Silicon wafer chamfering device

A technology of chamfering device and silicon wafer, which is applied in the direction of grinding drive device, grinding machine, grinding machine parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

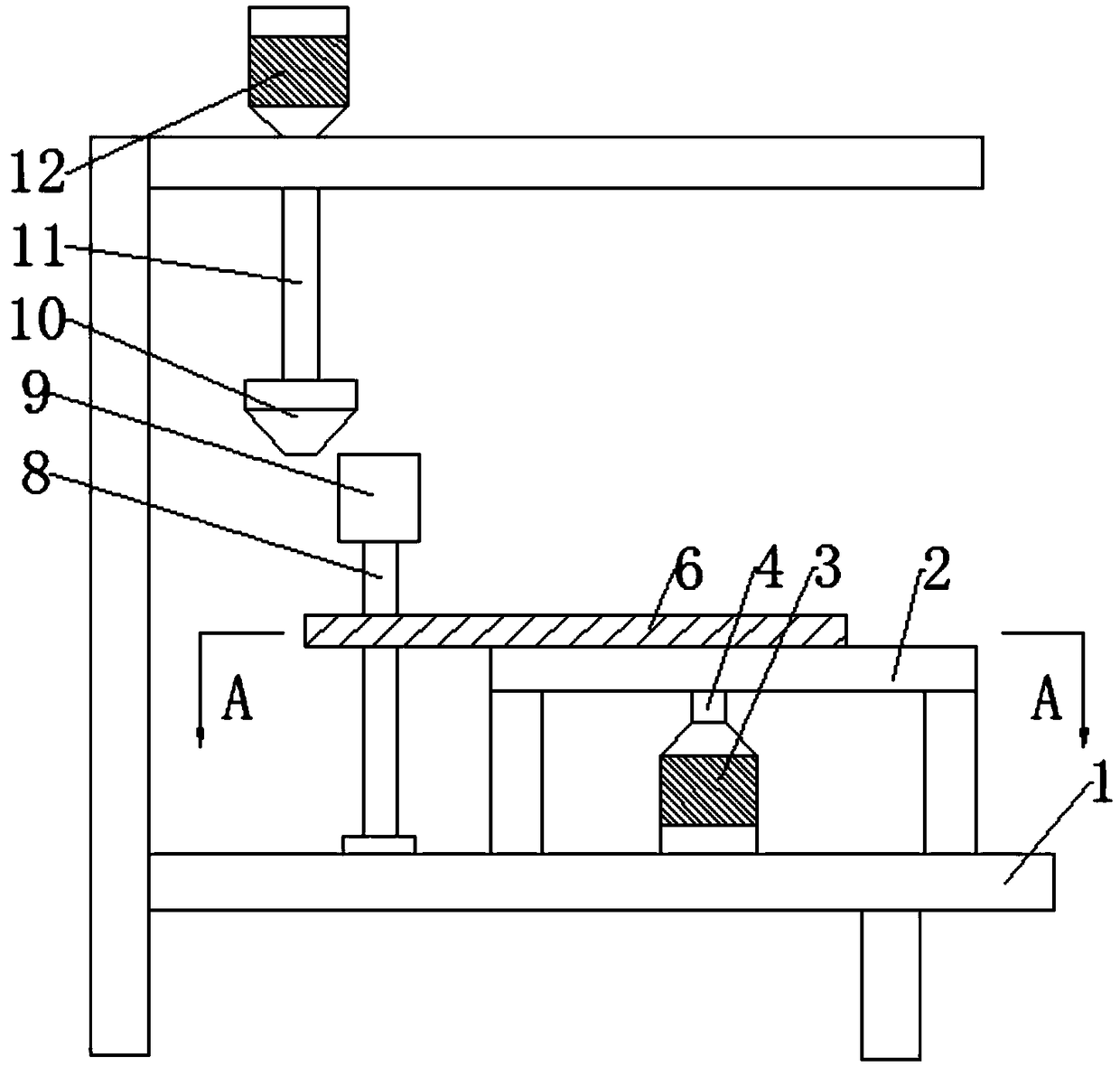

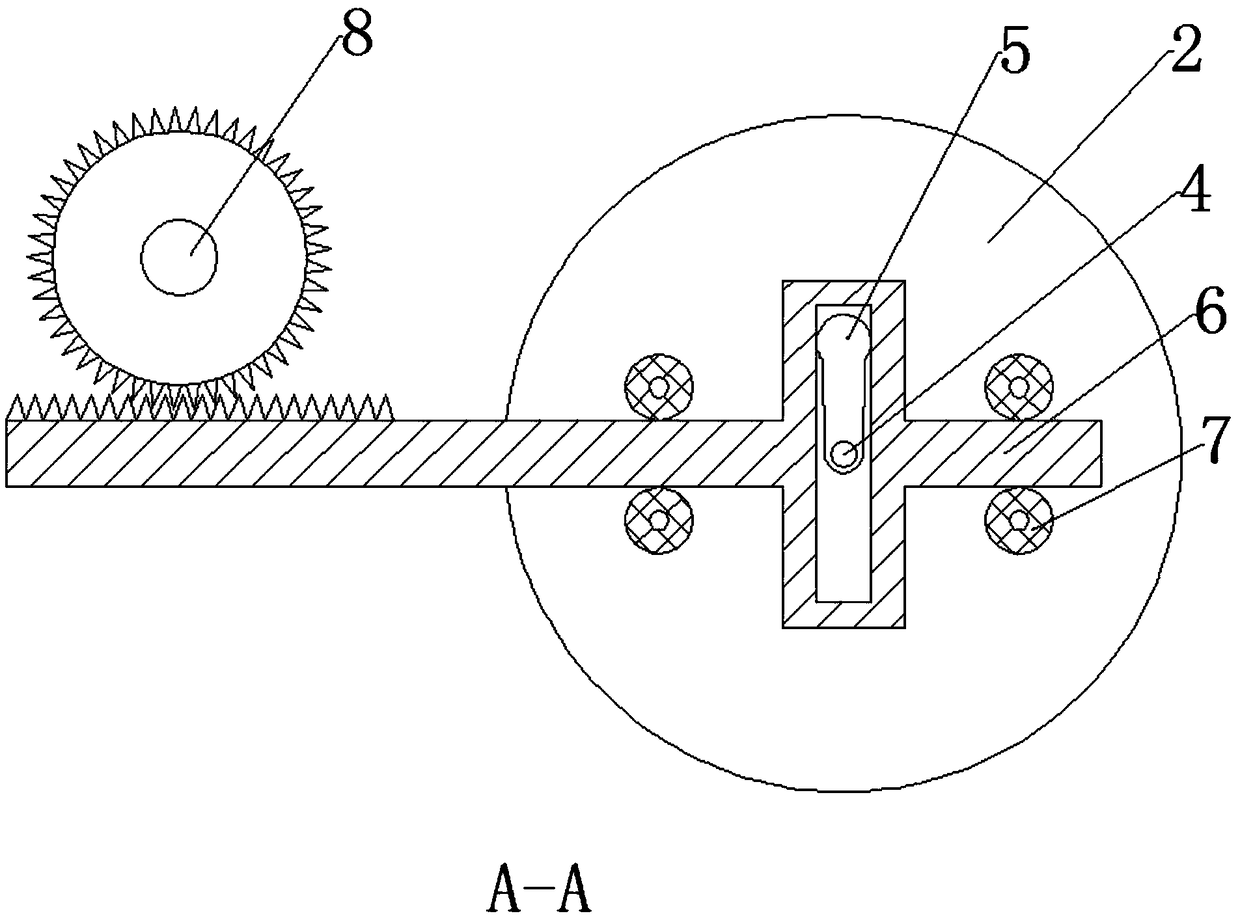

[0026] A silicon wafer chamfering device, comprising a mounting frame 1, a second motor 12 is arranged on the mounting frame 1, a grinding wheel 10 is connected to a second output shaft 11 of the second motor 12, and a fixing table 9 is arranged under the side of the grinding wheel 10, A rotating shaft 8 is also provided, and one end of the rotating shaft 8 is connected with the fixed table 9, and the other end of the rotating shaft 8 is installed on the mounting frame 1 through a bearing, and the rotating shaft 8 is also sleeved with gears; A motor 3, the output end of the first output shaft 4 of the first motor 3 is connected with a rotating rod 5, the rotating rod 5 is covered with a traverse rod 6, and the traverse rod 6 is placed on the placement table 2 and can slide arbitrarily, Limiting blocks 7 are also arranged on both sides of the traversing rod 6, and the limiting blocks 7 are fixed on the placement table 2. A cavity is provided inside the traversing rod 6, and the ...

Embodiment 2

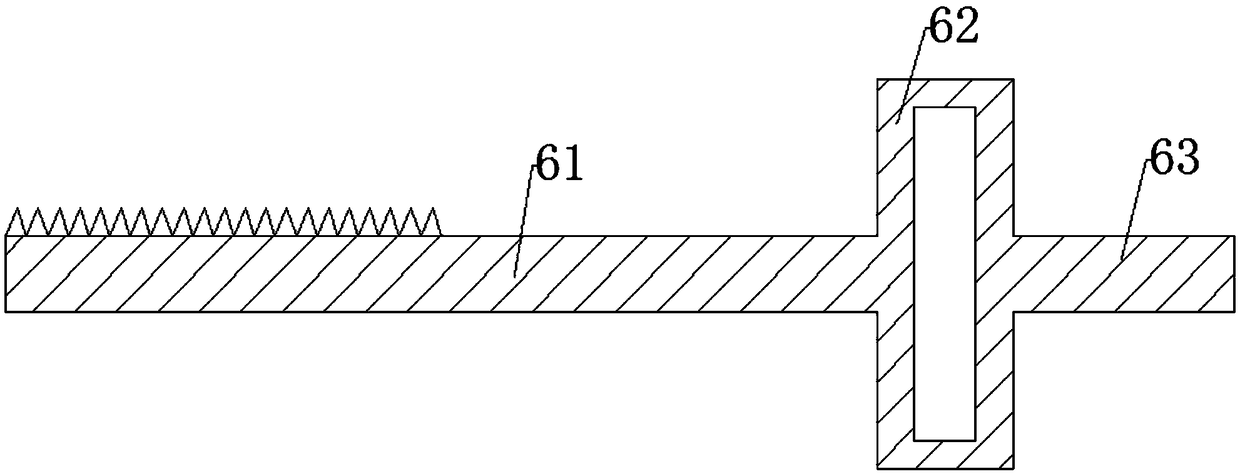

[0028] On the basis of Embodiment 1, the traversing rod 6 includes a first connecting rod 61, a connecting block 62, and a second connecting rod 63 connected in sequence. Teeth are provided on the side of the first connecting rod 61 corresponding to the position of the gear, and the middle part of the connecting block 62 A cavity is provided; four limit blocks 7 are provided, two limit blocks 7 are arranged on both sides of the first connecting rod 61, and the other two limit blocks 7 are arranged on both sides of the second connecting rod 63, four The limiting blocks 7 are distributed in a rectangular shape.

Embodiment 3

[0030] On the basis of the above embodiments, the limit block 7 is a pulley whose center is fixed on the placement platform 2 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap