Solar Panel Defect Detection Method

A solar panel and defect detection technology, applied in image data processing, instruments, computing and other directions, can solve the problems of high detection environment requirements, reduce detection efficiency, low detection efficiency, etc., achieve low requirements for environmental lighting conditions, and improve detection efficiency. , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

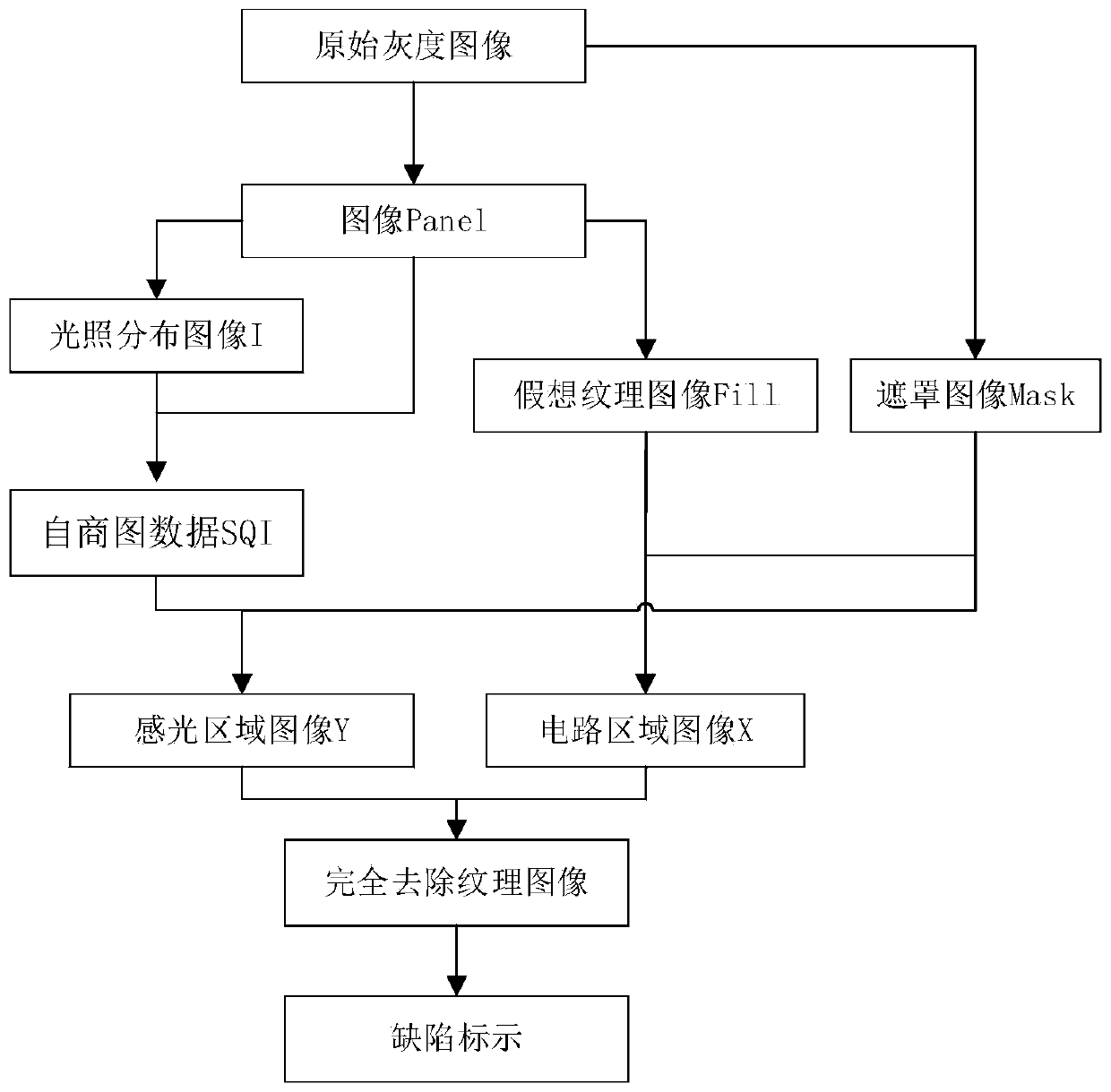

[0032] A solar cell panel defect detection method, the method comprising:

[0033] Step 1: Use an ordinary area array camera to obtain the original grayscale image of the solar panel, and use the morphological operator structure to perform a closed operation on the original grayscale image, remove the grid texture, and obtain the image Panel.

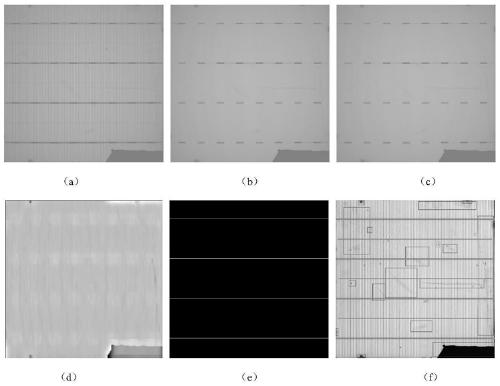

[0034] The present invention uses an ordinary area array camera to acquire the original grayscale image G(x, y) of the solar panel. figure 2 The image shown in (a) is the original grayscale image of the solar panel taken under a point light source. Considering that the surface texture of the circuit board is grid-like, which will interfere with subsequent processing, the grid-like texture should be removed. Use the morphological filtering method to remove the grid texture, with a directional morphological operator structure as follows: X-direction structural elements: Structural elements in the Y direction: Using K x The operator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com