Method for producing dental prostheses

A kind of imitation, dental technology, applied in the direction of dentistry, dental prosthesis, medical science, etc., can solve the problem of long milling time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

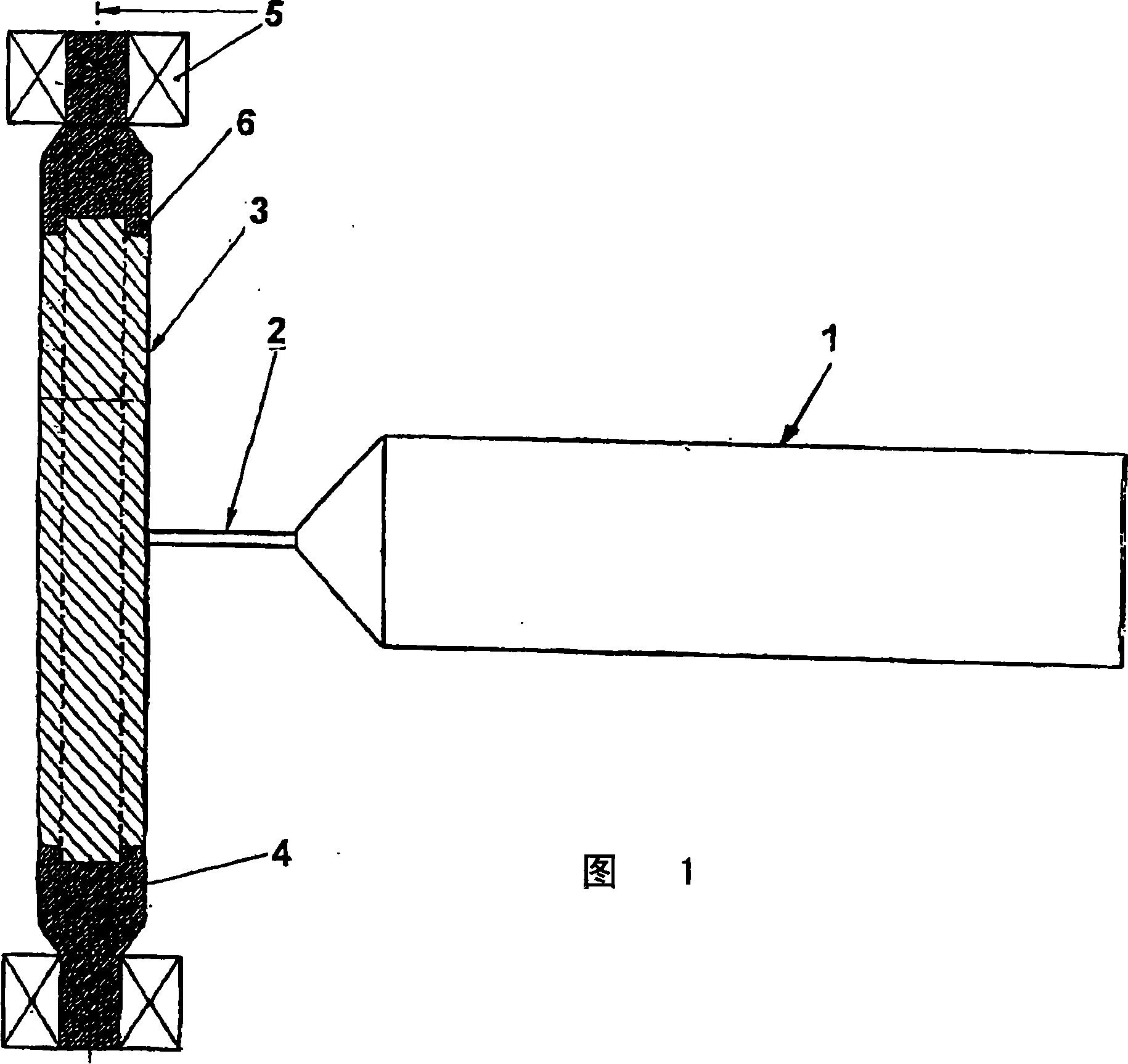

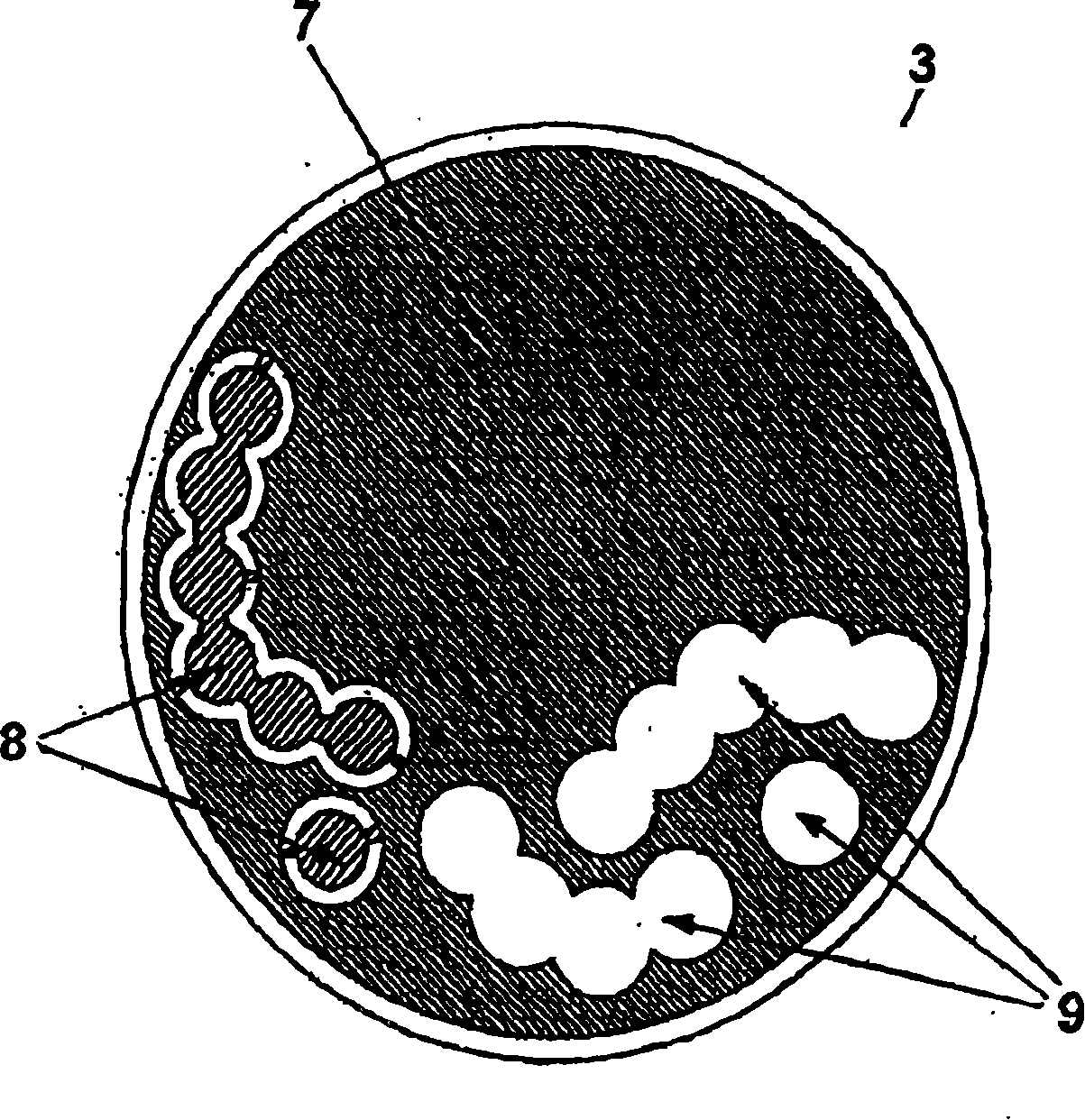

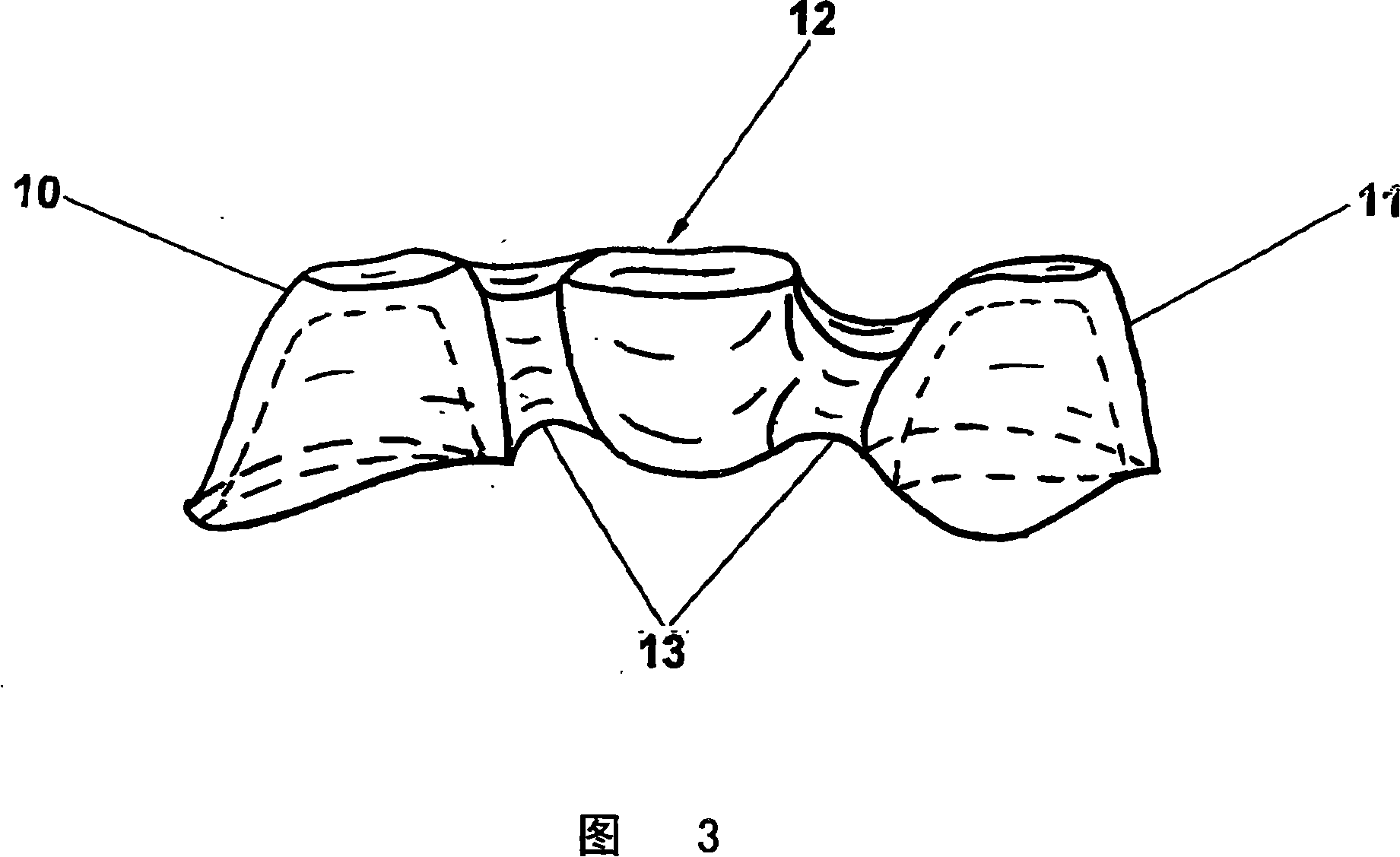

[0021] figure 1 The arrangement of the machine for the machining of a blank 3 is shown. As mentioned several times above, the blank 3 is a plate-shaped structure and is vertically clamped in a clamping device 4 in at least one CAD / CAM processing station, whereby the spindle drive motor 1 and the associated milling cutter 2 The face of the blank 3 is machined in the horizontal direction. The blank 3 is clamped rotatably about an axis 5 in a clamping device 4 , wherein the blank 3 has a concentric turned annular groove 6 in the circumferential direction, to which the clamping device 4 acts in a non-positive connection . The horizontal machining of the blank 3 enables the closed and cavity shapes of the individual tooth imitations to be machined. Here the working positions are predetermined and converted to optimal control. The processing of the blank can be realized not only by CAD / CAM, but also by other cutting systems. The process preceding this machining process can be b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com