Food molding method

A food molding and food technology, applied in food science, baking, dough processing, etc., can solve the problem that dumplings are not easy to be taken out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A food forming method, comprising the steps of:

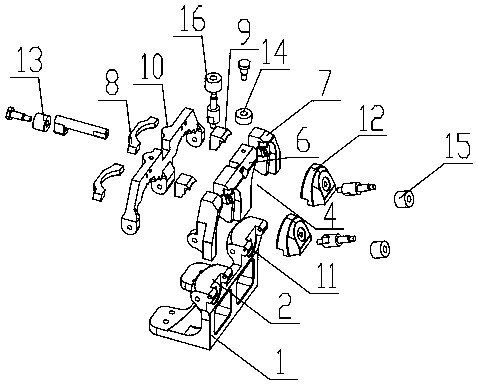

[0046] Step 1: The dough and stuffing fall on the dough forming block 3, and fall into the forming cavity 4 of the skin forming block 3, and the dough and stuffing are formed on the inner side of the dough forming block, the support surface 2 and the wheel base 12 material to provide support;

[0047] Step 2: the wheel base 12 moves towards the direction of the dough forming block 3, squeezes one side of the dough, the skin forming block 3 moves towards the direction of the wheel base 12, and cooperates with the wheel base 12 to seal and press the edges around the dough;

[0048] Step 3: After the pressing is completed, the wheel seat 12 moves in reverse, and the fifth forming block 9 is separated from the skin forming block 3, so that the top of the forming cavity 4 forms an open channel 5, and the top of the forming cavity 4 passes through the open channel 5 connected with the outside;

[0049] Step 4: The formed foo...

Embodiment 2

[0051] Step 1 is: bonding the skinning forming block 3 and the fourth forming block 10, the fifth forming block 9 is located in the open channel 5 of the skinning forming block 3, and the skinning forming block 3 and the fourth forming block 10 are facing the forming seat 1 is inclined on one side, and the wheel seat 12 is inclined towards the other side of the forming seat 1, and a support surface 2 is formed on the inner side of the forming dough piece, the supporting surface 2 and the wheel seat 12 for supporting the dough and the stuffing.

[0052] The second step is: the skin-joining forming block 3 and the fourth forming block 10 are kept in contact, and both are rotated toward the wheel base 12 at the same time, the wheel base 12 is rotated towards the skin-joining forming plate, and the dough is folded and pressed onto the wheel base Between 12 and the forming block 3 of the skin, after the edge of the dough is pressed against by the pressing edge of the inner cavity of...

Embodiment 3

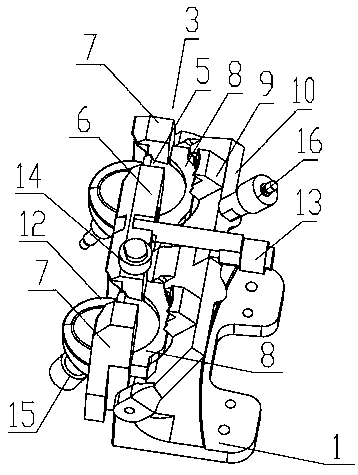

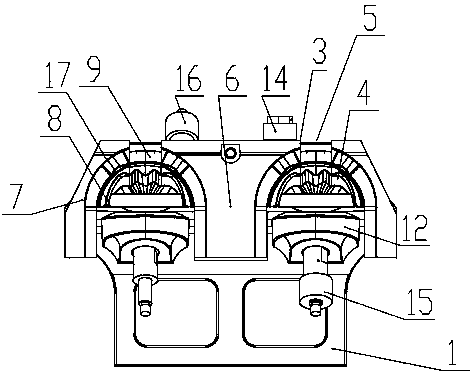

[0056] On the basis of Embodiment 1 or 2, the equipment used in this method is a new type of food forming mold, including a forming seat 1, and one side of the forming seat 1 is provided with a supporting surface 2 and a rotating shaft that can be rotated around the forming seat 1 11 Rotating skin grafting forming block 3, forming cavity 4 between the edge of the inner opening of the skin grafting forming block 3 and the support surface 2, the top of the forming cavity 4 is provided with an external vertical and horizontal direction. The open channel 5. The effect of forming cavity 4 is to be used for food to carry out molding, and food is accommodated in forming cavity 4. The effect of connecting skin molding block 3 is to be used for catching dough and auxiliary food molding. The open channel 5 vertically penetrates means that the edge of the forming cavity 4 can communicate upwardly with the external space through the open channel 5, and the horizontally penetrated means t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com