A method for making gift wrapping paper tank outer wall stickers with self-adhesive paste

A production method and technology of wrapping paper, which are applied in the directions of packaging, transportation and packaging, labeling, etc., can solve the problems of increased manpower and repeated work, wrinkles, unevenness, etc., and achieve the effect of increasing manpower and repeated work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

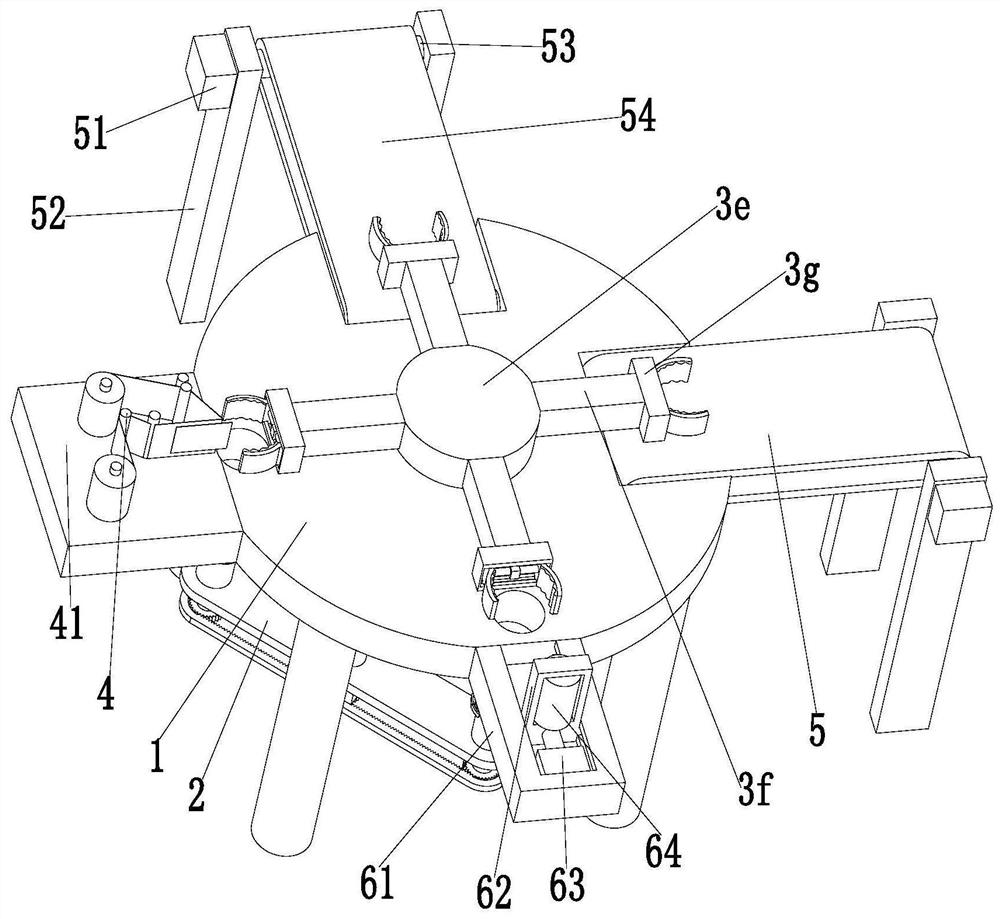

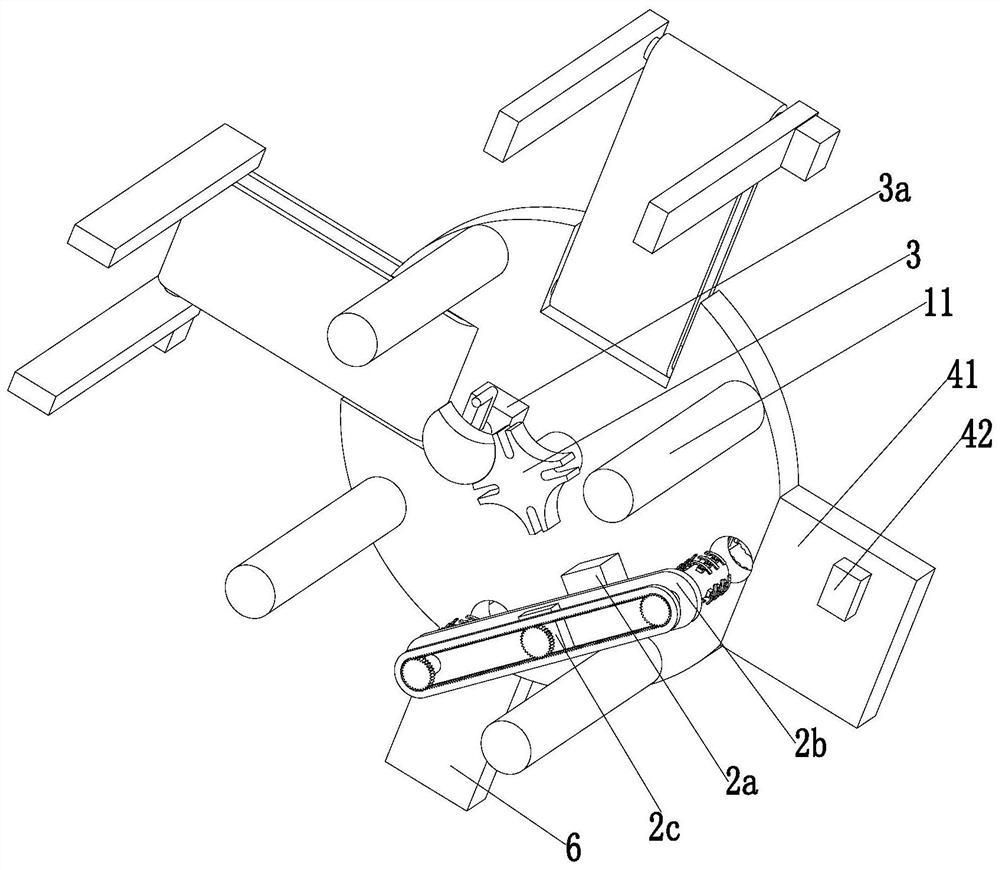

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

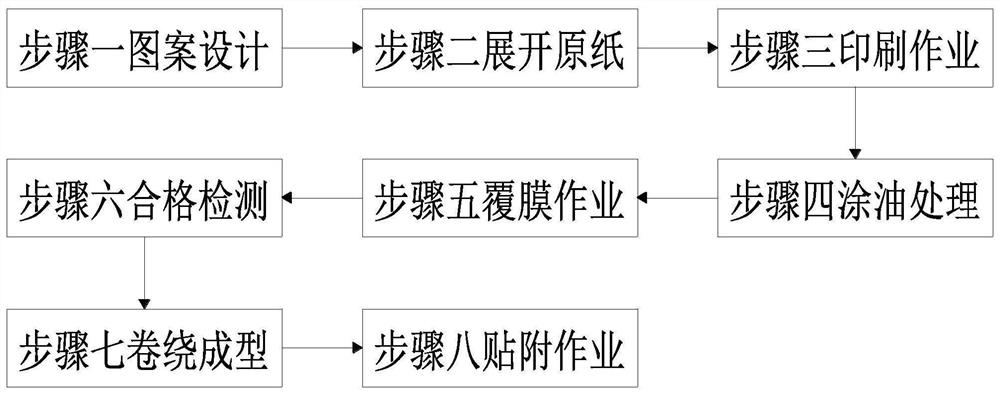

[0038] Such as Figure 1 to Figure 8 Shown, a kind of gift wrapping paper can outer wall sticker stickers production method is characterized in that: mainly comprises the following steps:

[0039] Step 1, pattern design, design the pattern of stickers according to the needs of gift wrapping paper cans;

[0040] Step 2: Unfold the base paper, and unroll the self-adhesive collagen paper rolled into a roll through the paper feeding mechanism and transport it stably to the printing machine;

[0041] Step 3, printing operation, the sticker pattern designed in step 1 is printed on the self-adhesive paper by the printing machine, and the printed self-adhesive paper is obtained;

[0042] Step 4, oiling treatment, using an oiling device to coat a layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com