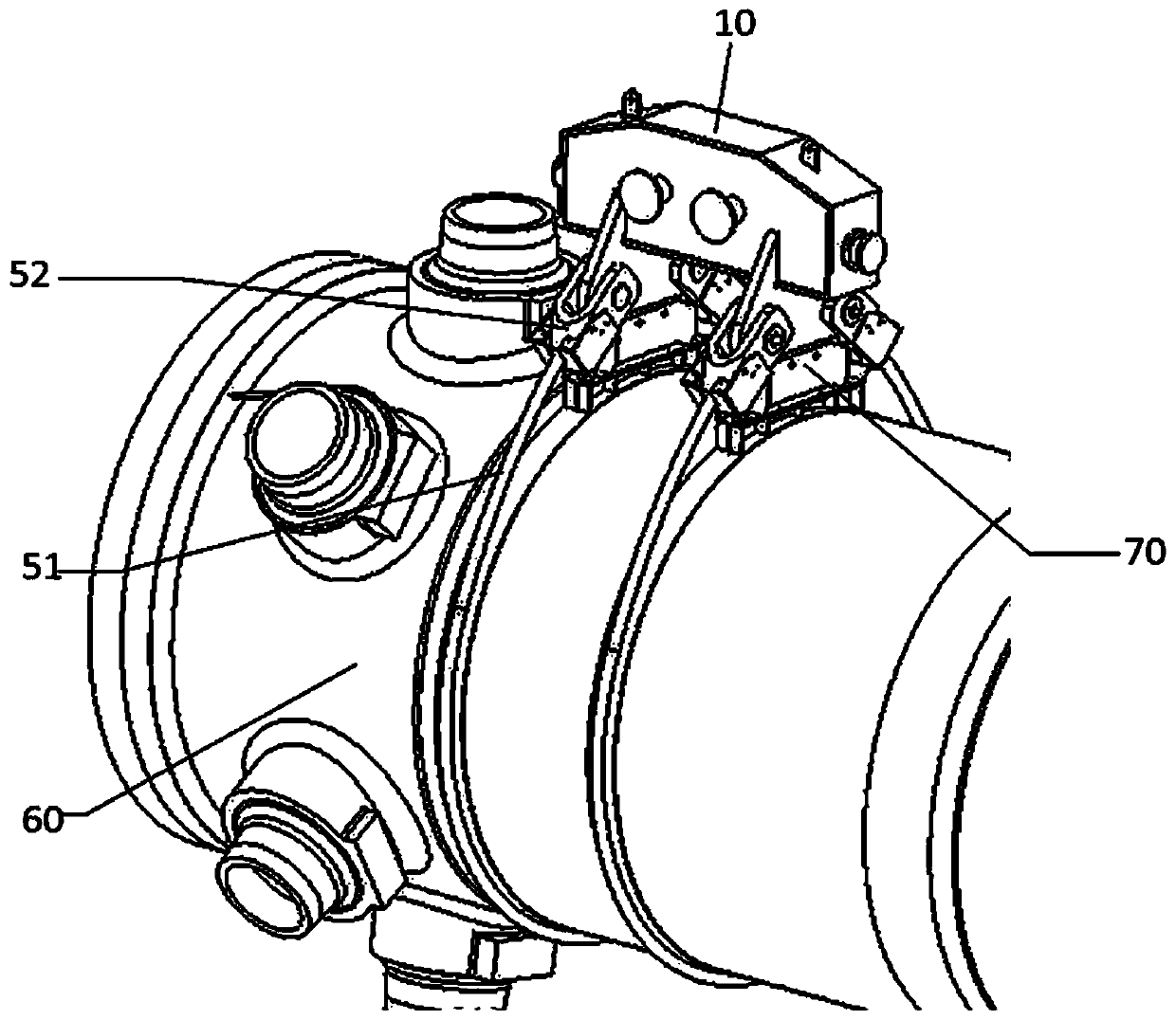

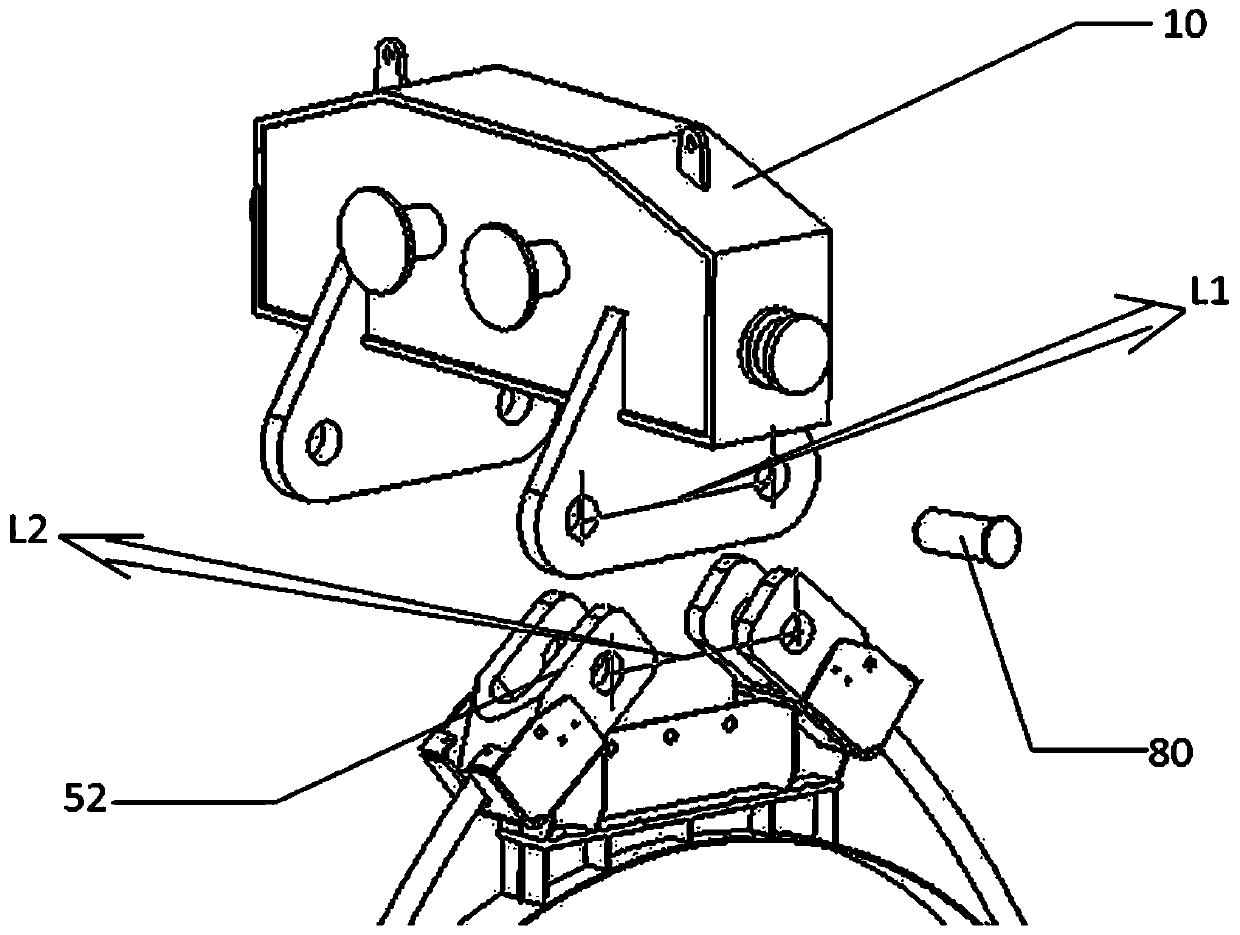

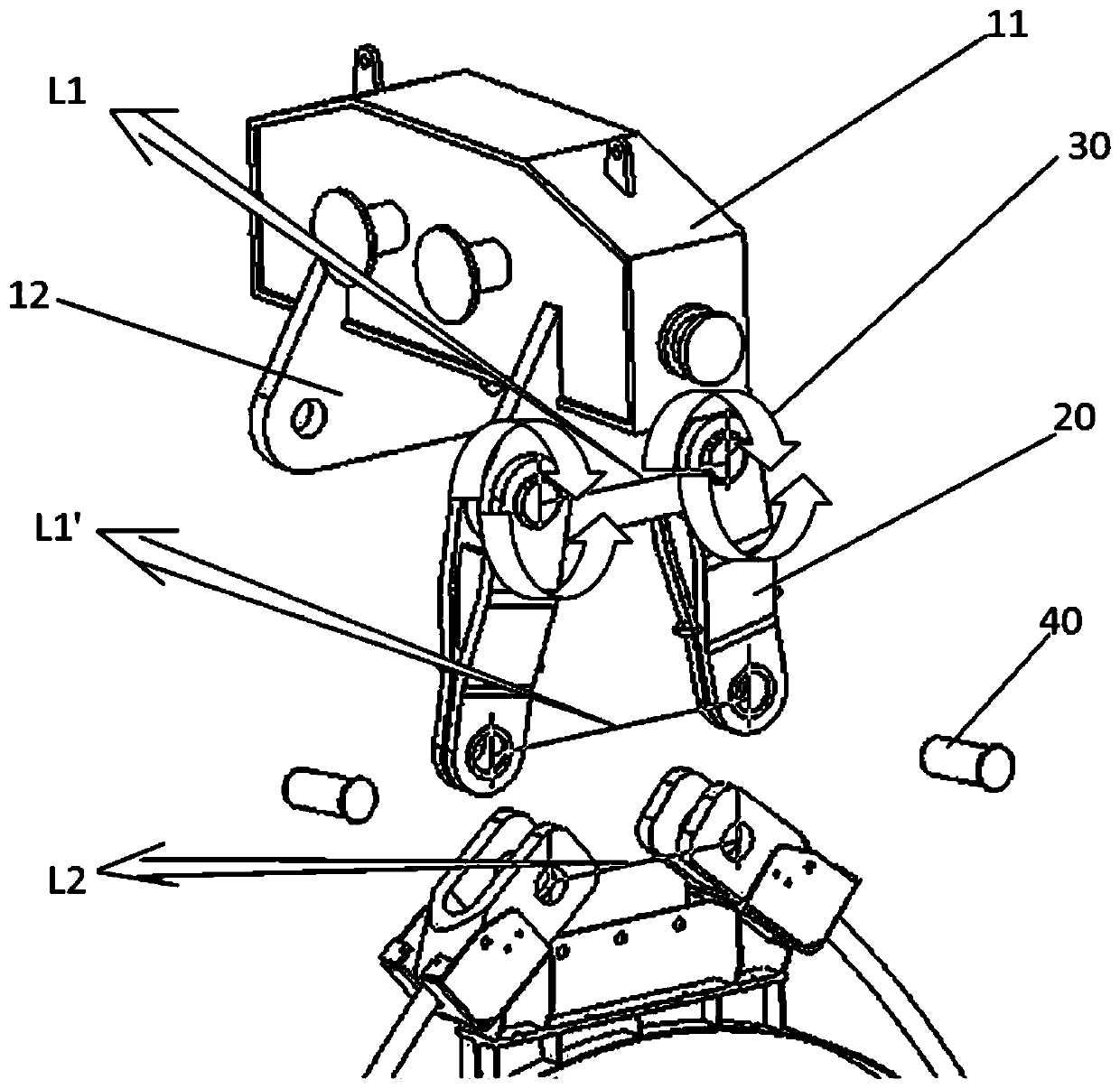

[0019] Such as image 3 As shown, the present invention provides a lifting beam for lifting a large container 60, which includes a main beam 10 and at least one pair of swing beams 20; The pin shafts 30 are movably connected, and can rotate and swing around the respective first pin shafts 30 on the same plane; the steel wire ropes 51 surround the container 60 to be hoisted, and the rope heads 52 at both ends of the steel wire ropes 51 are fixed by the tooling supports 70 on top of the container 60. The bottoms of each pair of swing beams 20 are respectively connected to the rope heads 52 at both ends of a steel wire rope 51 through the second pin shaft 40 .

[0020] In a preferred embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com