Novel portable spiral pipe chamfering device

A spiral tube, portable technology, applied in the field of new portable spiral tube chamfering device, can solve the problems of low machining accuracy, unsuitable chamfering, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

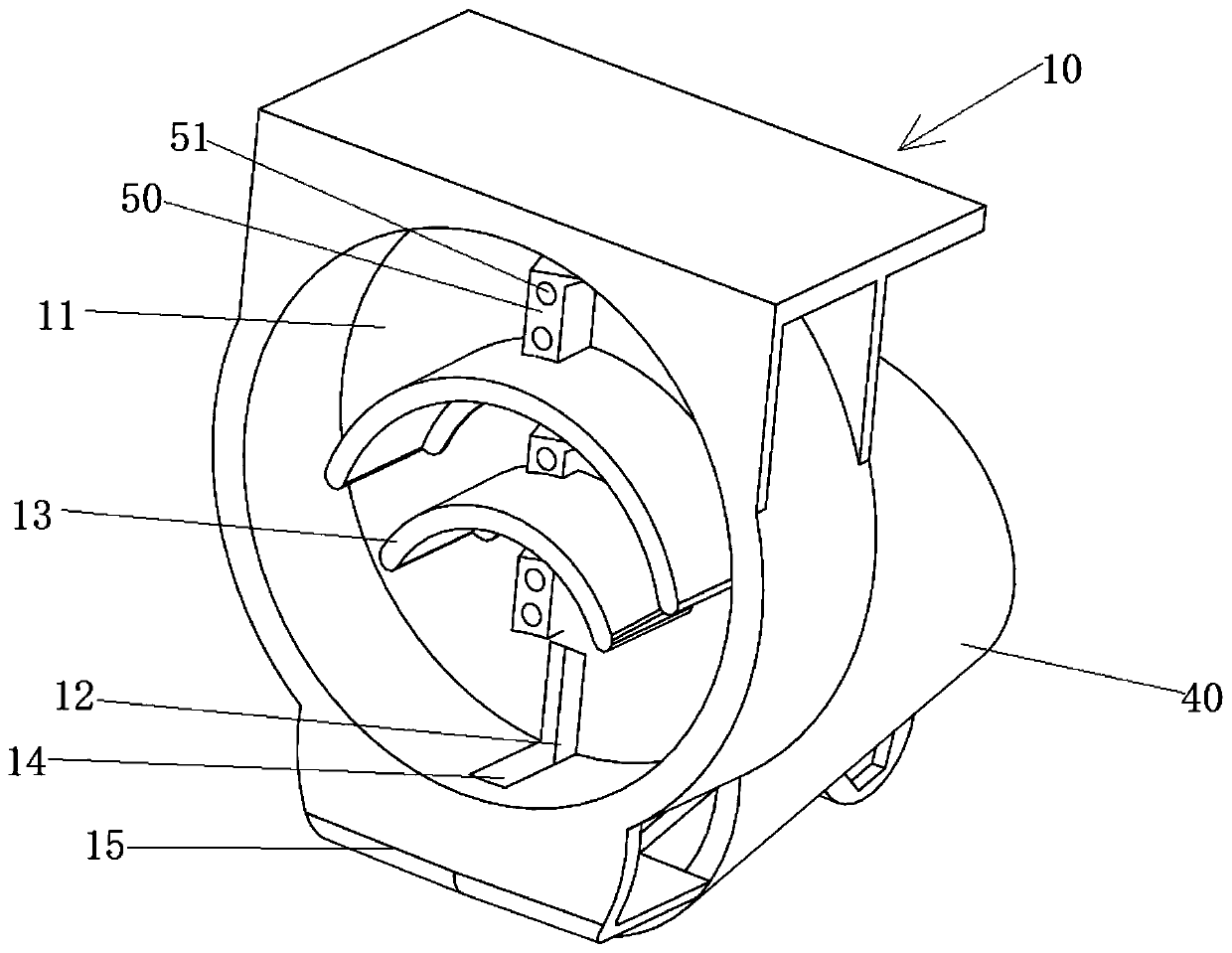

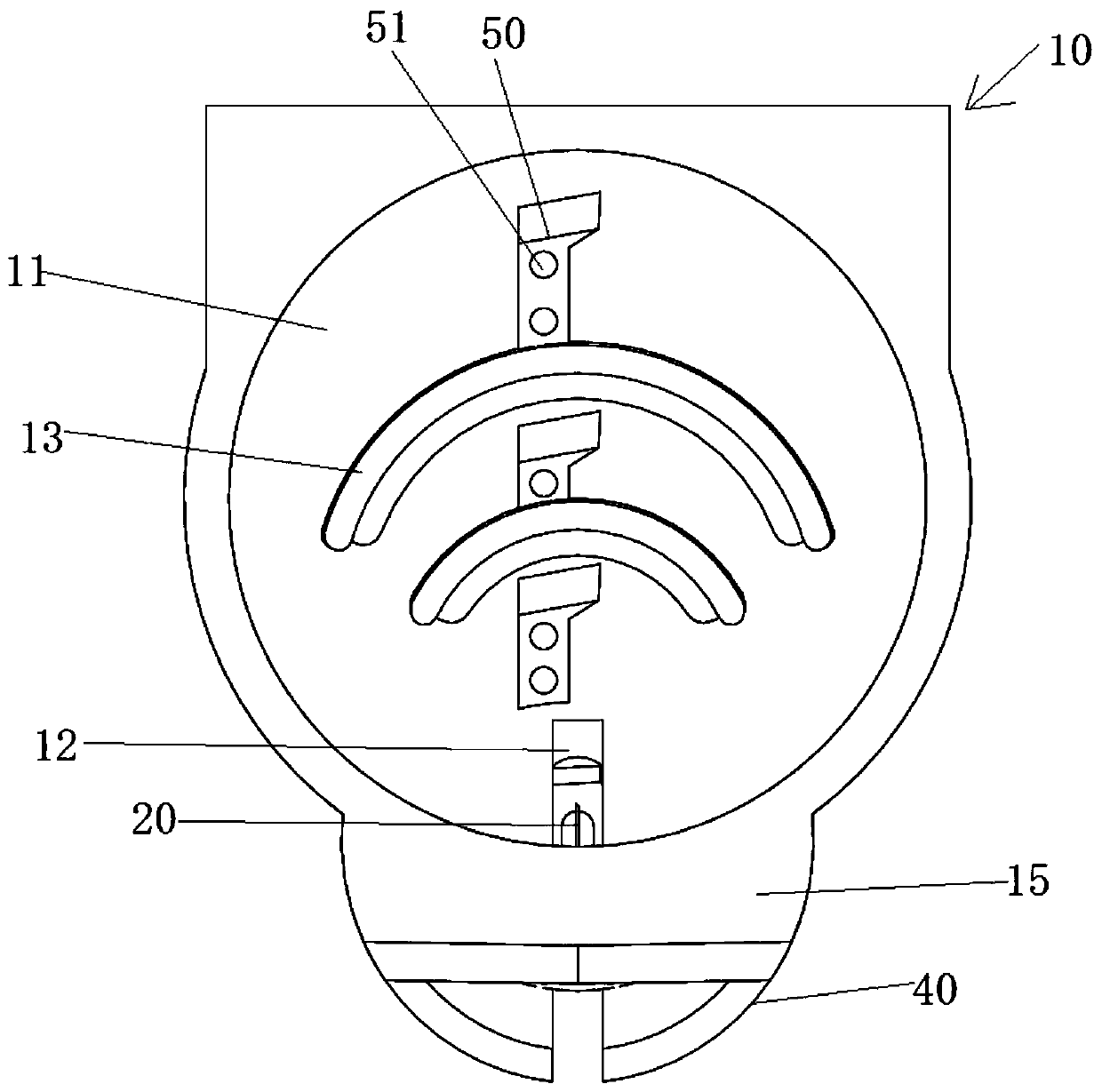

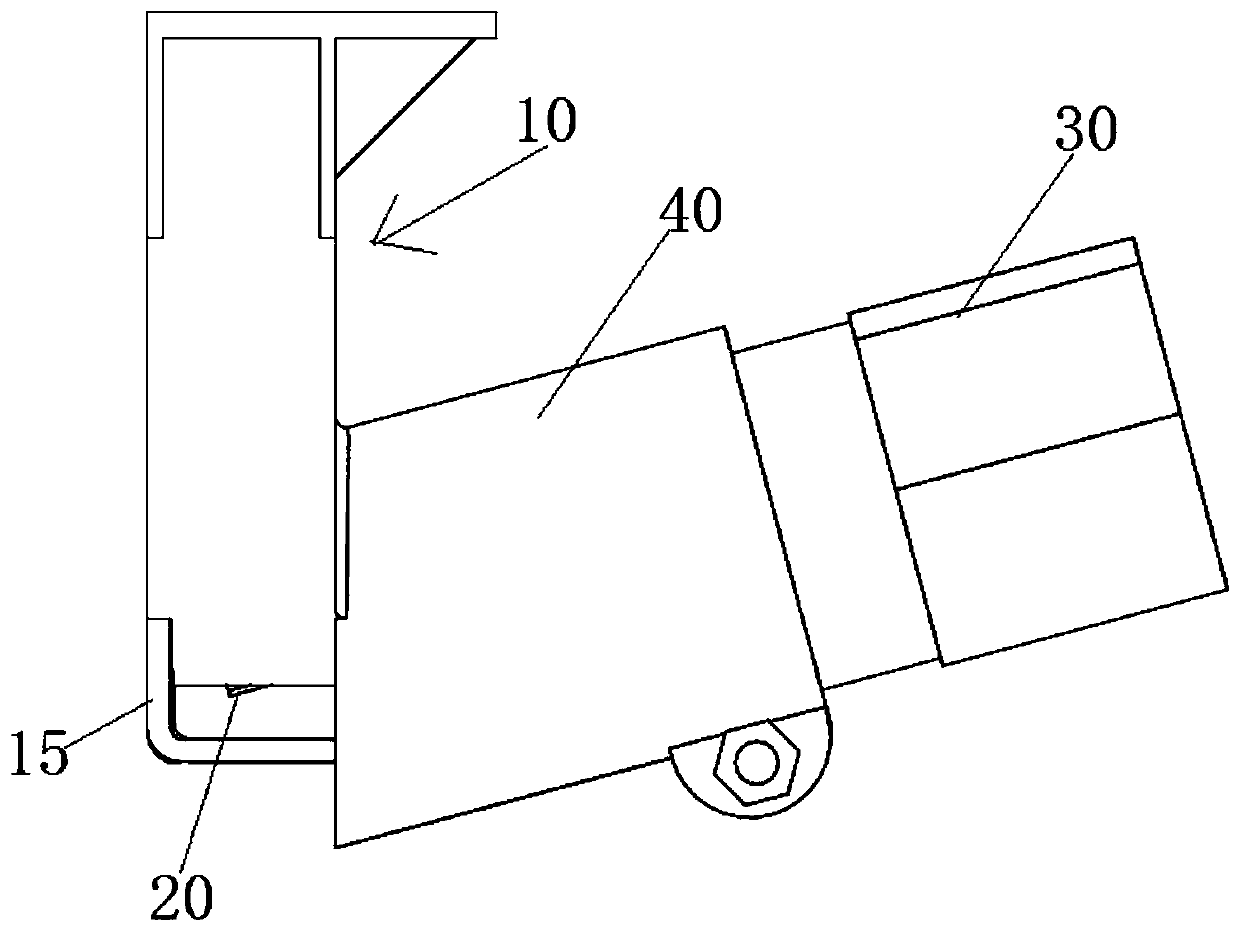

[0026] see Figure 1 to Figure 9 A new type of portable helical pipe chamfering device shown includes a housing 10 and a cutting chamber 11 arranged on the housing 10 for placing pipes, and a cutting groove 12 is arranged on the cutting chamber 11, and the cutting groove 12 is used for The first cutting part 20 chamfers the pipe, and the first cutting part 20 is arranged on the cutting groove 12 in an inclined shape. The first cutting member 20 is preferably a cutting knife, and the setting direction of the first cutting knife 20 is opposite to the rotation direction of the pipe to realize the chamfering effect. The first cutting unit 20 is connected to a driving unit 30, and the driving unit 30 is connected to an external power source. The drive part 30 is preferably an electric...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap