Pilot change-over valve with position detoction function

A reversing valve, pilot-operated technology, applied in valve devices, valve details, fluid pressure actuators, etc., can solve problems such as being easily affected by external magnetic fields, magnetic sensor malfunctions, and reliability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

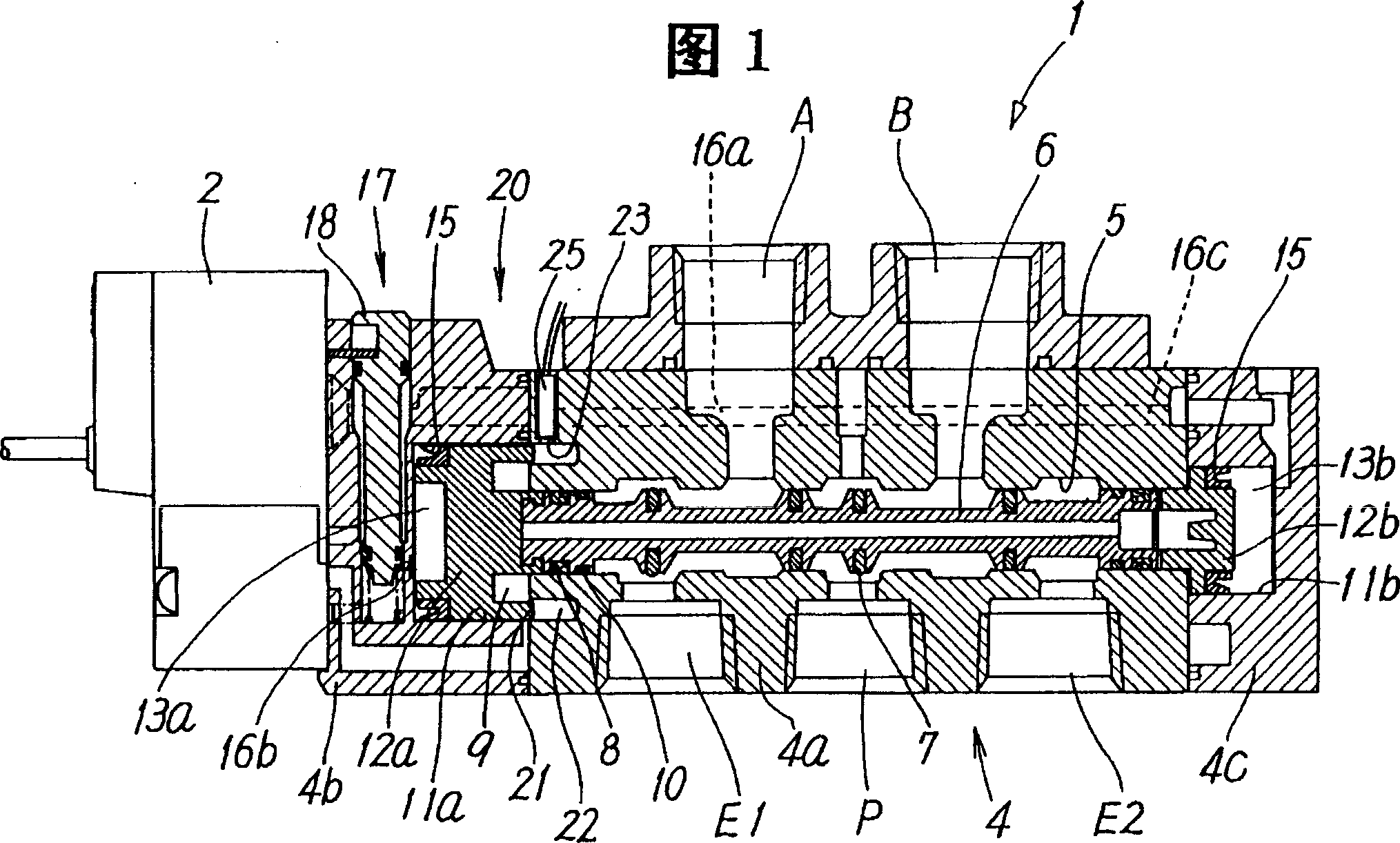

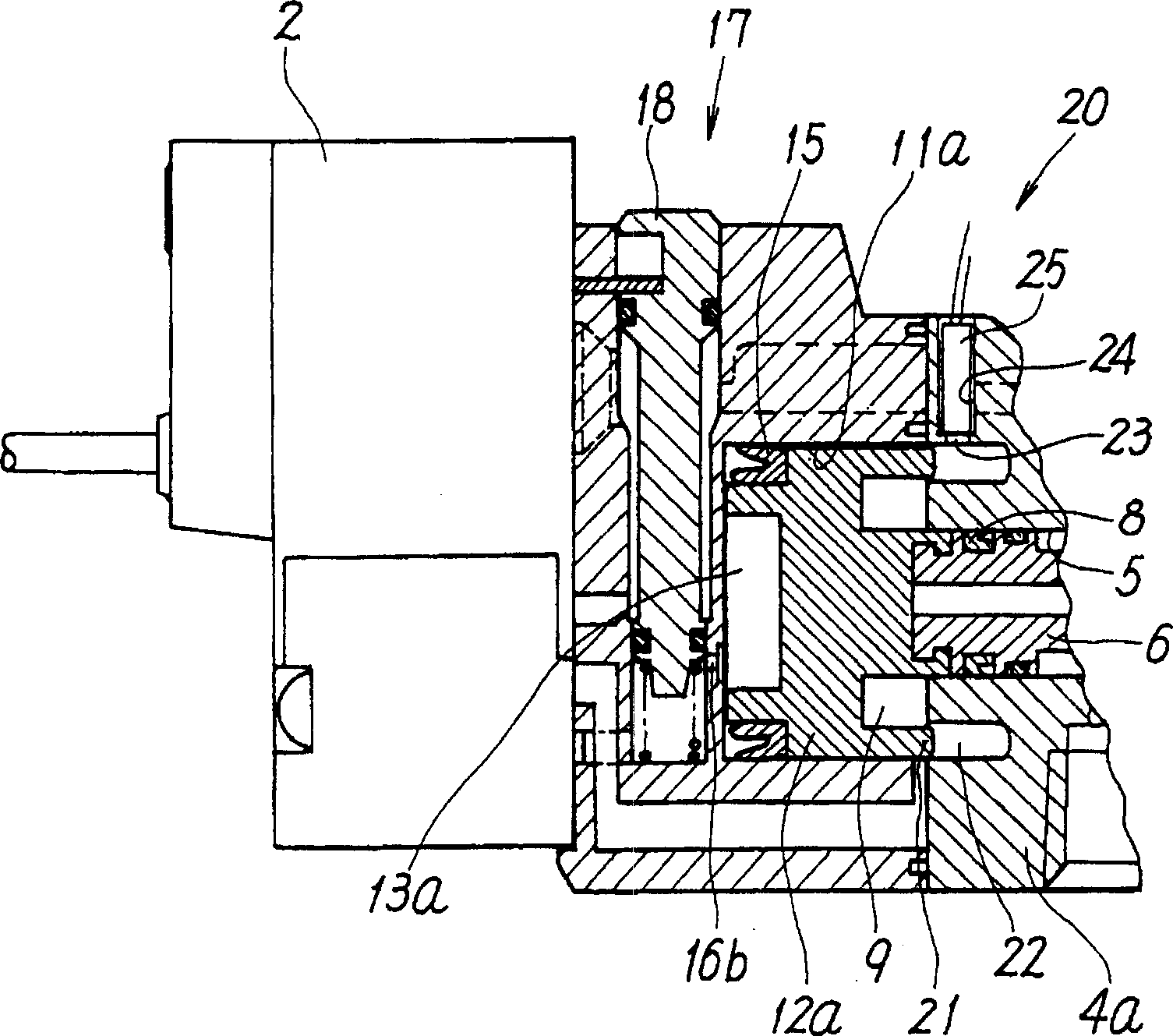

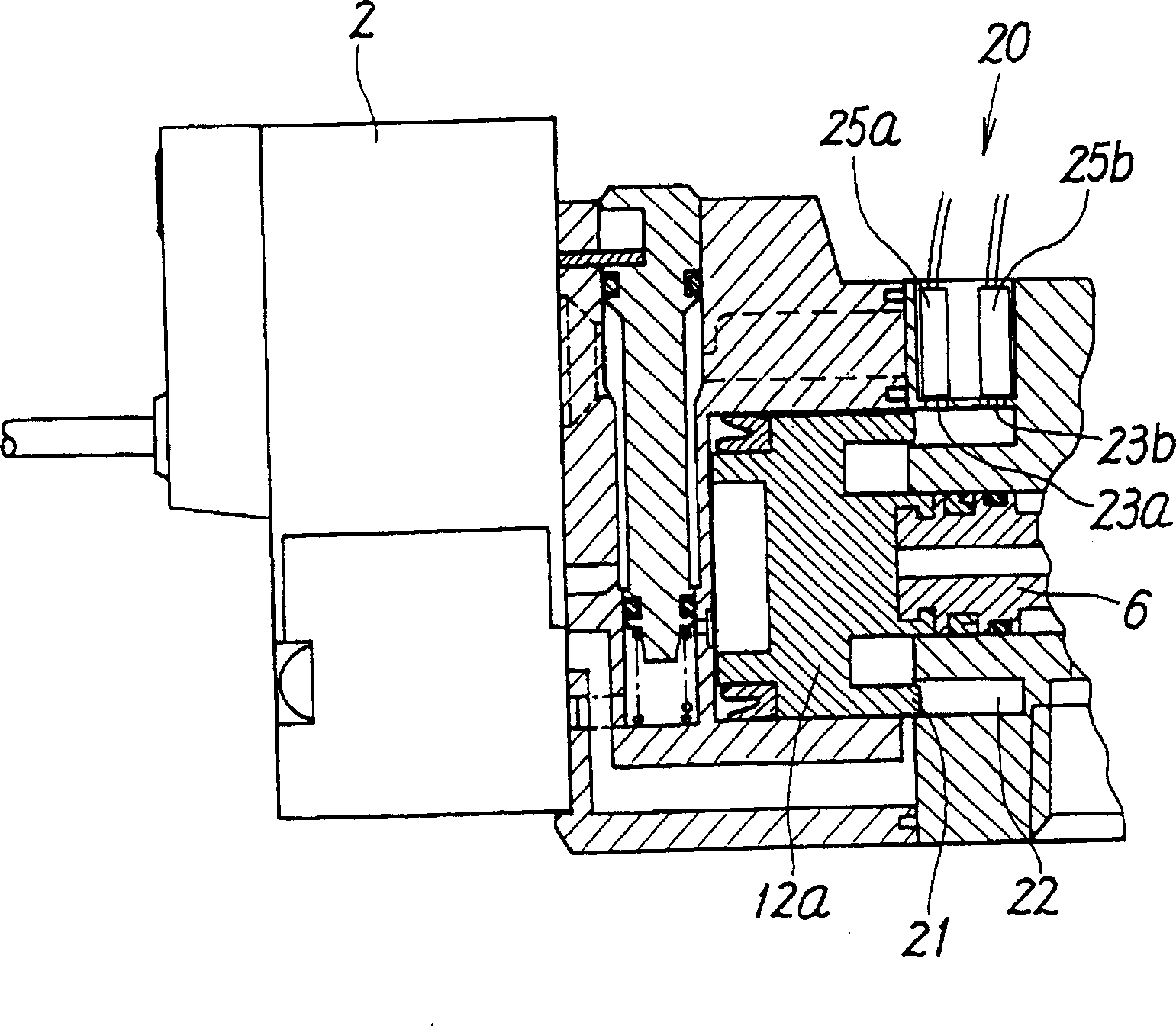

[0019] FIG. 1 shows the first embodiment of the reversing valve of the present invention. The reversing valve illustrated here is a single pilot reversing valve in which a main valve 1 is switched by a pilot valve 2 .

[0020] The above-mentioned main valve 1 has a configuration as a 5-port valve and includes a valve body 4 . This valve body 4 consists of a cube-shaped first member 4a, a second member 4b that is connected to one end and serves as a connector for installing the pilot valve 2, and a second member 4b that is connected to the other end and functions as an end cap. The third member 4c is composed.

[0021] On the upper and lower surface of the first member 4a, a supply port P and two discharge ports E1, E2 are provided, and two output ports A, B are provided on the other surface. Inside the first member 4a, A valve hole 5 is provided in which each of these orifices is opened side by side in the axial direction, and a valve element 6 serving as a valve member for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com