Clothing production process

A production process and clothing technology, which is applied in the field of clothing, can solve problems such as easy wrinkles, misjudgments by inspectors, and size errors, and achieve the effects of reducing the occurrence of wrinkles and protrusions, accurate cutting sizes, and improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

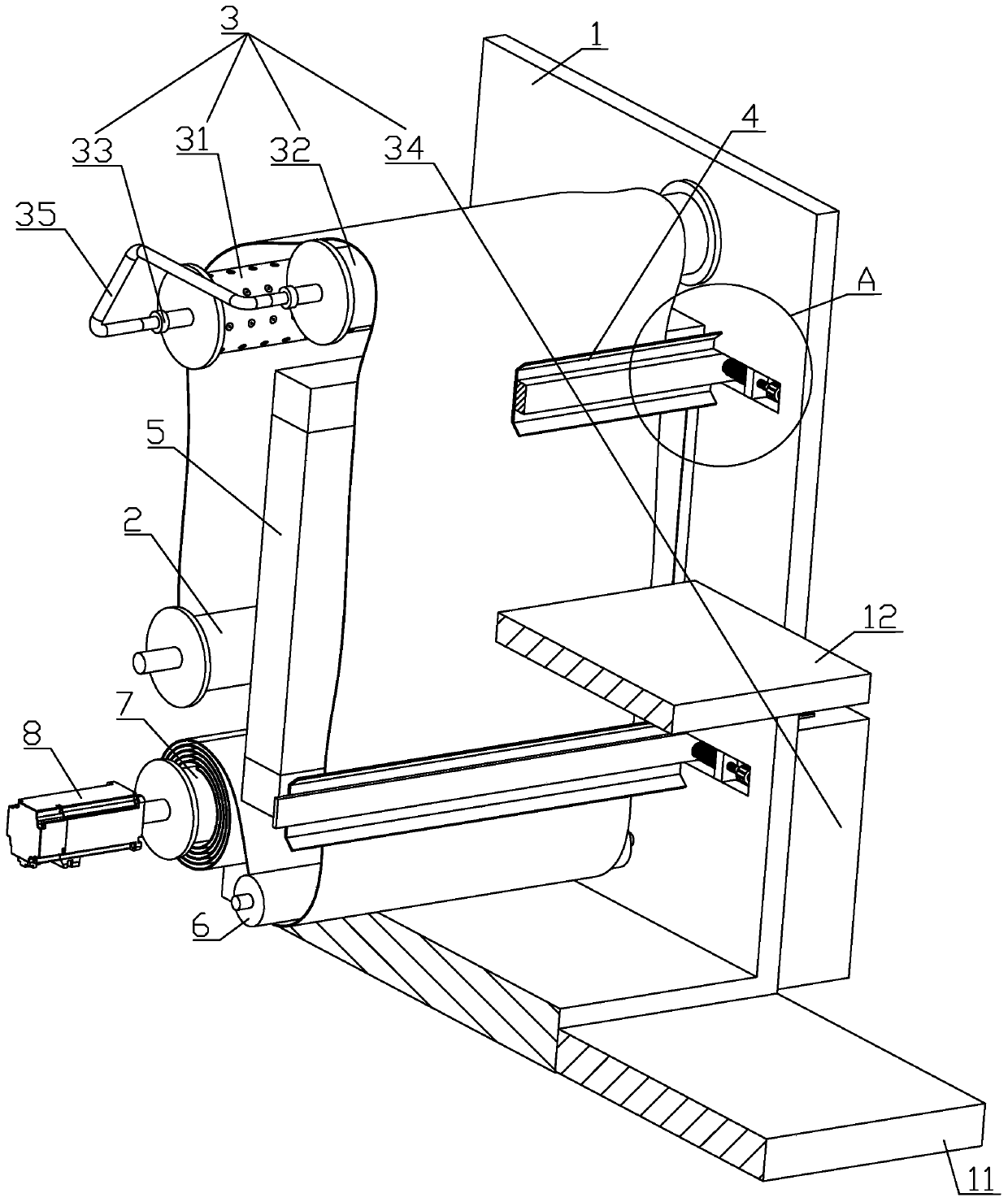

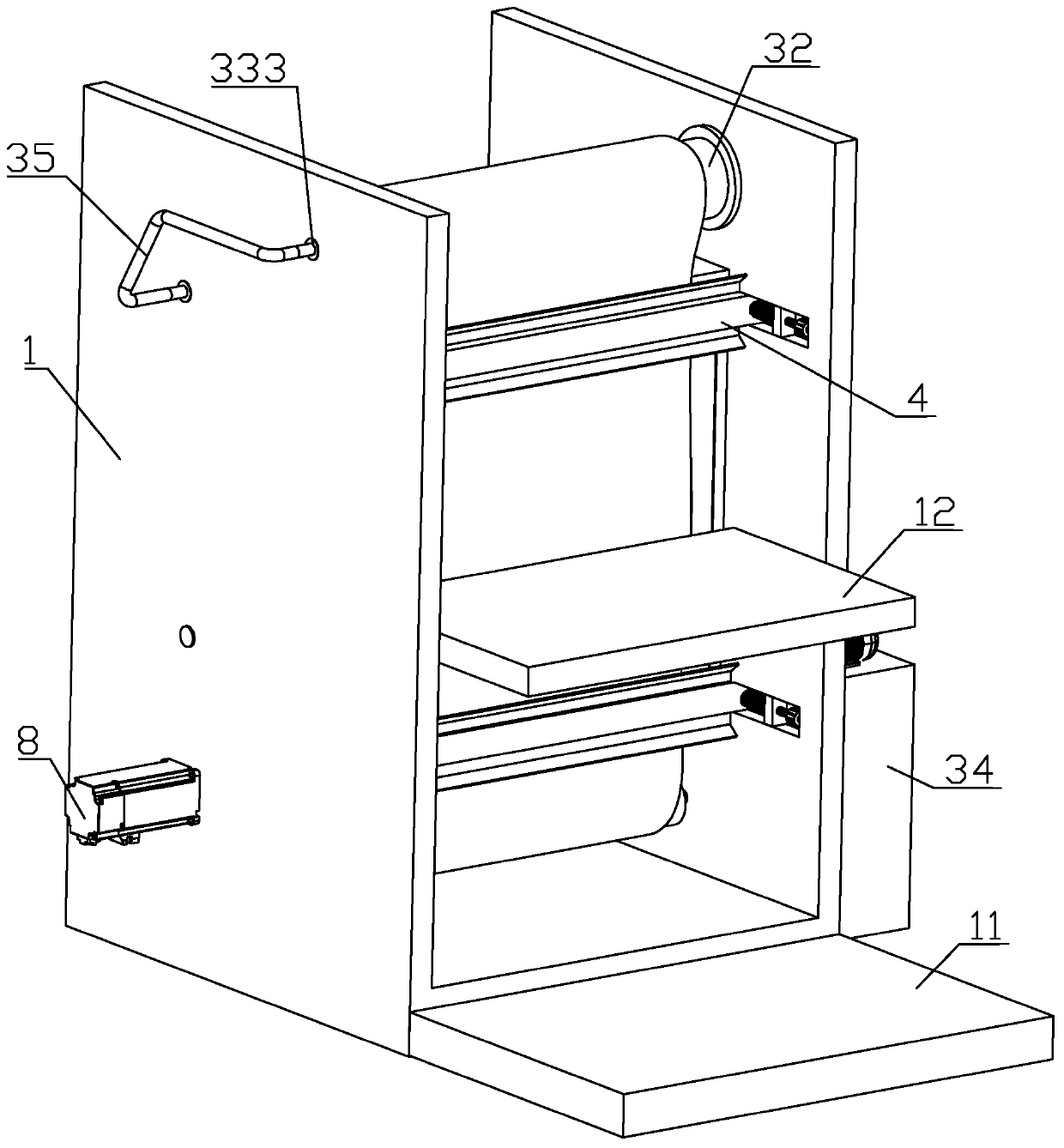

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

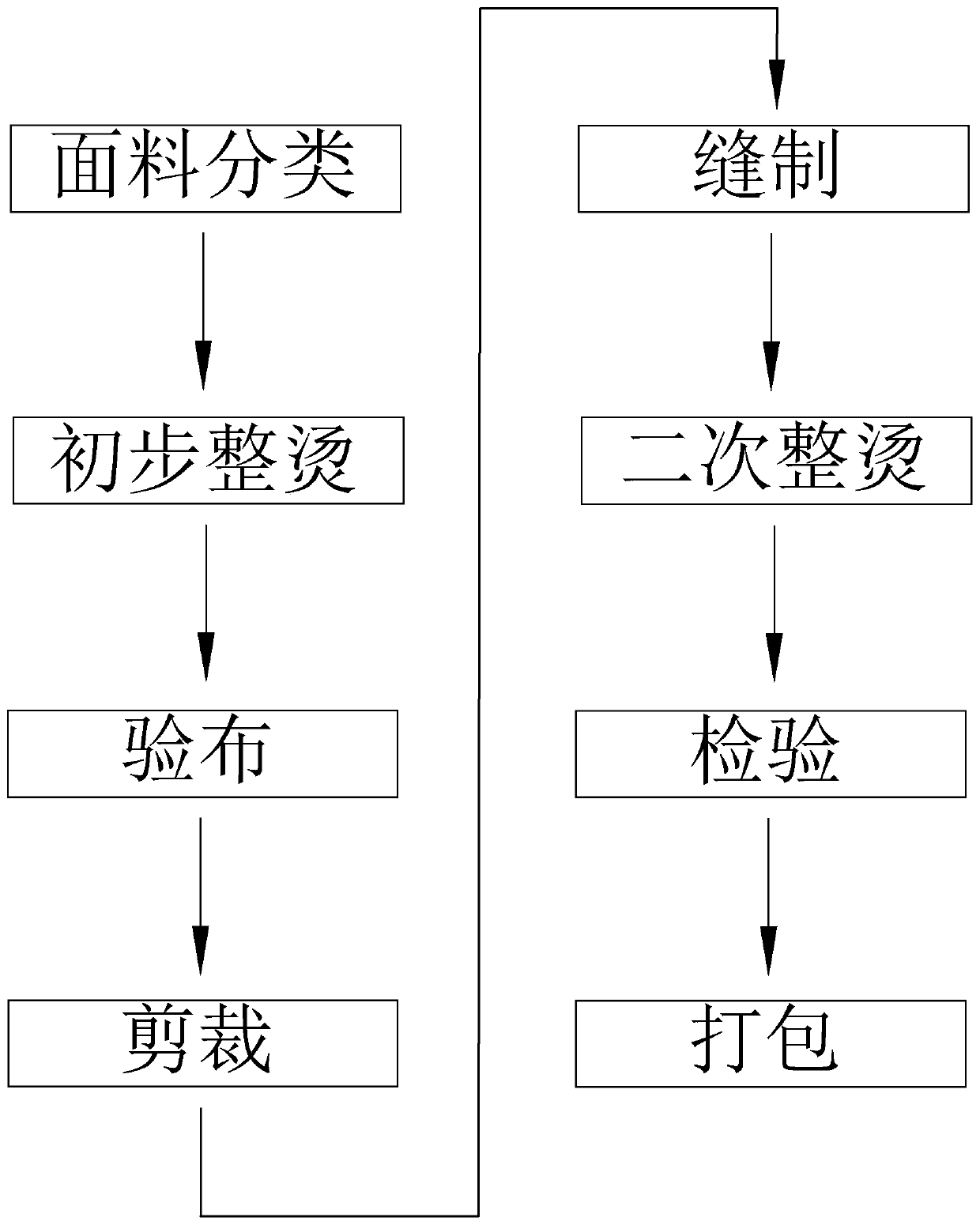

[0045] Such as figure 1 Shown, a kind of clothes production technique comprises the steps:

[0046] a. Fabric classification: divide the fabric into wrinkle-easy fabrics and wrinkle-resistant fabrics, such as cotton and silk fabrics are easy-wrinkle fabrics, and chemical fiber fabrics are wrinkle-resistant fabrics;

[0047] b. Preliminary ironing: level the surface of the fabric that is easy to wrinkle, and put the fabric that is not easy to wrinkle into the existing process;

[0048] c. Cloth inspection: inspect the fabric after leveling;

[0049] d. Cutting: Cut the fabric after cloth inspection according to the layout chart;

[0050] e. Sewing: put the cut fabric into the machine sewing operation line;

[0051] f. Secondary ironing: iron the finished clothes after sewing to make the surface of the finished clothes smooth;

[0052] g. Inspection;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com