A wheel alignment rectification process

A wheel alignment and wheel technology, applied in the field of wheel alignment correction technology, can solve problems such as crane rail gnawing, and achieve the effects of high reliability, low cost and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

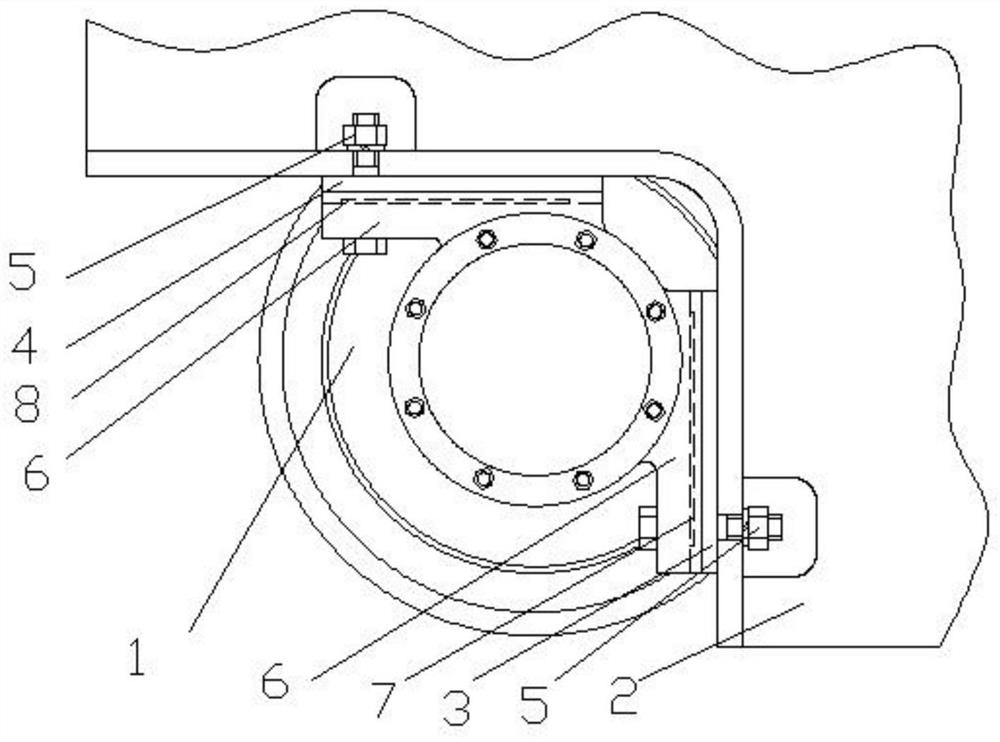

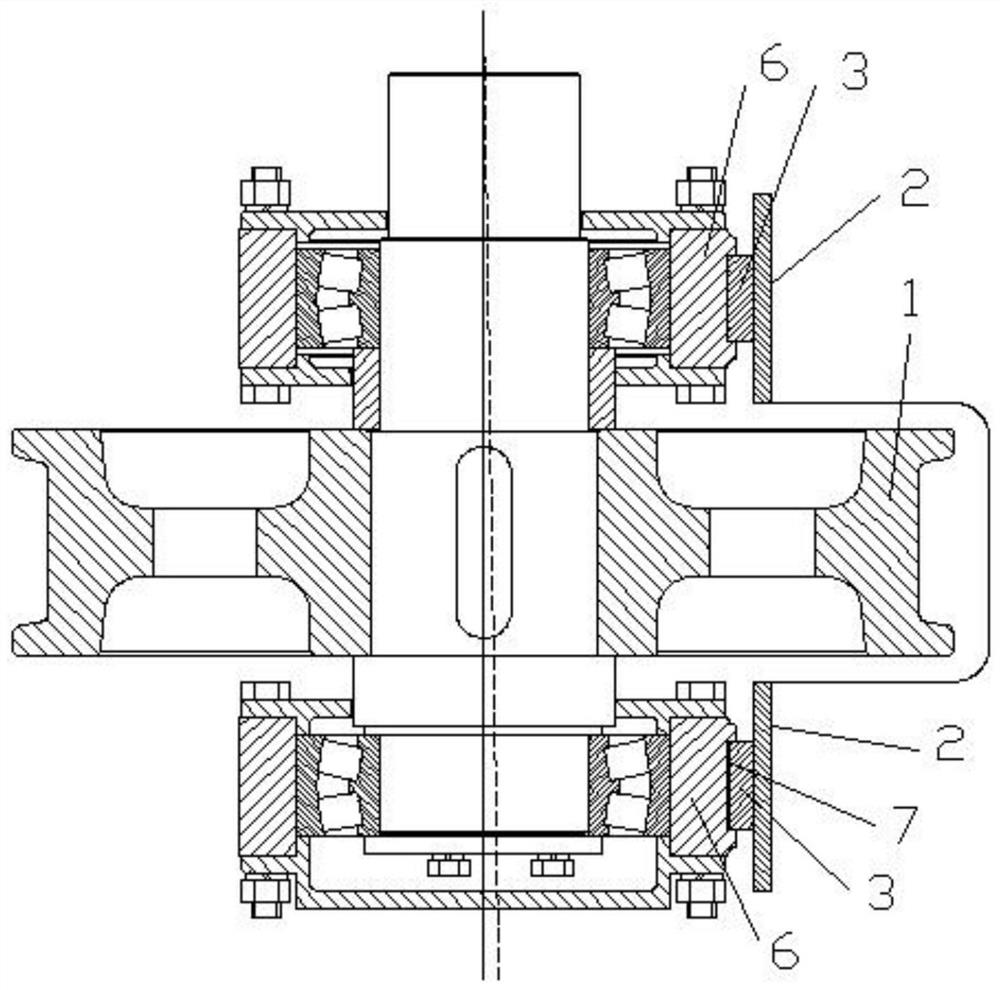

[0026] Such as Figure 1-5 As shown, a wheel alignment correction process includes wheel levelness detection and repair and wheel verticality detection and repair. The specific operation steps are as follows:

[0027] S1, the detection of wheel level and verticality: use the level detector to take the track center line as the reference line, detect the level value of each wheel 1 of a wheel group and record the detection point data, determine the deflection of each wheel 1 through the detection data, The detection of the levelness of the wheel 1 is mainly to measure the deflection of two symmetrical wheels A1 and B1, that is, to measure the deflection distance d1= 149.5mm, d2=151.5mm and d3=213.5, d4=212, the deflection is (d1-d2)=-2 and (d3-d4)=0.3 respectively;

[0028] Use a frame-type spirit level vertically close to the outer side of each wheel rim of the wheel group to detect the verticality one by one and record the data of the detection points, and determine the incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com