A small-scale mechanized coal mining method with flexible cover support in steeply inclined coal seam

A technology of flexible cover support and coal mining method, which is applied in the direction of slitting machinery, mine roof support, ground mining, etc., can solve the problems of mutual "bite frame, large equipment investment, difficult installation of coal mining face, etc., and achieve reliability High, reduce labor intensity and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

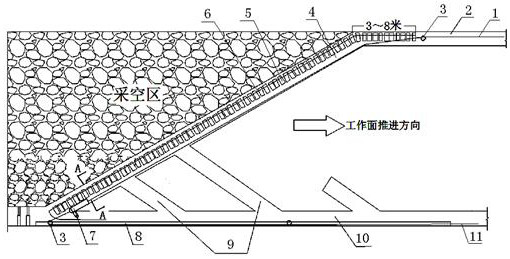

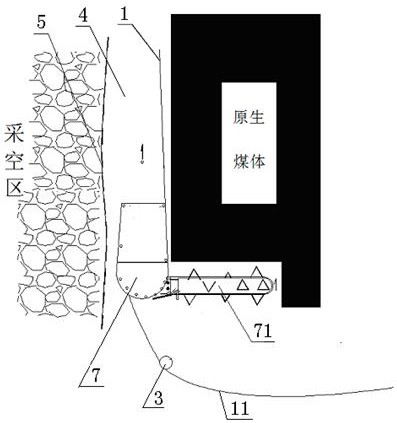

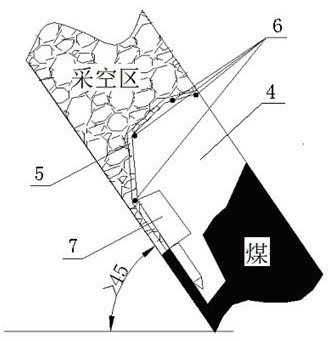

[0028] A small-scale mechanized coal mining method with a flexible cover support in a steeply inclined coal seam, comprising the following steps:

[0029] 1) Under the steeply inclined coal mining area, excavate a horizontal transport chute 10 from outside to inside until the coal mining end at the boundary of the coal mining area, and install a scraper conveyor 8 in the excavated horizontal transport chute 10; On the top corresponding to the horizontal transport trough 10, excavate the horizontal return air trough 2 from outside to inside until it is located at the boundary of the coal mining area; excavate the cutout 4 of the inclined coal mining face so that the cutout 4 of the inclined coal mining face is connected The lower transport chute 10 and the upper return air chute 2;

[0030] 2) On the gob side in the cutout 4 of the inclined coal mining face in step 1), several flexible shield supports 5 are installed sequentially, and four steel wire ropes 6 are used to connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com