Novel pre-twisted support type T-shaped wire clamp capable of preventing wire breakage

An anti-break, supporting technology, applied in electrical components, circuits, welding/welding connections, etc., can solve problems such as stress concentration of hydraulic T-clamps, enhance overall strength and diversion performance, and solve stress concentration. Phenomenon, the effect of solving the problem of stagnant water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

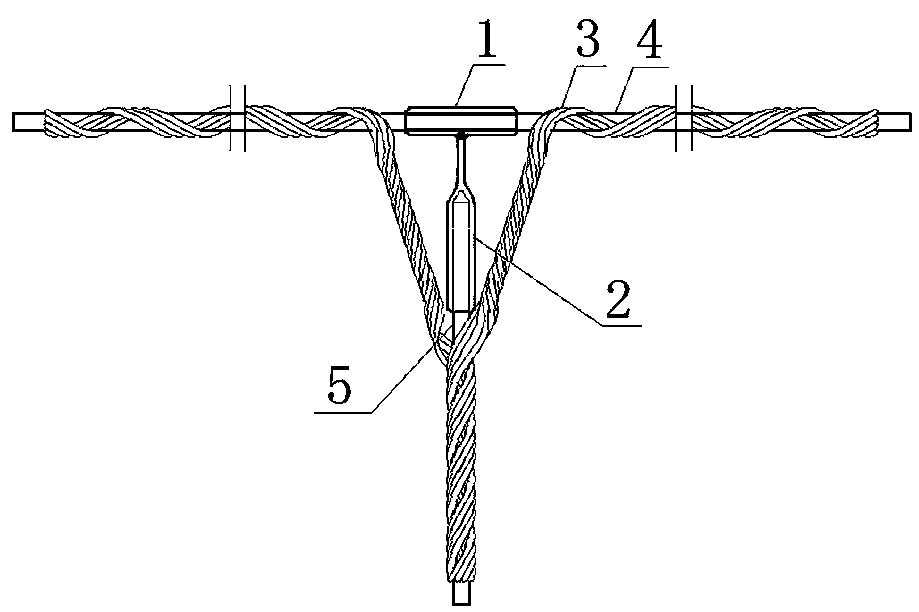

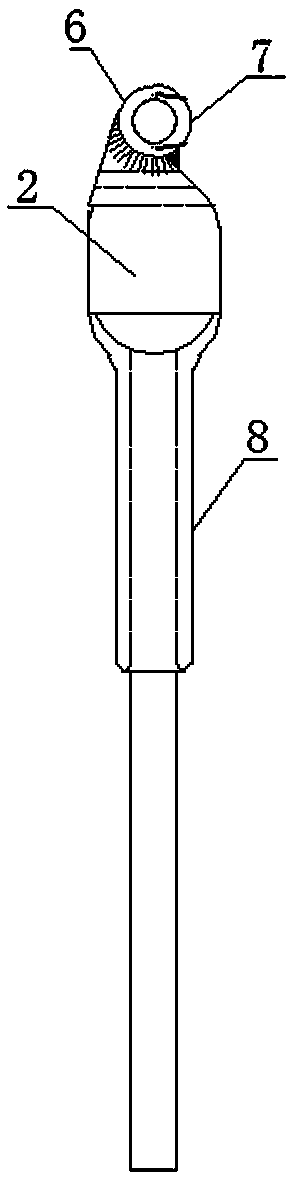

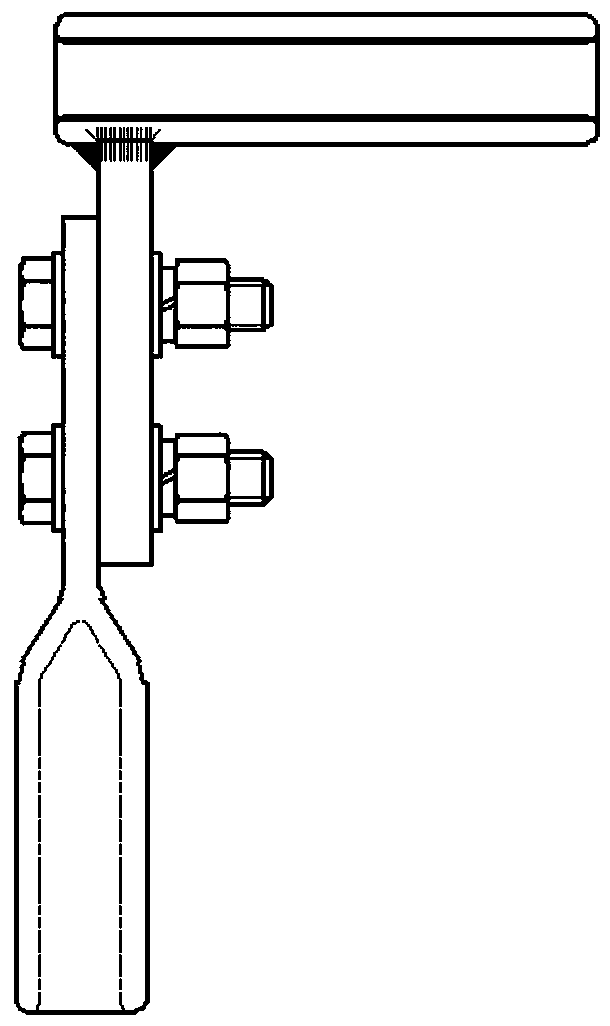

[0022] Such as figure 1 and figure 2 As shown, a new anti-breakage pre-twisted support type T-shaped clamp of the present invention includes a clamp main body 1, a drain plate 2 and two sets of supporting twisted wires 3, the clamp main body 1 is sleeved on a conductor 4 and Both ends of the clamp main body 1 are tightly pressed on the outside of the conductor 4, one end of the drain plate 2 is fixed in the middle of the clamp main body 1, and one end of the two sets of supporting twisted wires 3 is respectively wound around the conductors outside the two ends of the clamp main body 1 4, the other ends of the two groups of supporting twisted wires 3 are all wound on the lower end of the drainage plate 2 and the drainage wire 5.

[0023] The main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com