An ultra-long flap, a flap machine, and a welding method for an ultra-long flap

A flipping and super-long technology, applied in the field of flipping machines, can solve the problems of easy deformation of long boards, short length, insufficient load capacity, etc., and achieve the effect of small overall deformation, weight reduction, and improved lubrication effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

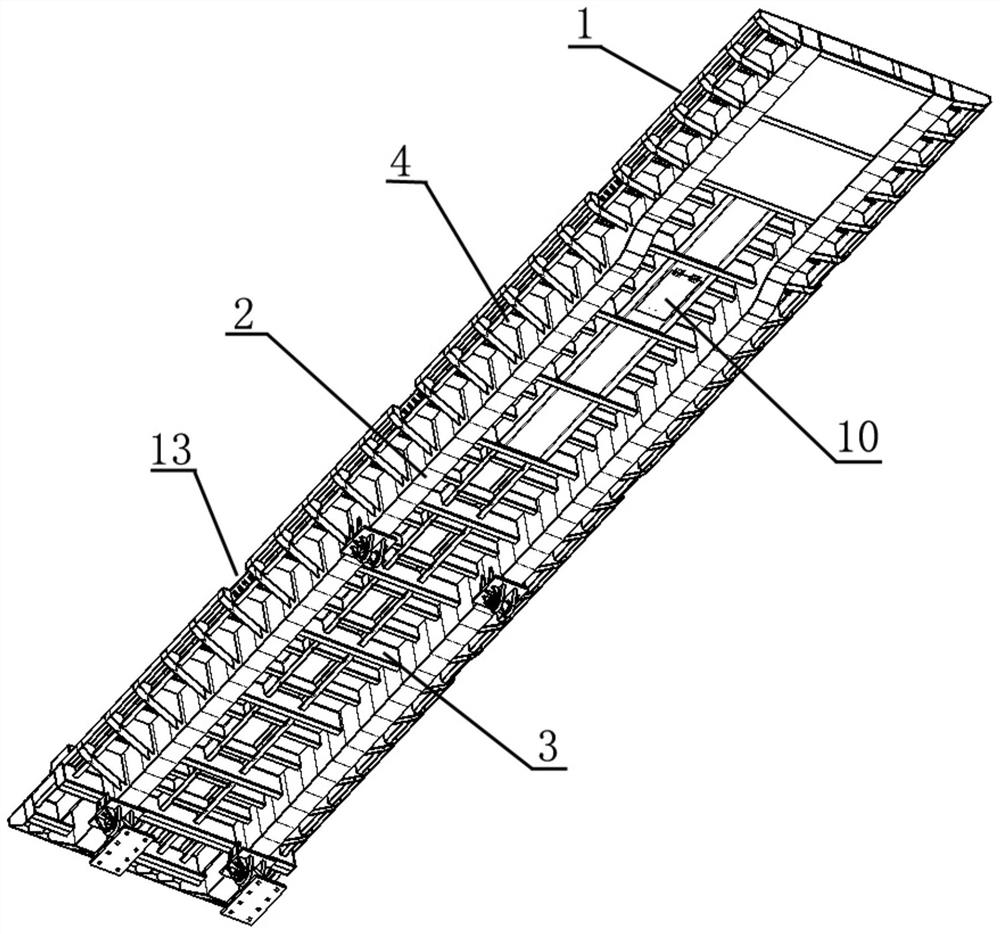

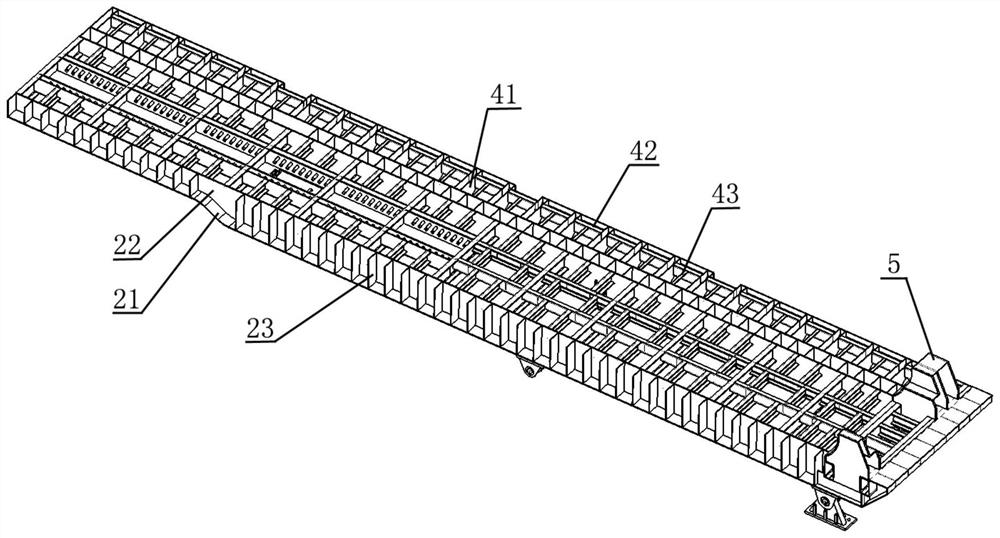

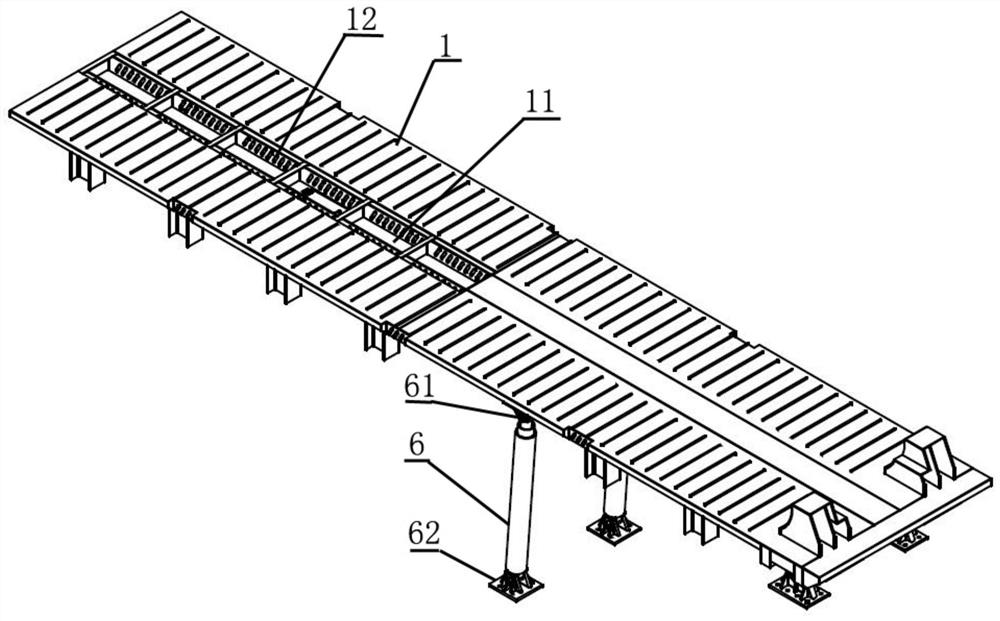

[0033] Such as Figure 1 to Figure 5 As shown, the super-long turning plate and turning machine in this embodiment include: panel 1, main beam 2, connecting beam 3, reinforcing plate group 4, stopper 5, hydraulic cylinder 6, fixing seat 7, connecting seat 8, Pin shaft 9, maintenance opening 10, hook groove 11, hook hole 12, rope fixing notch 13, bottom plate 21, side plate 22, partition plate 23, reinforcement plate 41, short vertical beam 42, short beam 43, first hinge seat 61 , The second hinge seat 62, the first bushing 71, the second bushing 72, the oil channel 91 and the oil groove 92.

[0034] continue to refer figure 1 and figure 2 , the bottom surface of the main board 1 is provided with two parallel main beams 2, the main beam 2 extends from one end of the main board 1 to the other end of the main board 1, and a connecting beam 3 of I-shaped steel is welded between the two main beams, and the connecting beam 3 It is vertically connected with the main beam 2, and o...

Embodiment 2

[0038] A welding method for super-long flaps, such as Figure 6 shown, including the following steps:

[0039] Preparation before welding: V-shaped grooves with blunt edges are made on each welding part, and the surface rust, oil and moisture on both sides of the welding part are cleaned;

[0040] S1. Process the bottom plate of the main beam: according to the needs, perform secondary bending on the bottom plate 21 to ensure that the bending edge at the bending place becomes a smooth transition;

[0041] S2. Welding the main girder side plate: use a welding rod with a diameter of 4mm, the welding rod grade is ER50-6, and a welding current of 150-160A is used to fully weld the two sides of the bottom plate 21 with the blank surface of the side plate 22 respectively , and ensure that the board surfaces of the bottom plate 21 and the side plate 22 are perpendicular to each other;

[0042] S3. Welding main girder partitions: first spot-weld the partitions 23 located at the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com