A suspension structure with prestressed steel cables added to a steel truss

A prestressed steel and steel truss technology, applied in the field of suspension structures, can solve the problems of loss of bearing capacity, high sensitivity to external force resistance, low redundancy, etc., and achieve the effect of enhancing safety and saving construction measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

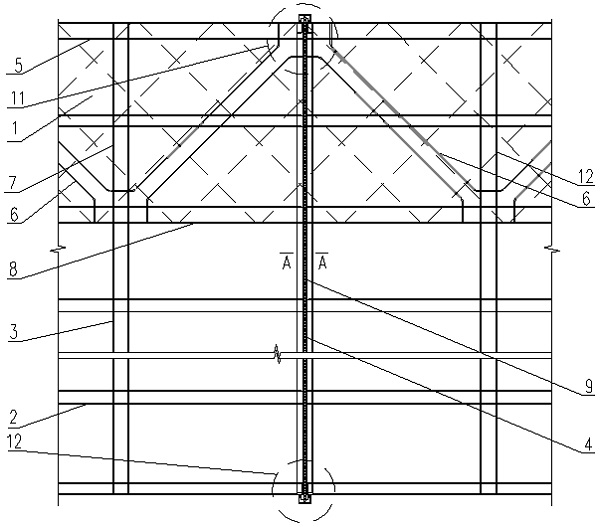

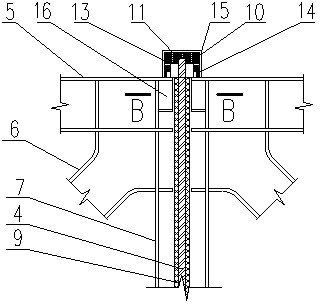

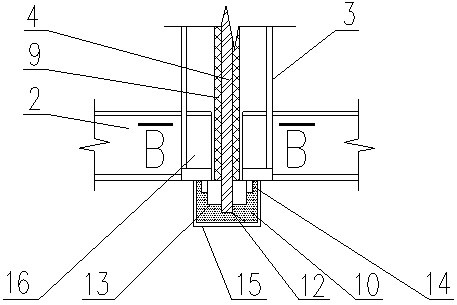

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] like figure 1 As shown, the present invention is a suspension structure in which prestressed steel cables are added in steel trusses, including steel trusses 1, steel frame beams 2, steel columns 3, and prestressed steel cables 4. The steel trusses 1 include The upper chord 5, the oblique rod 6, the vertical rod 7 and the lower chord 8, the vertical rod 7 runs through the upper chord 5 and the lower chord 8, and connects the upper chord 5 and the lower chord 8, and the lower end of the vertical rod 7 is connected to the lower hanging The steel columns 3 in the floor are aligned and connected up and down, the oblique rods 6 are obliquely connected between the upper chord 5 and the lower chord 8, and the vertical rod 7 and the steel column 3 at the mid-span of the steel truss 1 pass through the prestressed steel Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com