Composite wood flooring

A composite wood and floor technology, applied in elastic floors, buildings, floors, etc., can solve problems such as injury, unsafe use, and difficulty in disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

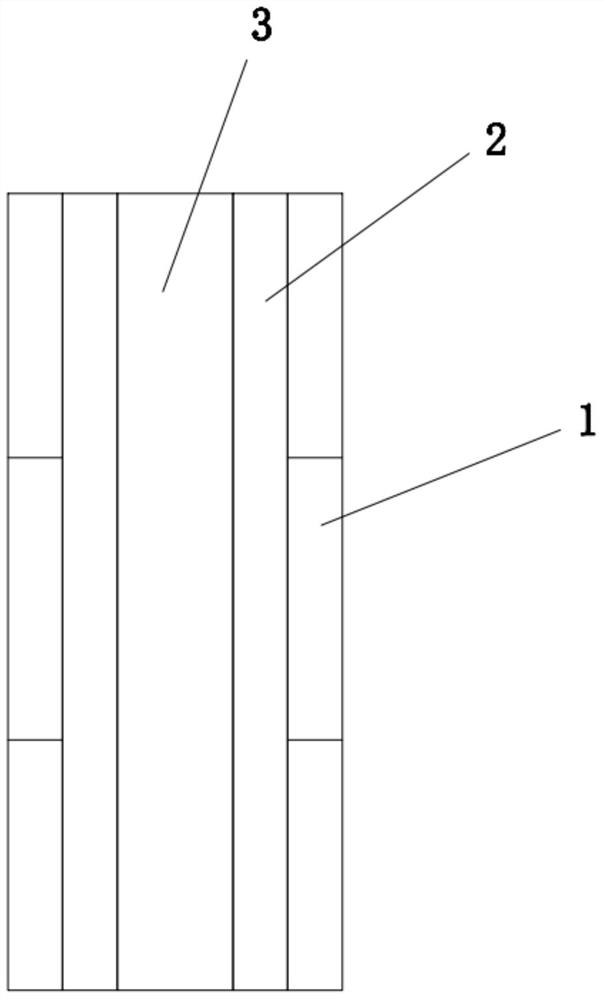

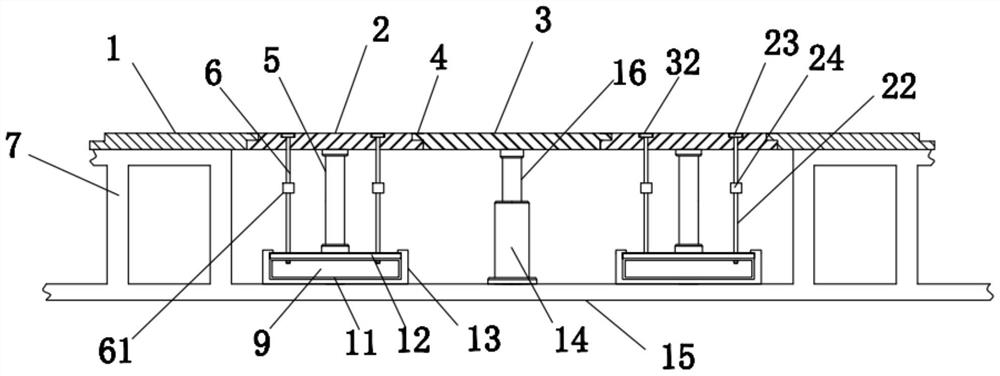

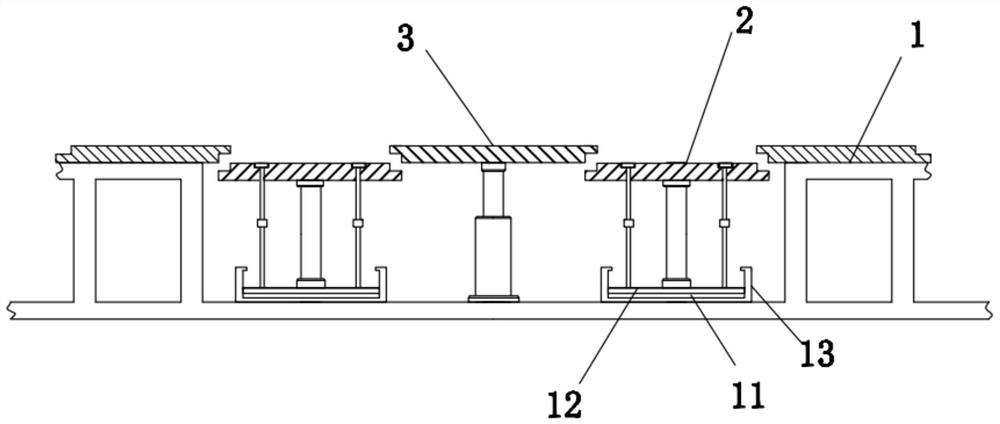

[0018] Such as figure 1 and figure 2 As shown, the composite wood floor, including the floor set laid on the ground, can be set around the bed body, so that when it falls, it will contact with the specific area set up to play a role of safety protection; in this embodiment , the floor set includes a first floor 1, a second floor 2 and a third floor 3, the third floor 3 is set between the second floors 2 on both sides, the third floor 3 is located in the area that needs vibration reduction, the first floor 1 is arranged on the periphery of the second floor 2 to surround the entire second floor 2. When the second floor 2 on both sides of the third floor 3 is lowered, the restrictive force at the bottom of the third floor 3 is removed. When the third floor 3 is in contact, the third floor 3 can achieve the purpose of buffering, and when the second floor 2 does not fall, it cannot be pressed down when stepping on the third floor 3 at this time, and the second floor 2 is stepped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com