High-speed magnetic levitation turnout floating type supporting driving device and driving method

A driving device, floating technology, applied in electrical equipment, transportation and packaging, railway car body parts for manipulating turnouts or circuit breakers, etc. The effect of reducing manufacturing difficulty and ensuring uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

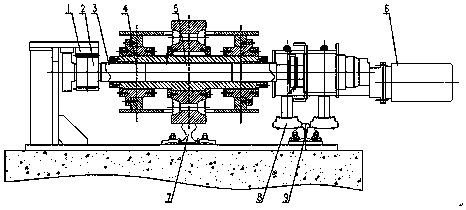

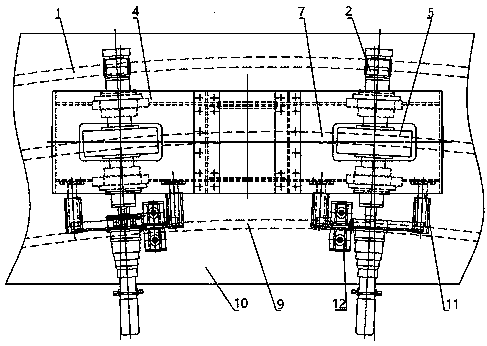

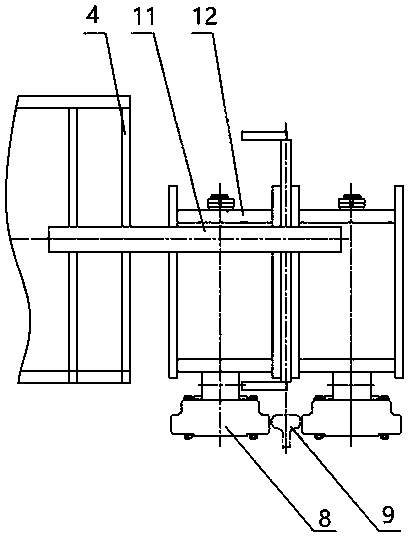

[0022] Embodiment 1: with reference to attached Figure 1-3 . A high-speed maglev turnout floating support driving device, which consists of a driving rack 1, a driving gear 2, a driving shaft 3, a trolley frame 4, a trolley wheel 5, a driving motor 6, a running rail 7, a guide wheel 8, a guide rail 9, In this structure, racks 1, running rails 7, and guide rails 9 are arranged on the basic bottom plate 10, and they are all arranged in a concentric circle in the layout form; the trolley wheels 5 and the trolley frame 4 are axially fixed together , the trolley wheel 5 can only realize rotation relative to the trolley frame 4; the drive shaft 3 penetrates the trolley frame 4 and the trolley wheel 5 to realize rotary motion, and the two sides of the drive shaft 3 are respectively provided with torsion sliding rods 11 and one end of the torsion sliding rod 11 Connected with the trolley frame 4, the other end of the torsion sliding rod 11 is slidably matched with the connecting rod...

Embodiment 2

[0030]Embodiment 2: On the basis of Embodiment 1, a driving method for a high-speed maglev turnout floating support driving device, the driving motor 6 drives the driving gear 2 to rotate through the driving shaft 3, and the driving gear 2 is connected to the base plate 10 installed on the base The drive rack 1 meshes to drive the trolley frame 4 to move, thereby dragging the turnout beam installed on the trolley frame 4 (the turnout beam is installed in the middle and upper part of the trolley frame, and is connected to the trolley frame by bolts, and the turnout beam is not included in this In the system) move to realize the switch, because the turnout beam is a flexible beam body and the influence of the turnout timing sequence, the track of the platform wheel 5 is an irregular curve and the track is not unique during the switch process, and a circular curve is fitted The shape of the running rail 7 is to meet the actual walking of the trolley. During the movement, it is aff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com