Rotary air head type nori slice feeding device

A supply device and air head technology, applied in transportation and packaging, object separation, pile separation, etc., can solve the problems of poor application, complex structure, and poor working reliability in special occasions of deep processing of laver, and achieve no need The effect of manual intervention, simple overall structure, and rapid and continuous supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

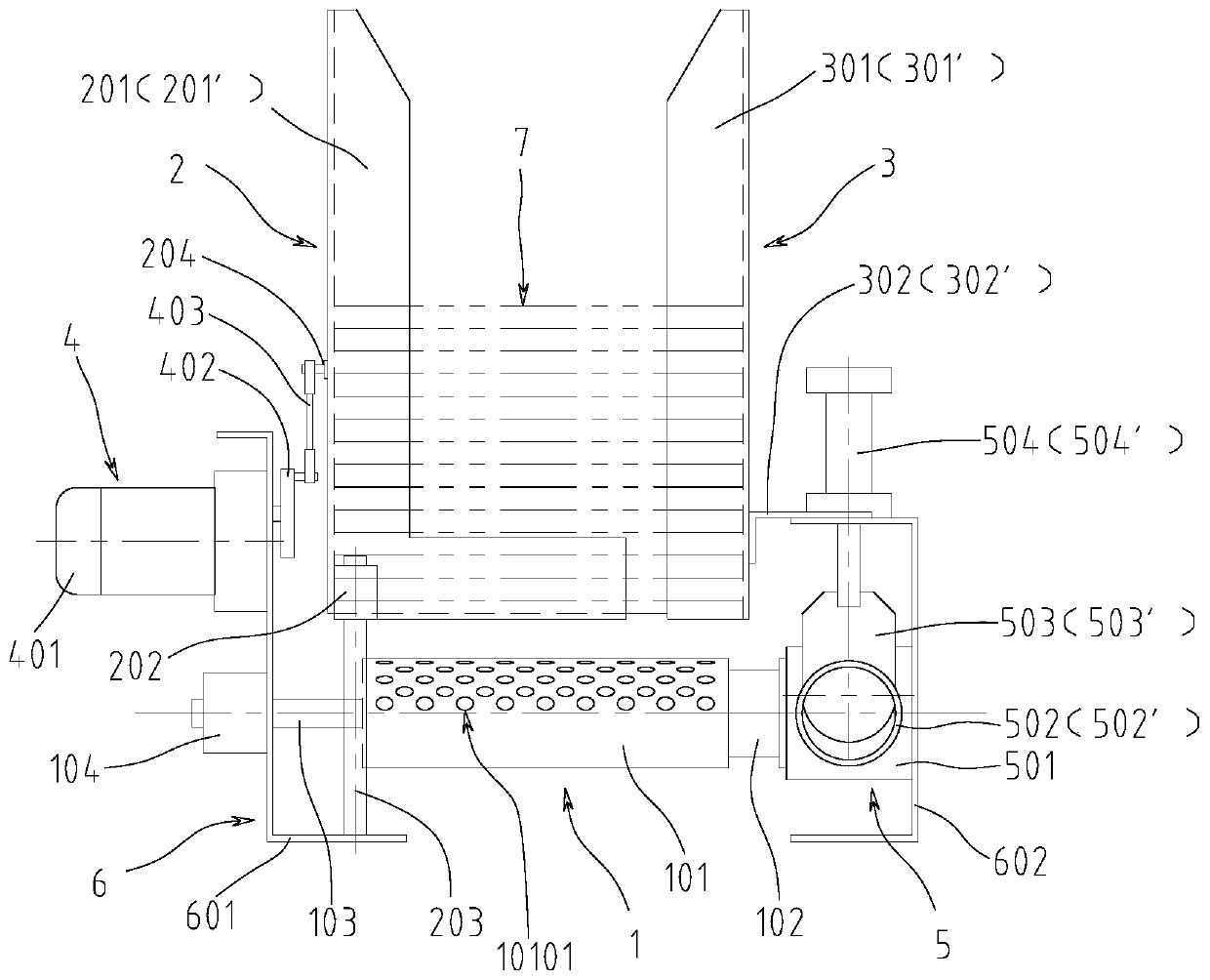

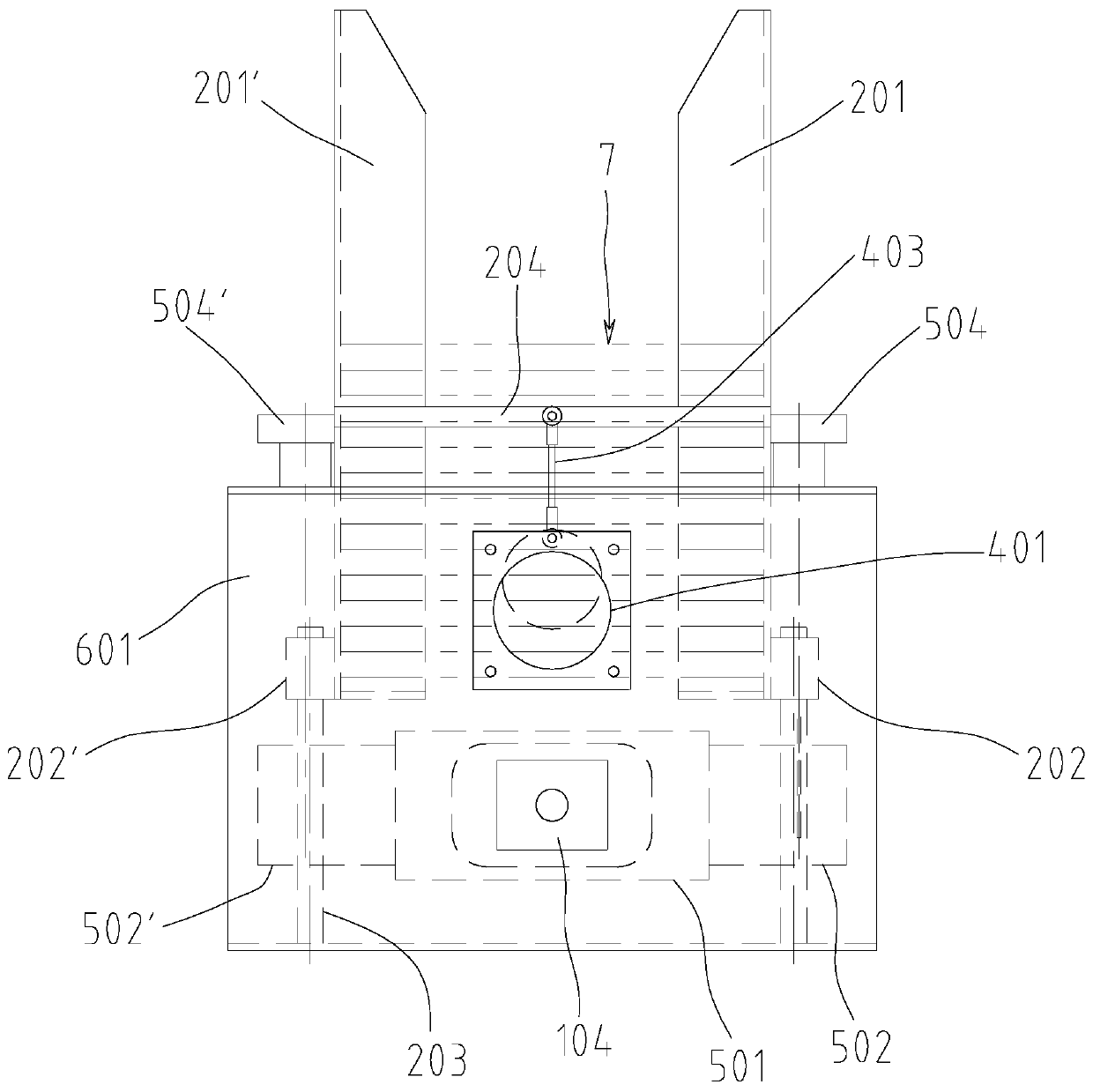

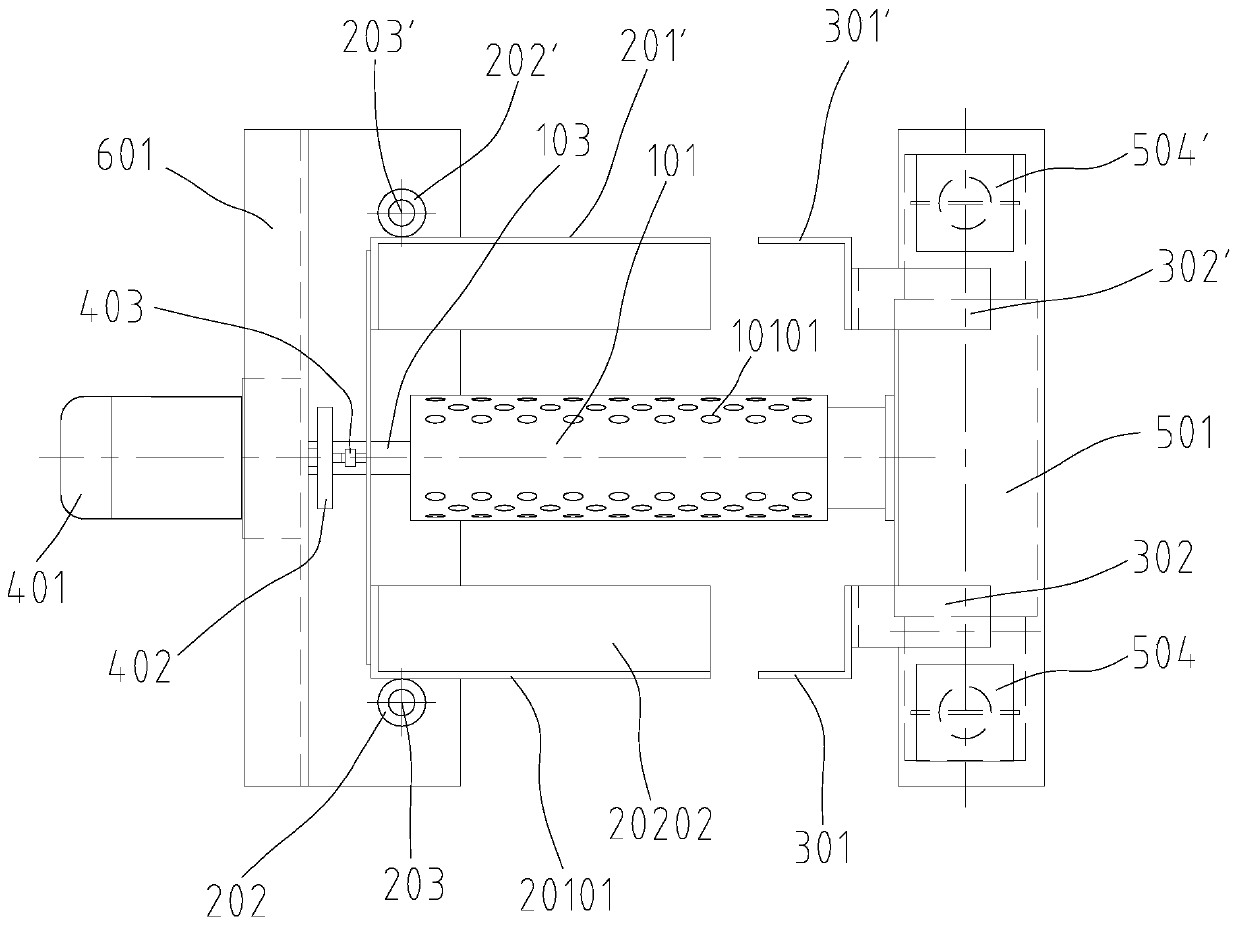

[0021] Embodiment 1: see figure 1, a rotary air head type laver sheet supply device, which includes an air head assembly 1, a movable rack assembly 2, a fixed rack assembly 3, a drive assembly 4, an air distribution assembly 5 and a frame assembly 6, wherein the drive The assembly 4 is fixedly installed on the frame assembly 6, and the movable material rack assembly 2 is installed on the frame assembly 6 by sliding up and down through the guide device, and is driven up and down by the drive assembly 4. Move; the air head assembly 1 is rotatably installed on the frame assembly 6 according to the horizontal direction of its rotation axis, one end of the air head assembly 1 is linked with the power drive device, and the air head assembly 1 The other end of the air distribution assembly 5 is connected to the air distribution assembly 5, and the air distribution assembly 5 is fixedly installed on the frame assembly 6 to support the air head assembly 1 for rotation and communicate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com