Water inlet channel interception device for hydroelectric power generation equipment

A technology of power generation equipment and interception devices, which is applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve the problems of grid blockage, insufficient water intake of generator sets, etc., and achieve the effects of easy cleaning, simple structure, and convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

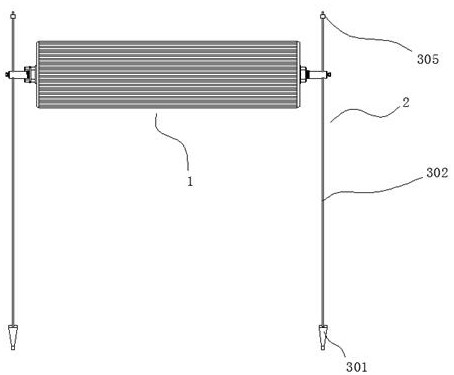

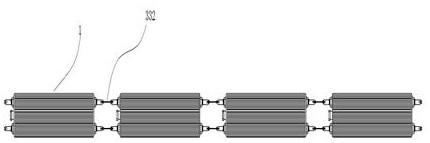

[0042] refer to Figure 1 to Figure 6 As shown, a water conservancy power generation equipment inlet channel interception device shown includes a floating device 1, and a tightening device 2 for tightening the floating device 1;

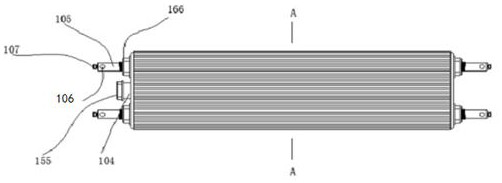

[0043]The floating device 1 includes a floating bucket 101, a cavity 102 is formed inside the floating bucket 101, and a nozzle 104 communicating with the cavity 102 is formed at one end of the floating bucket 101 by injection molding. An end cap 155 is threadedly connected to the nozzle 104, and a pipe hole 103 is formed by injection molding at the end face of the buoyant bucket 101, the pipe hole 103 runs through the buoyant bucket 101 transversely, and a rod is inserted in the pipe hole 103 105, the two ends of the rod 105 extend to the outside of the buoy 101 and then are equipped with nuts 166, the nuts 166 are screwed in and contact the buoy 101, and the outer walls of the rod 105 near both ends are A through hole 106 is processed, the through...

Embodiment 2

[0048] refer to Figure 7 As shown, a protective layer 110 is sandwiched between the buoy 101 and the shell 108; the main function of the protective layer 110 is to place the buoy to leak after being tiled. When we install the fixing device, the fixing device is If it is pierced into the shell, it may puncture the floating bucket when the force is excessive, but by setting a protective layer, the puncture can be effectively avoided; at the same time, the protective layer can also increase the rigidity of the product. The shell is soft and can absorb Collision force, the protective layer can increase the bending strength and reduce the chance of the buoy being damaged.

[0049] The protective layer 110 is made of stainless steel with a thickness of 0.25mm~0.55mm.

Embodiment 3

[0051] refer to Figure 8 and Figure 9 As shown, the fixing device 7 includes a cannula 701, one end of the cannula 701 is processed into a conical piercing end 711, and the bristles 4 are inserted into the cannula 701 and fixed by spot welding. The side of the housing 108 is axially provided with a first through hole 5, and a plurality of positioning grooves 6 corresponding to the first through holes 5 are annularly provided on the outer wall of the housing 108, and the positioning grooves 6 axially penetrate all The casing 108, the piercing end 711 pierces from the positioning groove 6, and pierces into the first through hole 5; the fixing device is easy to process, and it is easy to fit in when assembling. At first, the cannula can be preheated. The preheated cannula can be inserted into the shell more easily, and it will cause the heat fusion of the shell. When the heat-fused part of the shell is cooled again, it can be effectively Clamp and fix the cannula to prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com