An anti-sloshing liquid storage system with a self-cleaning porous medium layer

A porous medium layer and self-cleaning technology, applied in packaging, large containers, transportation and packaging, etc., can solve problems such as clogging of porous medium lumen, decline of sway reduction effect, reduction of wave impact force on the wall of liquid storage tank, etc., to achieve guarantee Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

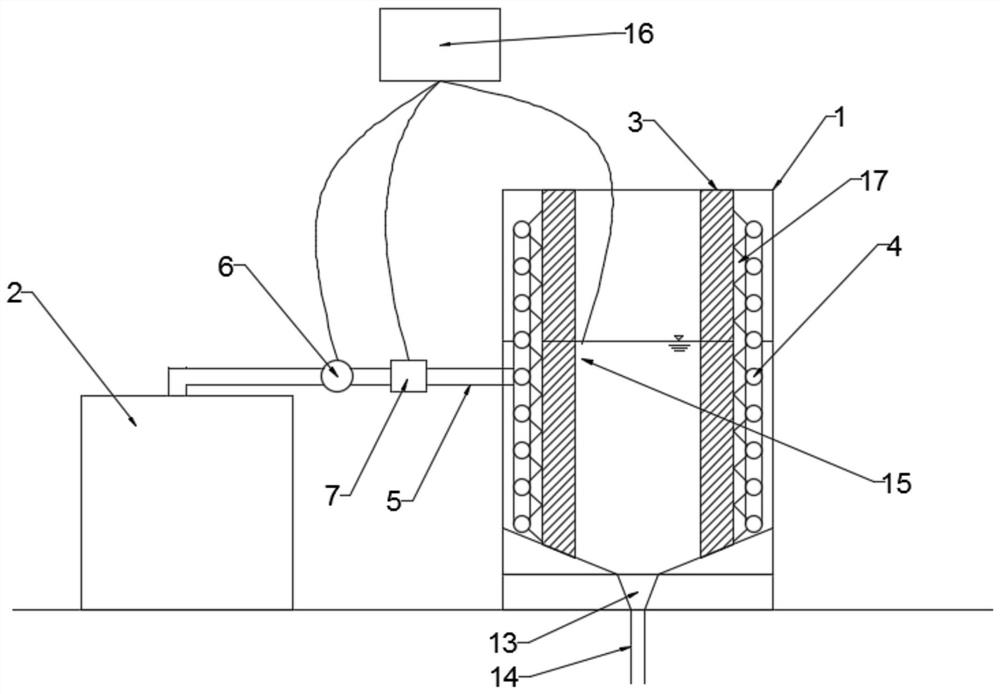

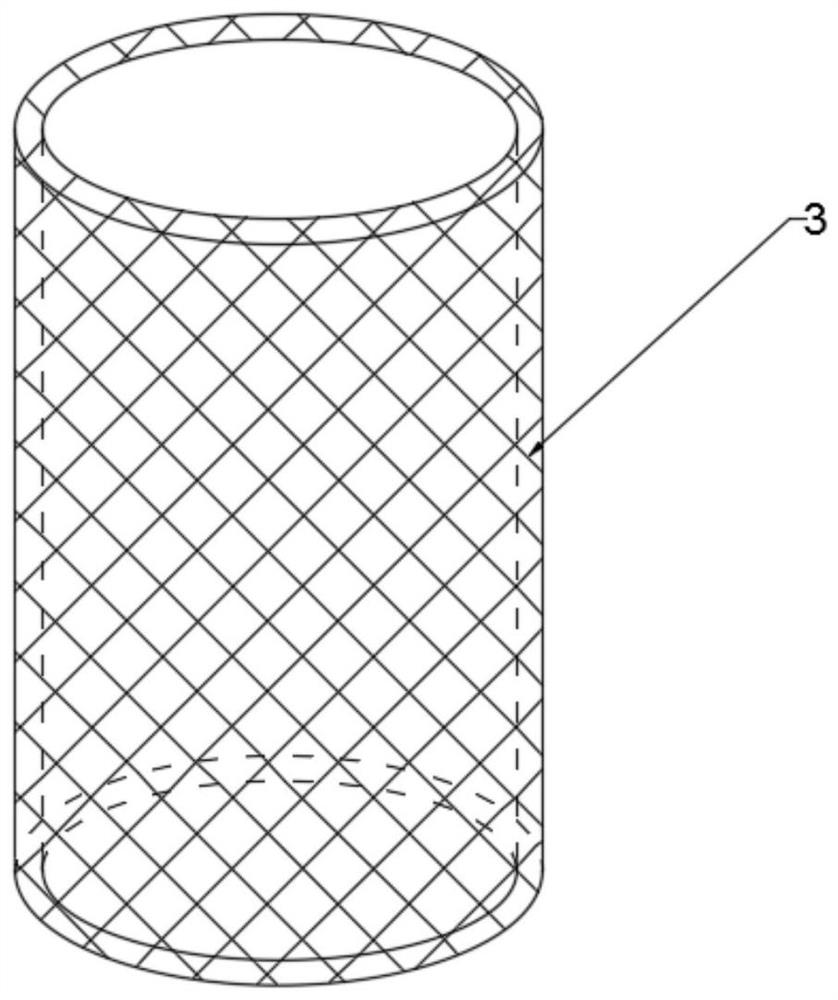

[0037] like Figure 1-6 As shown, the anti-sloshing liquid storage system containing the self-cleaning porous medium layer provided in this embodiment includes a liquid storage tank 1 and an air storage tank 2, and a porous medium layer 3 is arranged in the liquid storage tank 1, and the porous medium The exoskeleton of layer 3 is bent to form a cylindrical steel cage structure through steel bars, and the porous medium layer 3 is filled with hollow metal aluminum balls; the bottom of the porous medium layer 3 is connected to the funnel-shaped bottom of the liquid storage tank 1 The inclined surface is connected, and the top of the porous medium layer 3 is connected to the top of the liquid storage tank 1; the thickness of the porous medium layer is 1 / 5 of the radius of the liquid storage tank.

[0038] A tank washing device is provided between the inner wall of the liquid storage tank 1 and the porous medium layer 3, and the tank washing device includes an air intake mechanism...

Embodiment 2

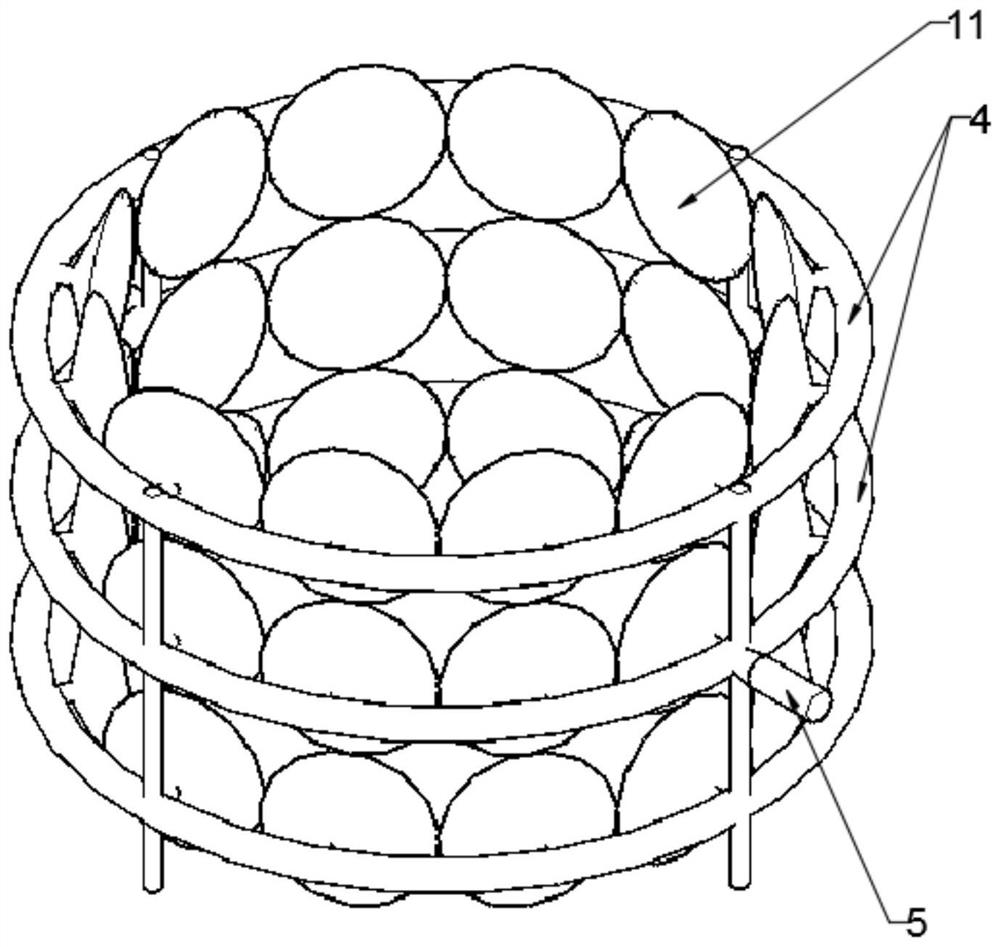

[0043] like Figure 7 , 8 As shown, the anti-sloshing liquid storage system provided in this embodiment containing a self-cleaning porous medium layer is different from that of Embodiment 1 in that: the bell mouths 11 of the two adjacent blowing mechanisms on the same annular pipe 4 are large mouth ends The setting of tangent to the plane where it is located; for example Figure 8 As shown, the bell mouths 11 of the air blowing mechanisms of the two adjacent annular ducts 4 are staggered and circumscribed, that is, any one of the bell mouths 11 of the lower layer is just at the same time as the two adjacent bell mouths of the upper layer. 11 circumcision. Each annular duct 4 of the air intake mechanism is provided with two air intake pipes 5, and the two air intake pipes 5 of each annular duct 4 are arranged symmetrically. The number of the gas storage tanks 2 is 2, and the air intake pipes 5 on the same side of all the annular pipes 4 are connected to one air storage tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com