sawing machine for miter cuts

A sawing machine and bevel cutting technology, applied in the field of sawing machines, can solve the problem of unresolved clamping problems of clamps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

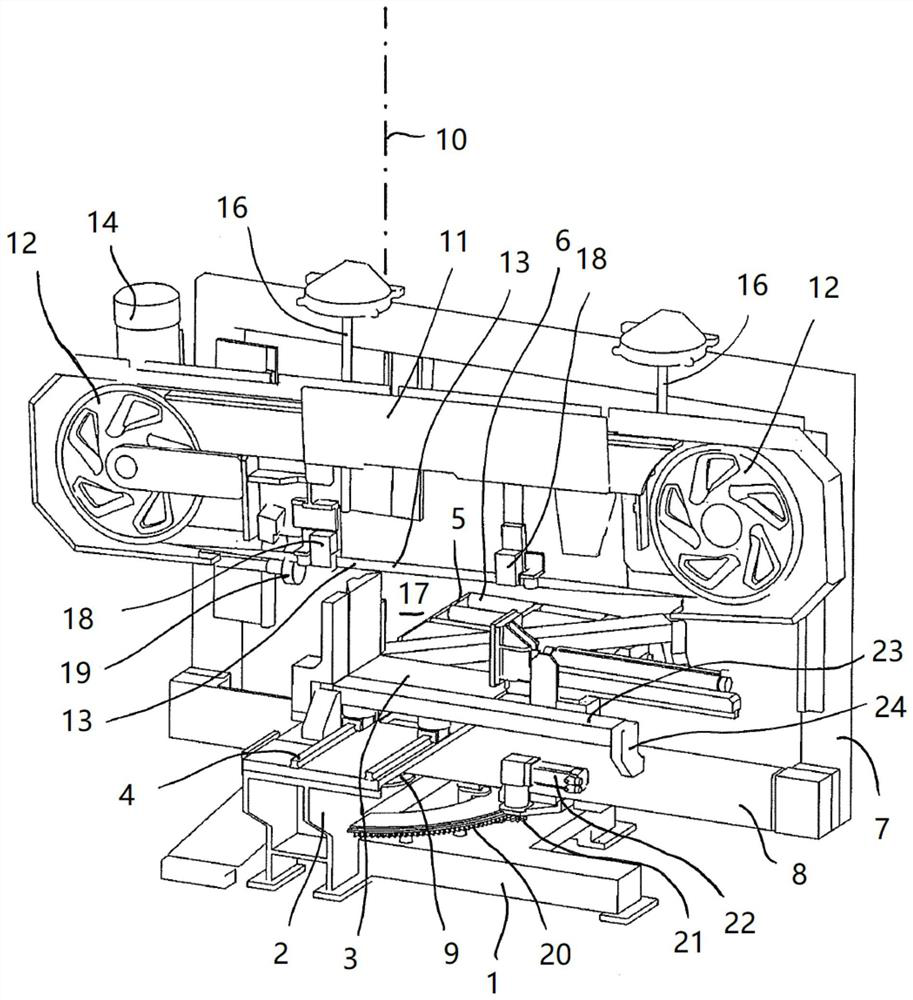

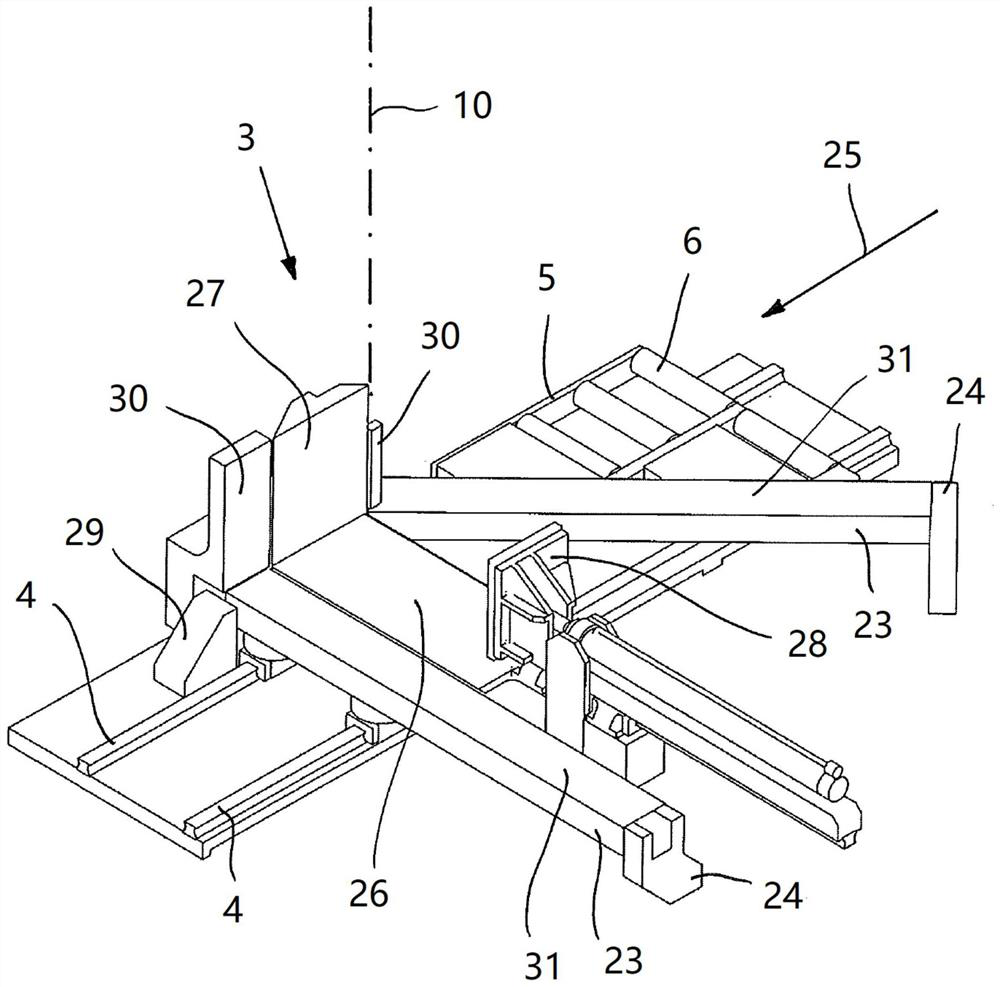

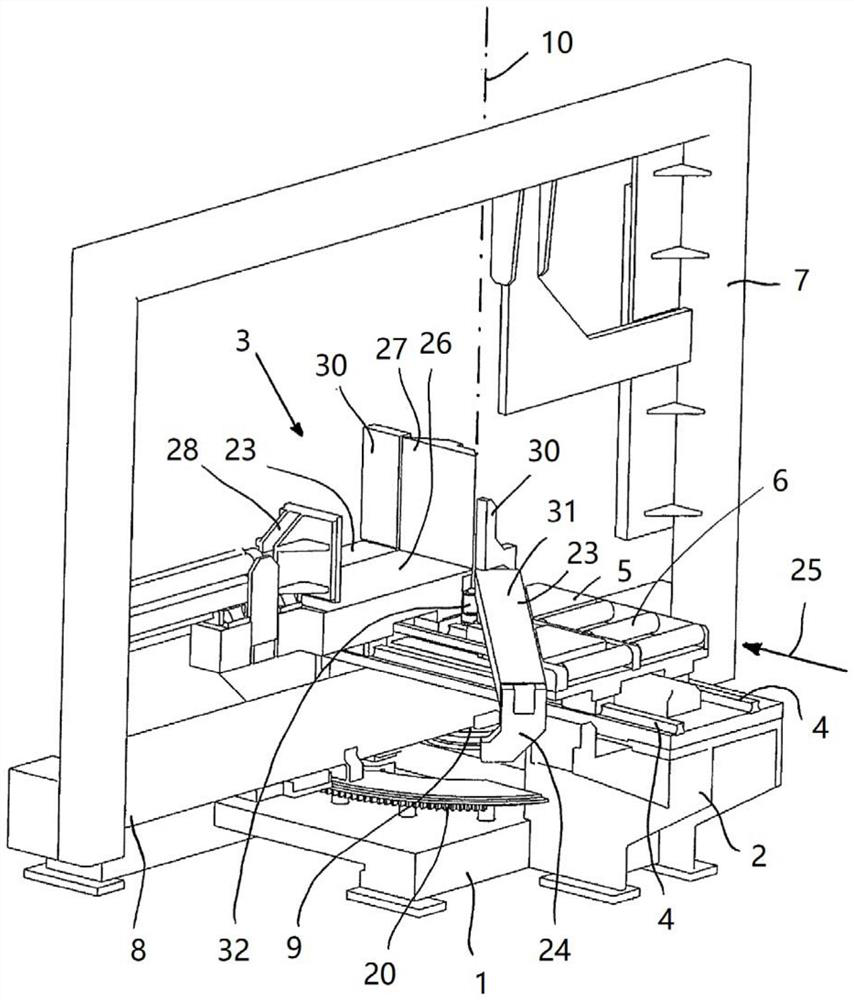

[0058] In order to better understand the housing and accessories omitted here of the present invention, figure 1 An embodiment of a sawing machine designed according to the invention for mitering metal workpieces is shown in a schematic perspective view, comprising a stationary base 1 with a support for a sawing table 3 The seat 2 and the sawing table 3 can move along the two rails 4 on the support 2. In this illustration, the infeed side of the sawing machine is located at the rear, on which infeed side the infeed raceway 6 is fastened to the support 2 of the base 1 as the conveying path 5 .

[0059] On the base 1, a bracket 7 is pivotably fixed on the base 1 in the form of a frame, here the lower beam 8 of the bracket 7 cooperates for this purpose with a pin in a radial bearing 9 (not visible) and can The straight axis 10 pivots.

[0060] The support 7 carries the saw upper part 11 , which has two running wheels 12 around which the saw band 13 runs continuously. exist fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com