Valve base online replacing ball valve

A technology of valve seat and ball valve, which is applied in the field of improvement and invention of ball valves, and can solve problems such as easy wear of the valve seat on the outlet side, loss of manpower and material resources, and inability to perform online replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

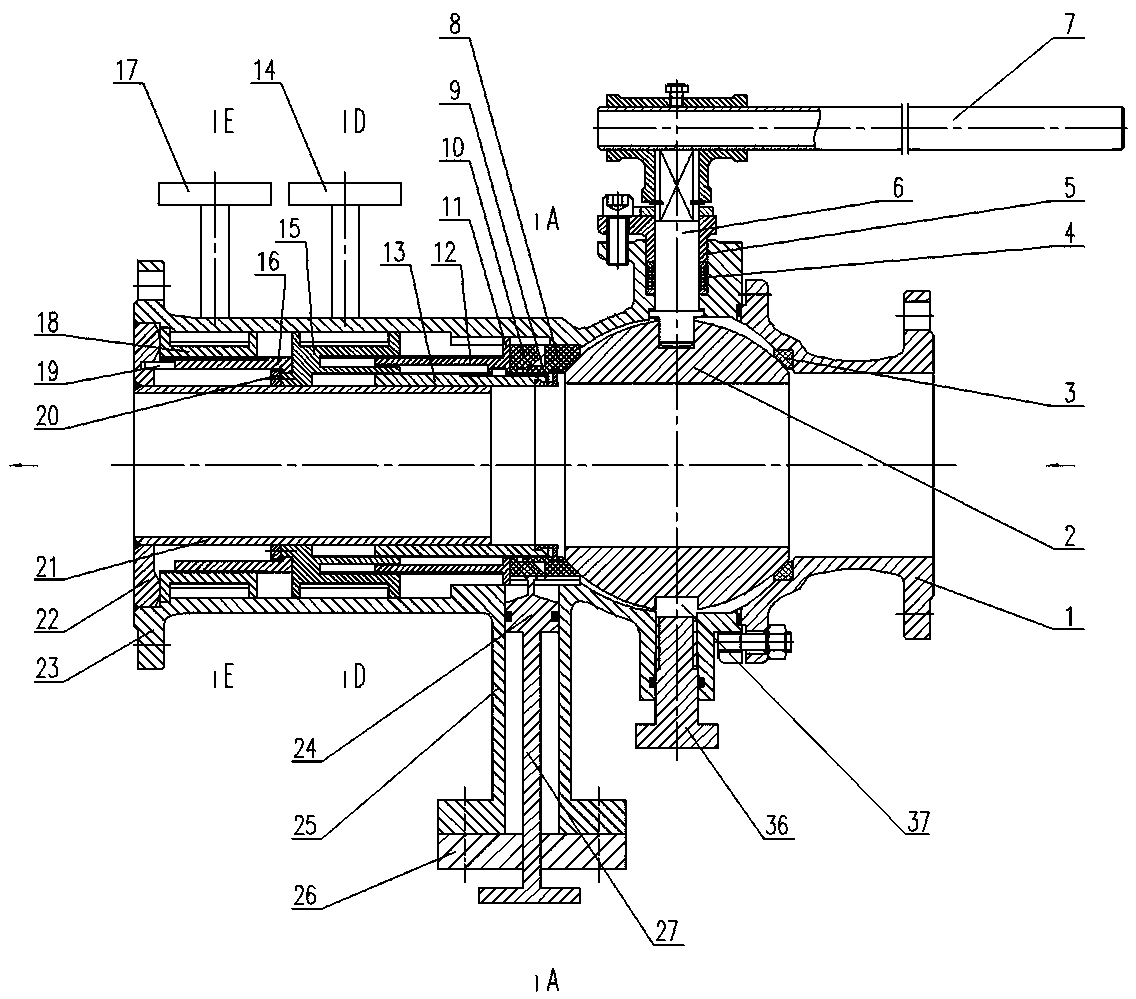

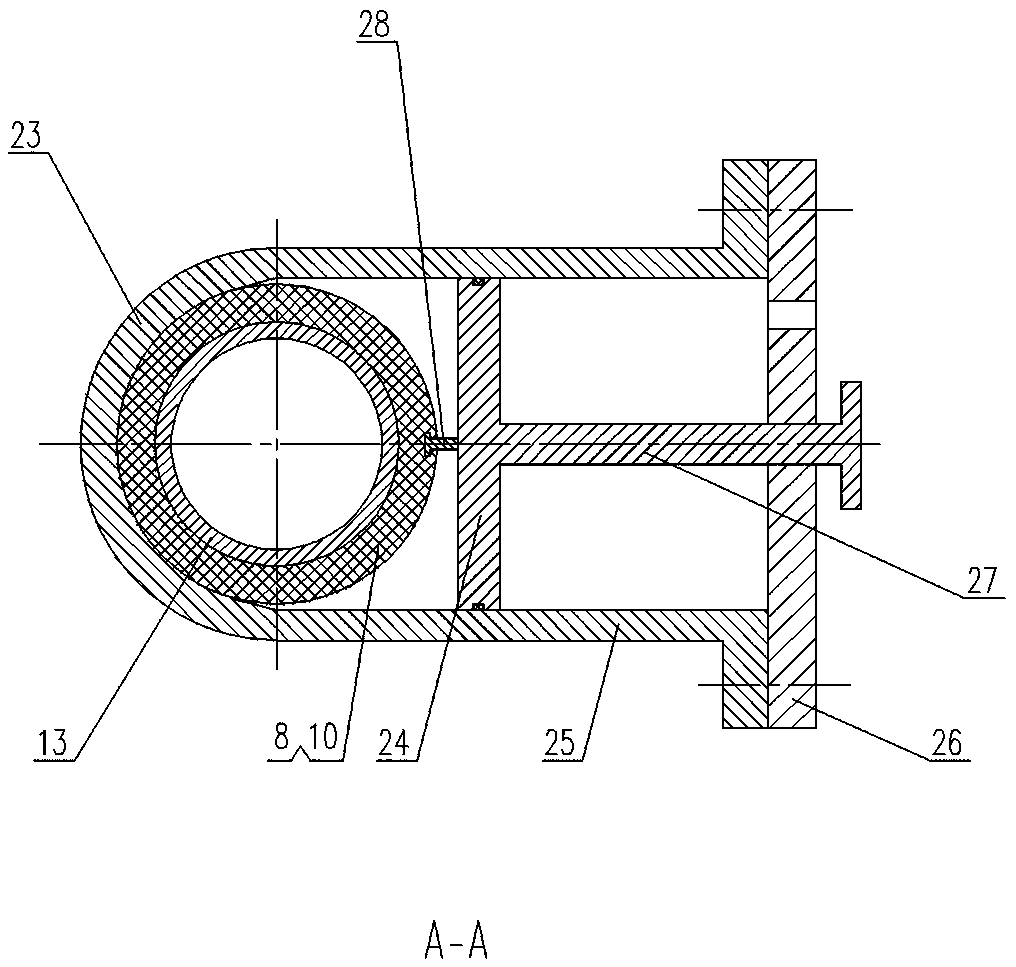

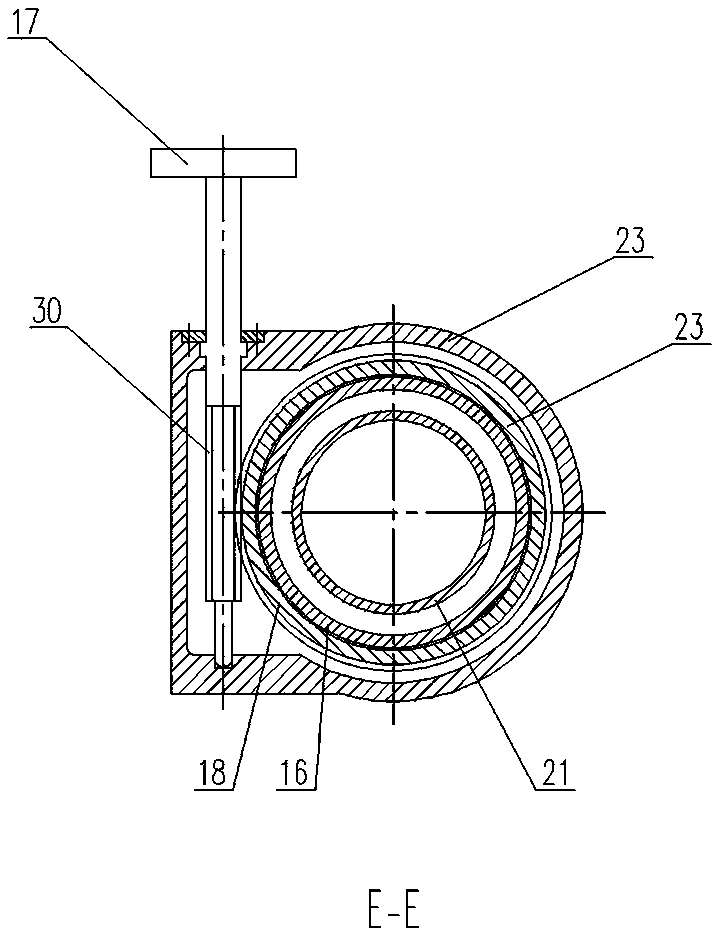

[0020] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The online seat replacement ball valve includes a left valve body 23 connected with a right valve body 1, a ball 2 is arranged in the right valve body 1, a left valve seat 8 is arranged in the corresponding left valve body 23, and a right valve body 1 There is a right valve seat 3 inside, and the left valve seat 8 and the right valve seat 3 are respectively sealed and matched with the ball 2; Connected with a wrench 7, the lower end of the right valve body 1 can move up and down and is provided with a positioning rod 36, and the lower end of the corresponding sphere 2 is provided with a positioning hole 37, and the positioning rod 36 is matched with the positioning hole 37; An inner bushing 21 is arranged in the channel, and the left end of the inner bushing 21 is fixed in the left valve body 23 by an outer pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com