Dust collection device for spinner

The technology of a vacuum device and a vacuum tube is applied in the direction of textiles and paper making to achieve the effects of easy movement, convenient use and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

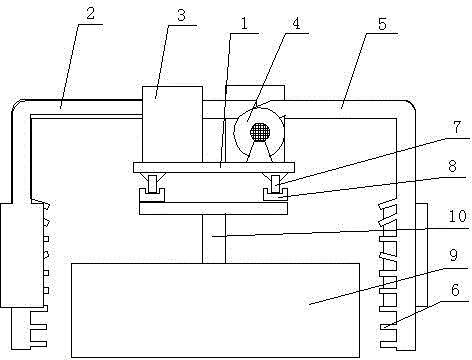

[0015] Such as figure 1 As shown, this embodiment provides a dust collection device for a yarn output machine, including a blower dust suction mechanism, a base 1 for fixing the blower dust suction mechanism, and a traveling mechanism for moving the blower dust suction mechanism , the blowing and dust suction mechanism includes a dust suction pipe 2, a dust collection box 3, a fan 4, a blowing pipe 5 and several blowing nozzles 6 connected to the blowing pipe 5, and the dust collection box 3 is fixed on the base 1 , the dust suction pipe 2 is connected to the inlet of the dust collection box 3, the outlet of the dust collection box 3 is connected to the air inlet of the fan 4, and the air outlet of the fan 4 is connected to one end of the blowing pipe 5, The other end of described blowing pipe 5 is provided with some blowing nozzles 6, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap