Torsion actuator

A technology of actuators and components, applied in the field of torsion actuators, can solve problems such as time-consuming and labor-intensive, and achieve the effects of saving costs and improving the efficiency of seedling clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

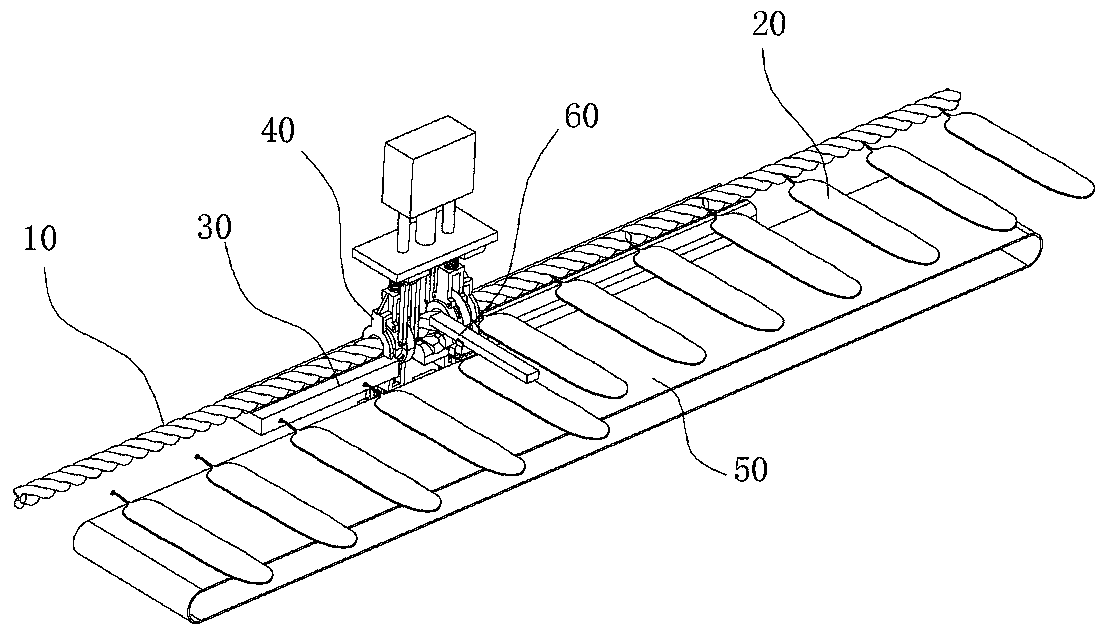

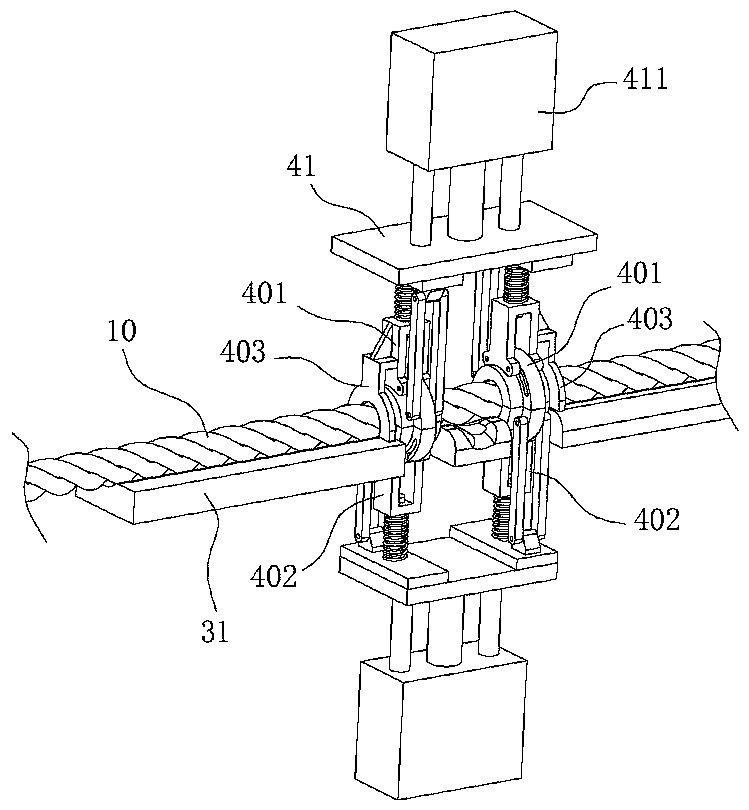

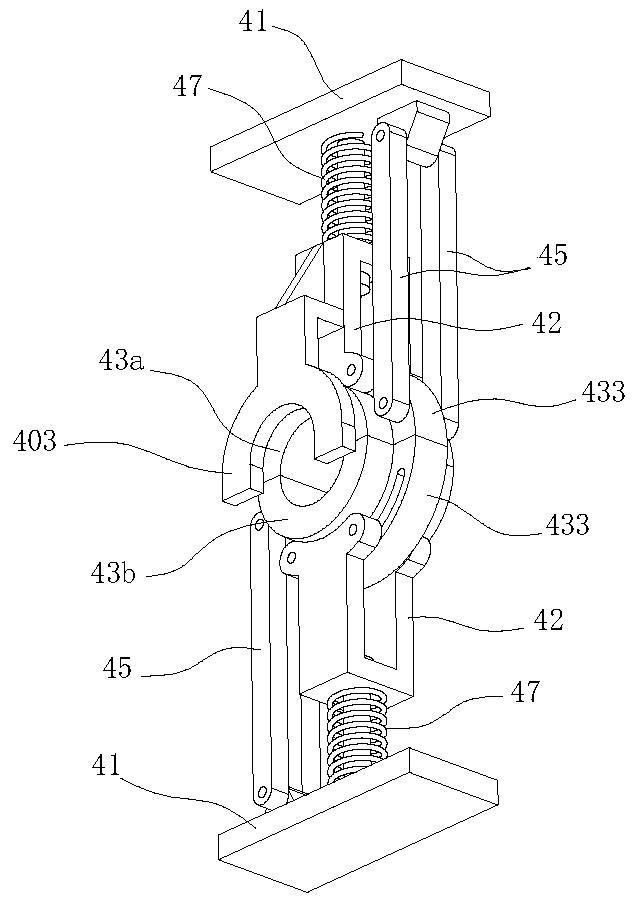

[0023] Such as figure 1 Shown, a kind of kelp clamping device comprises seedling rope conveying mechanism 30, seedling rope twisting mechanism 40, kelp seedling conveying mechanism 50 and kelp seedling transfer mechanism 60, and described seedling rope conveying mechanism 30 is used for conveying seedling rope 10 along itself The length direction is intermittently fed, the seedling rope twisting mechanism 40 is used to twist the seedling rope 10 so that the seedling rope 10 is untwisted, and the kelp seedling conveying mechanism 50 is used to transport the kelp seedlings 20 to the side of the seedling rope twisting mechanism 40 one by one , the kelp seedling transfer mechanism 60 is used to transfer the roots of the kelp seedlings 20 on the kelp seedling conveying mechanism 50 to the gap between the seedling ropes 10 after untwisting. The present invention adopts the seedling rope conveying mechanism 30 and the kelp seedling conveying mechanism 50 to carry out synchronous inte...

Embodiment 2

[0033] A method for transplanting kelp seedlings based on the kelp seedling clamping device described in embodiment 1, comprising the steps of:

[0034] 1) Clean the seedling rope 10, and lay the cleaned seedling rope 10 on the seedling rope conveying mechanism 30. The seedling rope conveying mechanism 30 is used to convey the seedling rope 10 and feed it intermittently along its own length direction. The rope conveying mechanism 30 comprises a seedling rope conveying groove 31, and conveying rollers arranged on the lengthwise direction of the seedling rope conveying groove 31, the conveying roller is a pair of rollers, and the seedling rope 10 passes between the rollers;

[0035] 2) Remove the kelp seedlings 20 with a length of 30-45 cm from the seedling curtain, and lay the kelp seedlings 20 equidistantly on the kelp seedling conveying mechanism 50. The conveyer belt that 31 directions are arranged, and described conveyer belt top is provided with sprinkler, and the root por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com