Printer cleaning system

A cleaning system and printer technology, applied in the field of cleaning systems, can solve the problems of high cost, pollution, large movement error, etc., and achieve the effect of effective cleaning effect, prevention and control of pollution problems, and small movement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention can have various changes in different aspects without departing from the scope of the present invention, and the descriptions and illustrations therein are used as illustrations in nature rather than limiting the present invention .

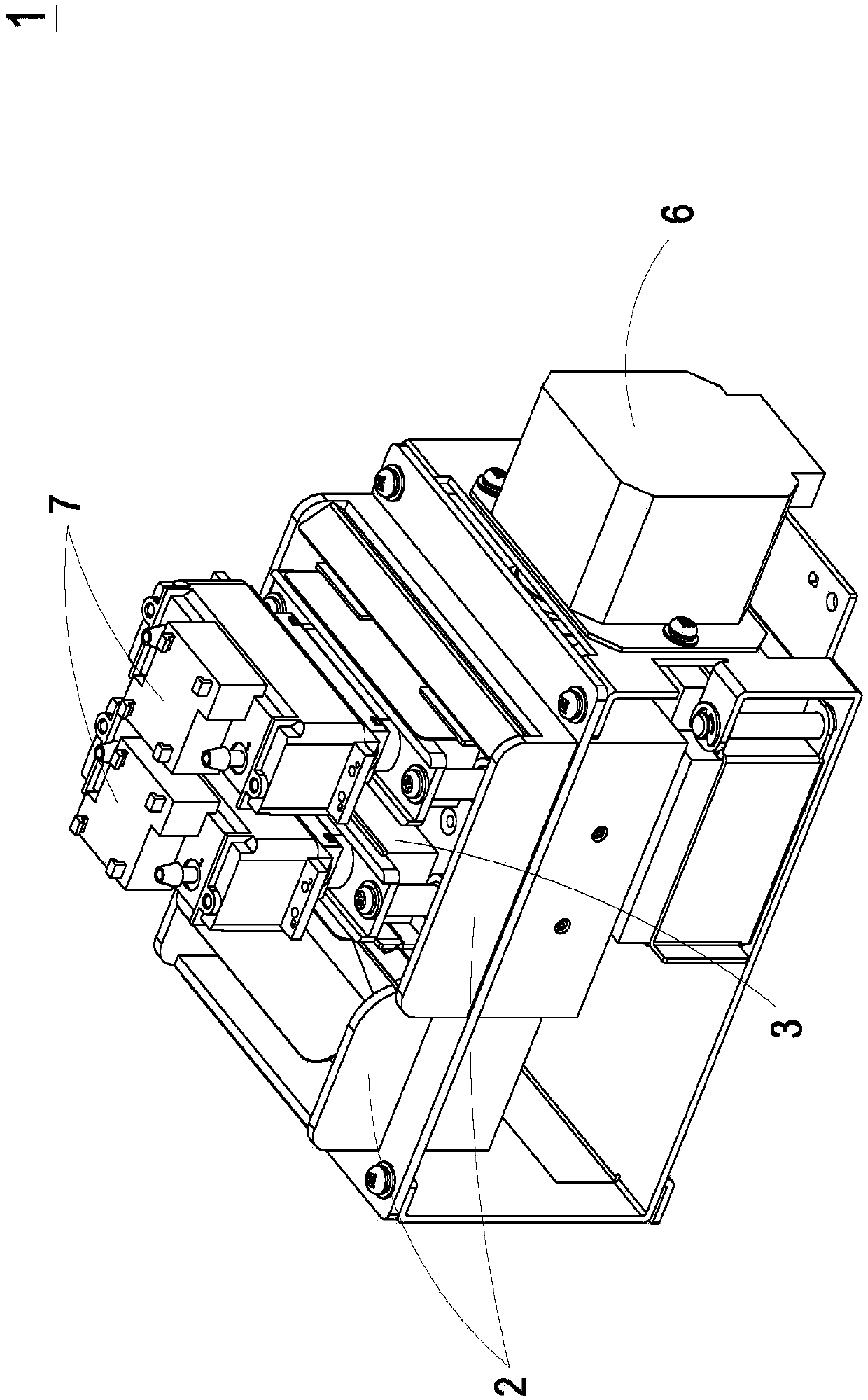

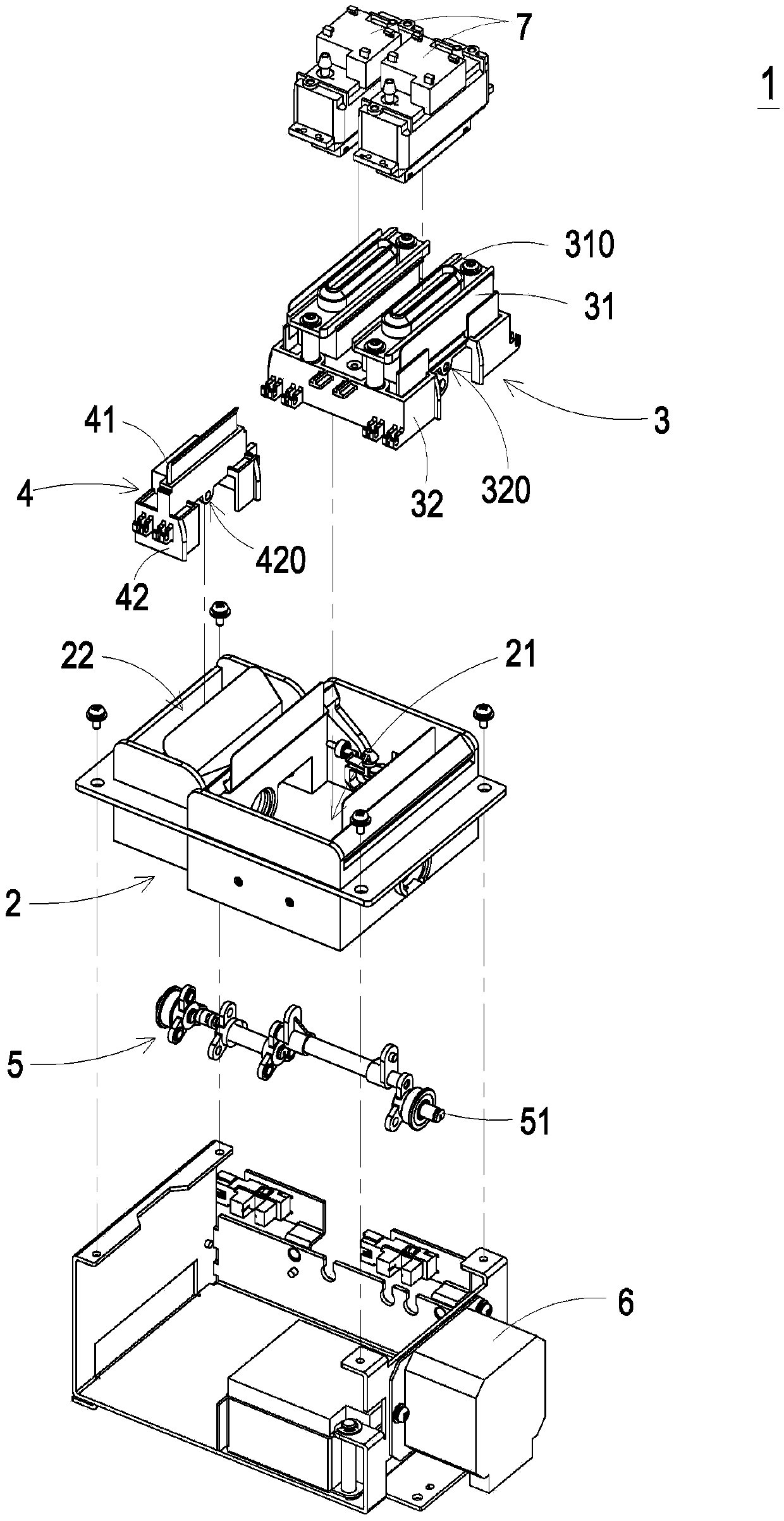

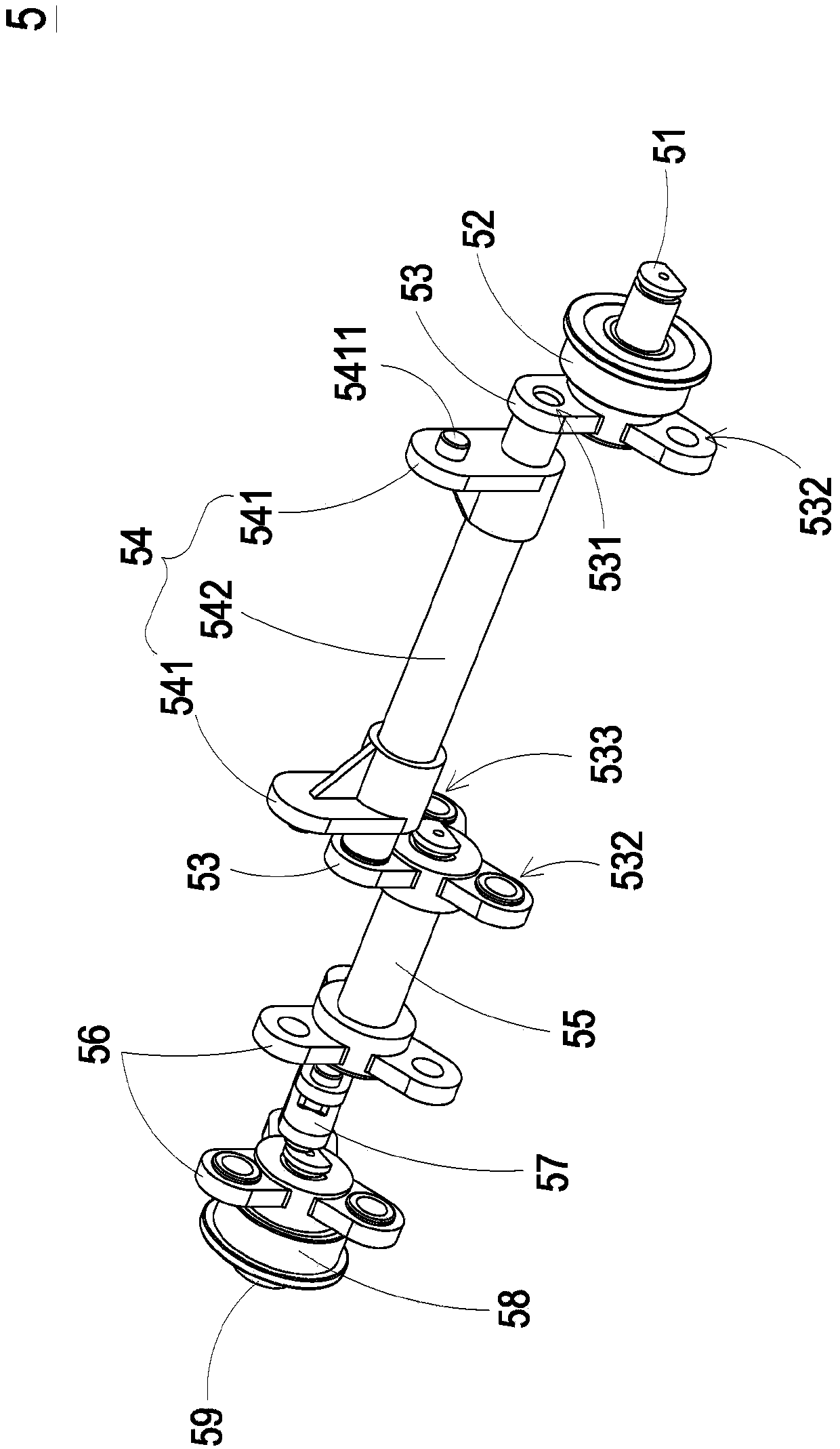

[0087] see Figure 1A and Figure 1B ,in Figure 1A A structural perspective view showing a printer cleaning system in a preferred embodiment of the present invention, and Figure 1B show Figure 1A A schematic diagram of the exploded structure of the printer cleaning system shown. Such as Figure 1A and Figure 1B As shown, the printer cleaning system 1 of the preferred embodiment of the present invention includes a cleaning base 2 , an ink stack assembly 3 , a scraper assembly 4 , a transmission device 5 and a driving devic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap