A Piezoelectric Ceramic Recycling Friction Self-excited Vibration Energy

A piezoelectric ceramic, self-excited vibration technology, applied in the components of brakes, energy-absorbing brakes, brake types, etc., can solve the problems of difficult, limited, and unreachable pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

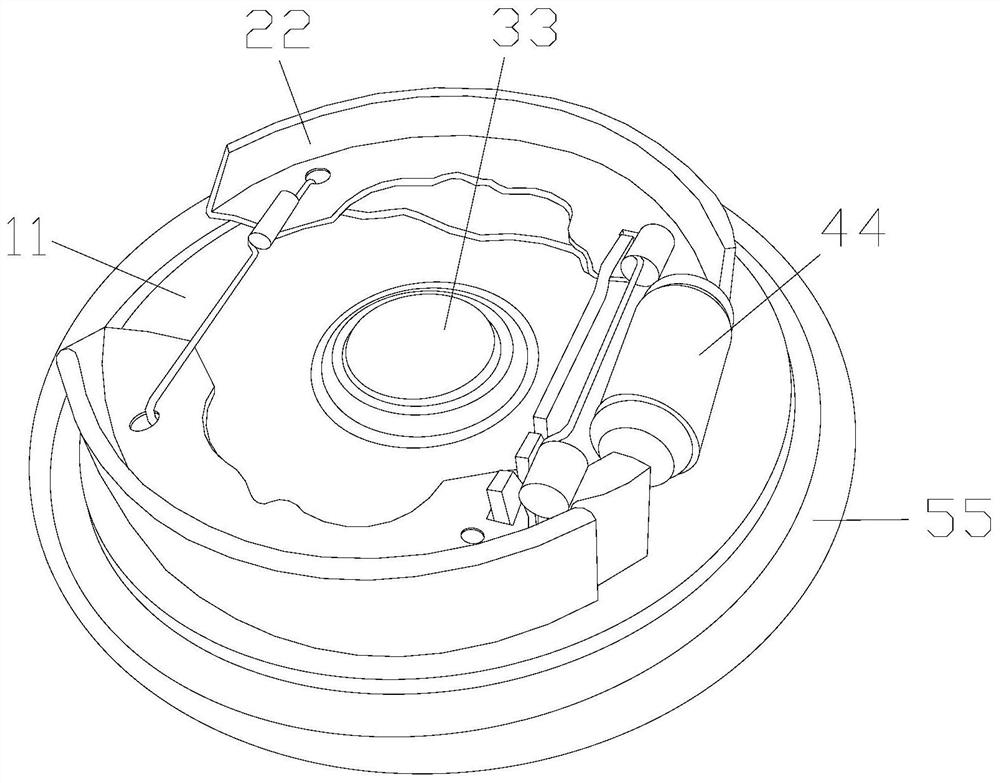

[0028] as attached figure 1 to attach Figure 7 Shown:

[0029] The present invention provides a piezoelectric ceramic for recovering friction self-excited vibration energy, the structure of which includes a brake base plate 11 , a brake shoe 22 , a piezoelectric ceramic ring 33 , a wheel cylinder 44 and a brake drum 55 .

[0030] The brake shoe 22 is mounted on the upper surface of the brake base plate 11, the piezoelectric ceramic ring 33 is embedded in the brake base plate 11, the wheel cylinder 44 is located on the outer surface of the brake base plate 11, and the brake base plate 11 is away from One end of the brake shoe 22 is connected to the brake drum 55 .

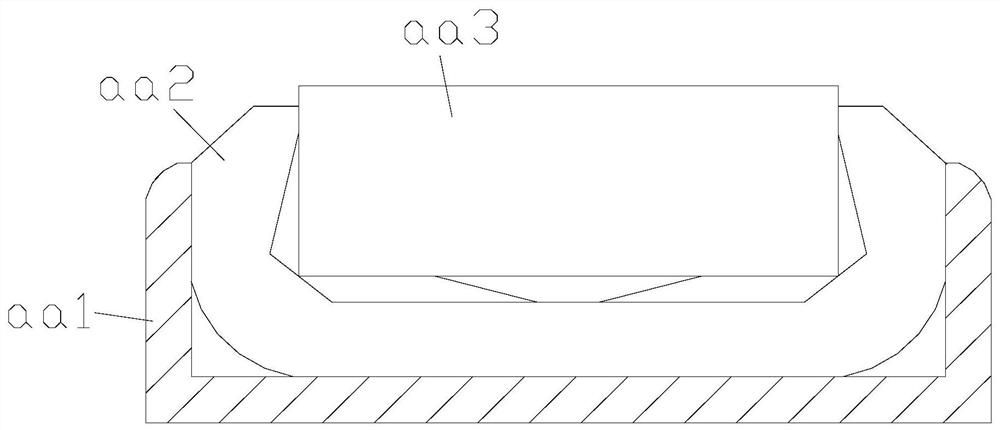

[0031] The piezoelectric ceramic ring 33 includes a device shell aa1, a balance groove aa2, and a piezoelectric ceramic body aa3. The balance groove aa2 is installed inside the device shell aa1. aa3 are connected.

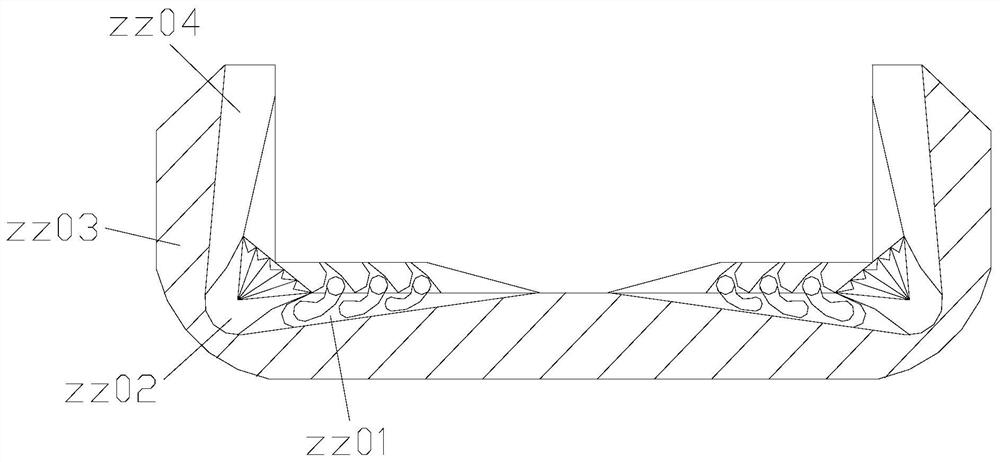

[0032] Wherein, the balance groove aa2 includes an inclined bottom zz01, an interval spread zz02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com