Novel pre-twisted reinforced T-shaped wire clamp capable of preventing wire breakage

It is a pre-twisted and reinforced technology for preventing wire breakage. It is used in the installation of electrical connectors, electrical components, cables, etc., which can solve the problem of accelerating the wear of the steel core and aluminum monofilament of the wire, the hidden dangers in the line operation process, and the easy bending of the drain plate. Deformation and other problems, to achieve the effect of enhancing flow conductivity, increasing stiffness, and reducing concentrated stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

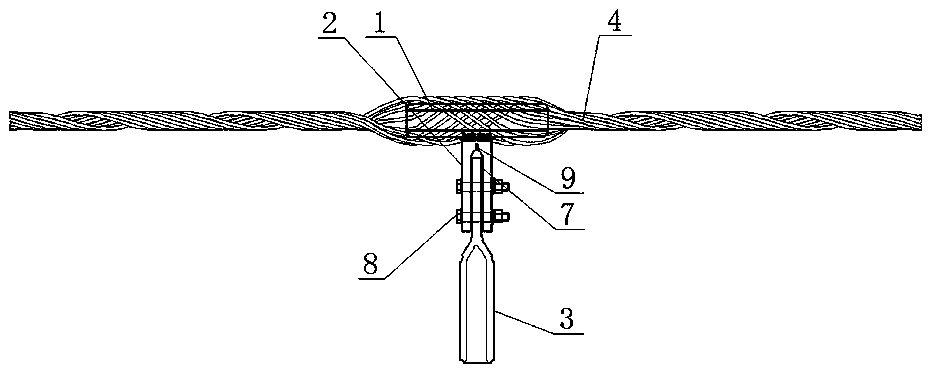

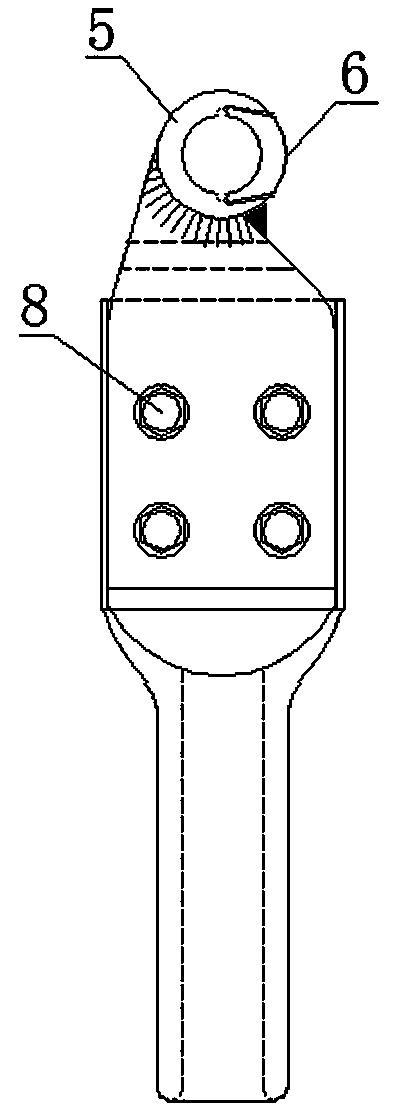

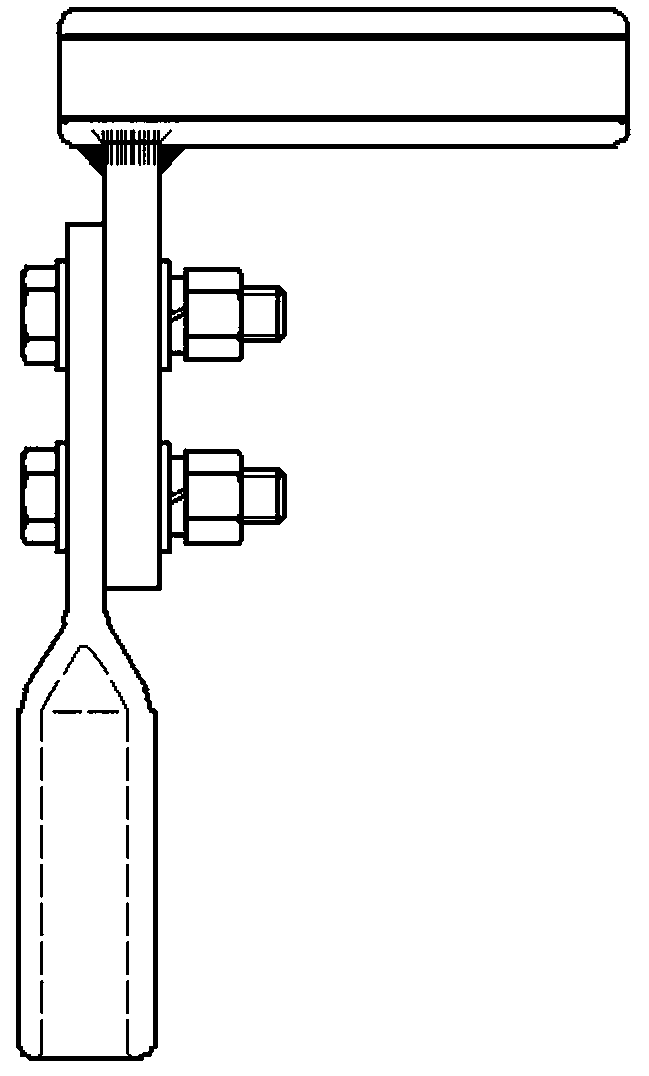

[0025] Such as figure 1 with figure 2 As shown, a new anti-breakage pre-twisted reinforced T-shaped clamp of the present invention includes a clamp main body 1, a drain plate 2, an equipment clamp 3 and a pre-twisted wire 4, and the upper end of the drain plate 2 and the clamp main body The middle part of 1 is fixedly connected, the upper end of the equipment clamp 3 is detachably fixed to the lower end of the drainage plate 2, and the length of the pre-twisted wire 4 is greater than that of the clamp main body 1 and is wound around the outside of the clamp main body 1 and the wire. When the clamp body 1 is fixed on the wire, both ends of the clamp body 1 are tightly pressed against the outside of the wire. The two ends of the clip body are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com