Iron ore powder smelting cost measuring and calculating method

An iron ore powder and cost technology, which is applied in the field of iron ore powder smelting cost estimation, can solve the problems of inability to accurately evaluate the cost performance of iron ore powder, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

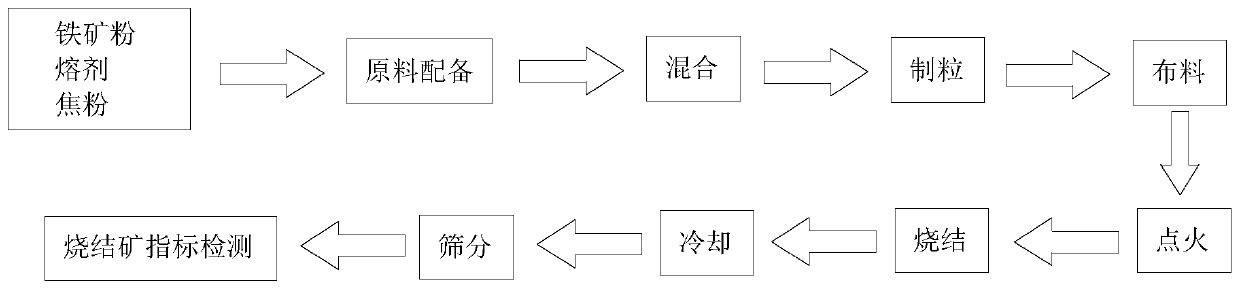

Method used

Image

Examples

Embodiment 1

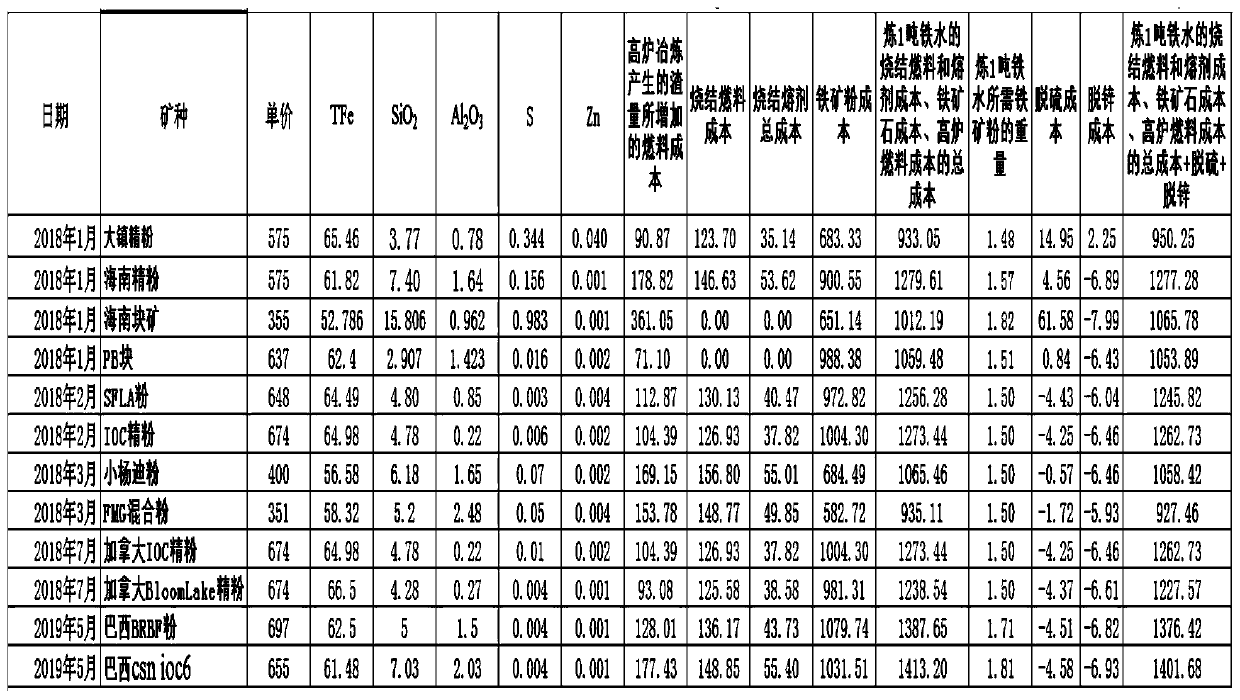

[0096] This embodiment provides a method for calculating the smelting cost of iron ore powder. Taking Brazilian BRBF powder as an example, calculate the cost required to smelt each ton of molten iron with this iron ore powder, and then compare it with the cost of other iron ore powders. Specifically include:

[0097] 1. The cost of iron ore powder, fuel and flux required to smelt each ton of molten iron with the iron ore powder

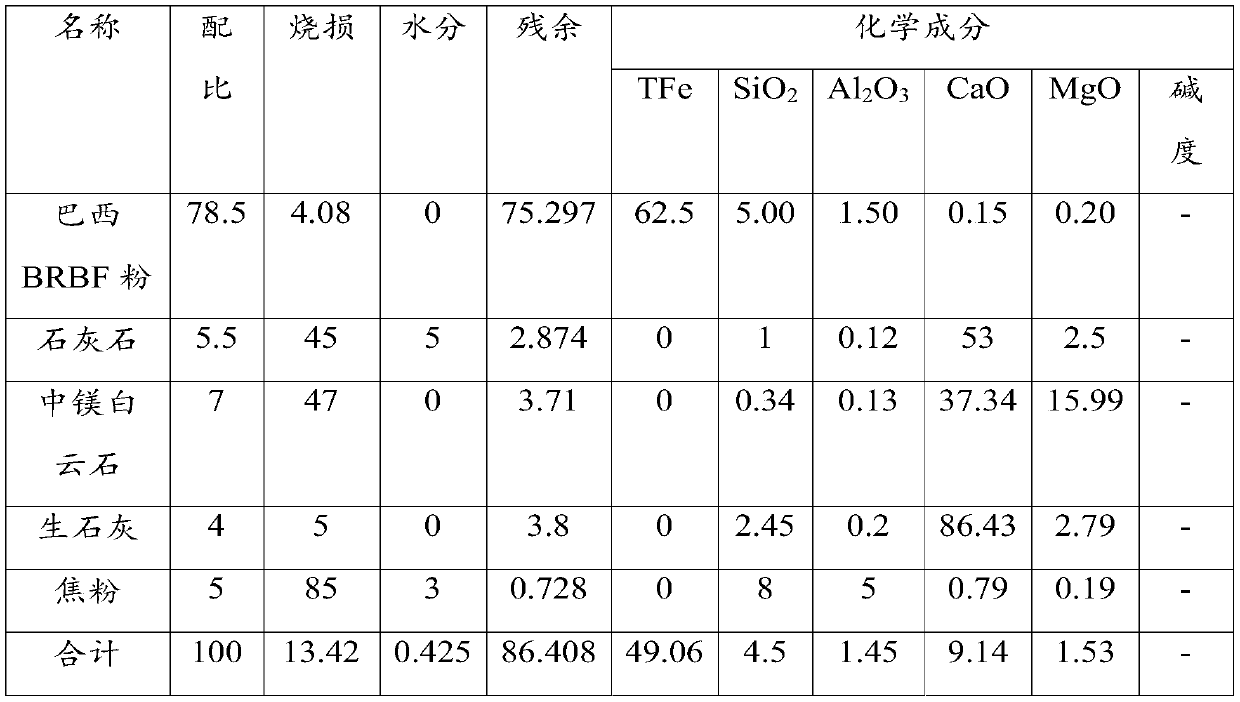

[0098] In terms of mass percentage, the iron ore powder is used alone for sintering, and its ratio is 78.5%. Flux and fuel are internally blended. The single caustic alkalinity of sinter is calculated as 2.0, and the ratio of fixed quicklime is 4%. The proportion of limestone and limestone makes the magnesium-aluminum ratio of sintered ore be 1, and the suitable coke powder proportion of sintered ore is 5%. The ratio of Brazilian BRBF powder single sintering sintering material is as follows:

[0099] Table 2 Ratio of Brazilian BRBF powder single-sin...

Embodiment 2

[0134] This example provides a method for calculating the cost of smelting iron ore powder. Taking Brazil csn ioc6 powder as an example, calculate the cost required to smelt each ton of molten iron with this iron ore powder, and then compare it with the cost of other iron ore powders . Specifically include:

[0135] 1. The cost of iron ore powder, fuel and flux required to smelt each ton of molten iron with the iron ore powder

[0136] Brazil csn ioc6 powder single sintering material ratio table is as follows:

[0137] Table 3 Ratio of single-sintered sintering materials of Brazil csn ioc6 powder

[0138]

[0139] The ratio, burning loss and moisture in Table 3 are based on the actual ratio and the performance parameters of raw materials. The composition of sinter is calculated from the chemical composition, moisture and burning loss of a single ore, fuel, and flux. Calculated according to Table 3:

[0140] X1 = total weight of iron contained in 100 kg of sintered mixtu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap