A Construction Method for Small Angle Intersecting Tunnels

A technology of crossing tunnels and construction methods, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve problems such as subsidence, inability to construct tunnel structures that meet design requirements and usage requirements, and reduce impact and subsidence deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A construction method for a small-angle cross tunnel, comprising the following steps:

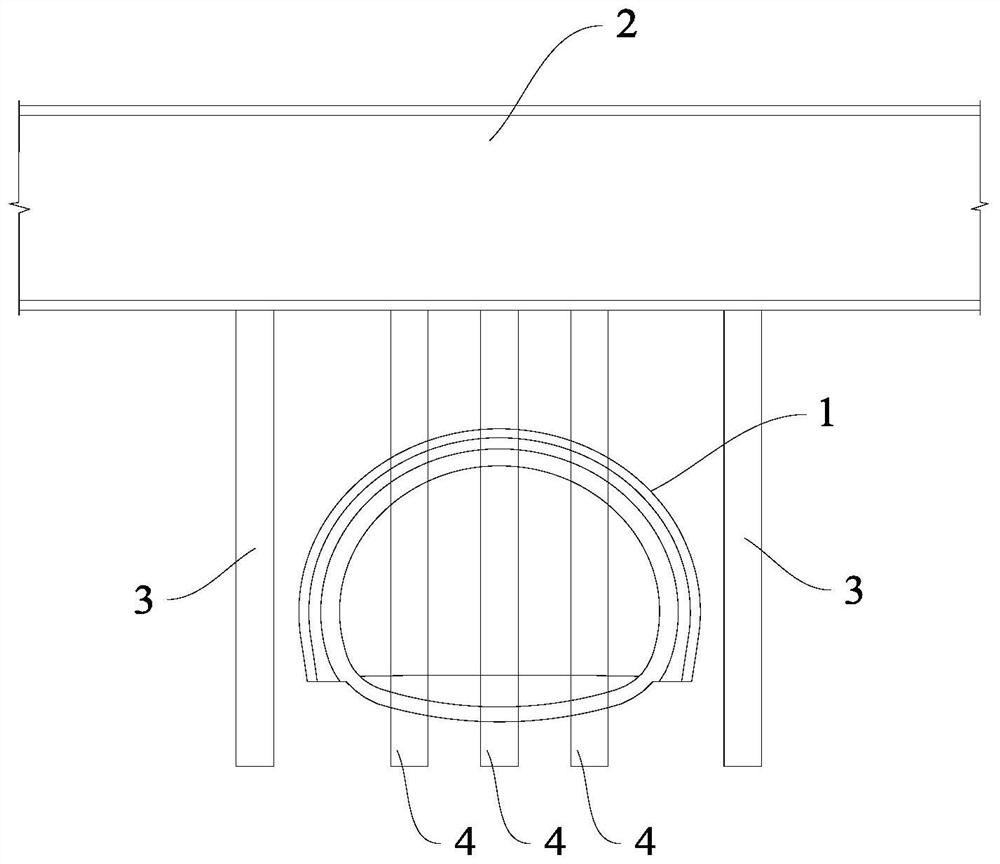

[0032] Step 1: After the upper tunnel 2 is constructed to the intersection section, the intersection section of the upper tunnel 2 is excavated by the step method, and the arch wall initial support of the intersection section of the upper tunnel 2 is immediately applied;

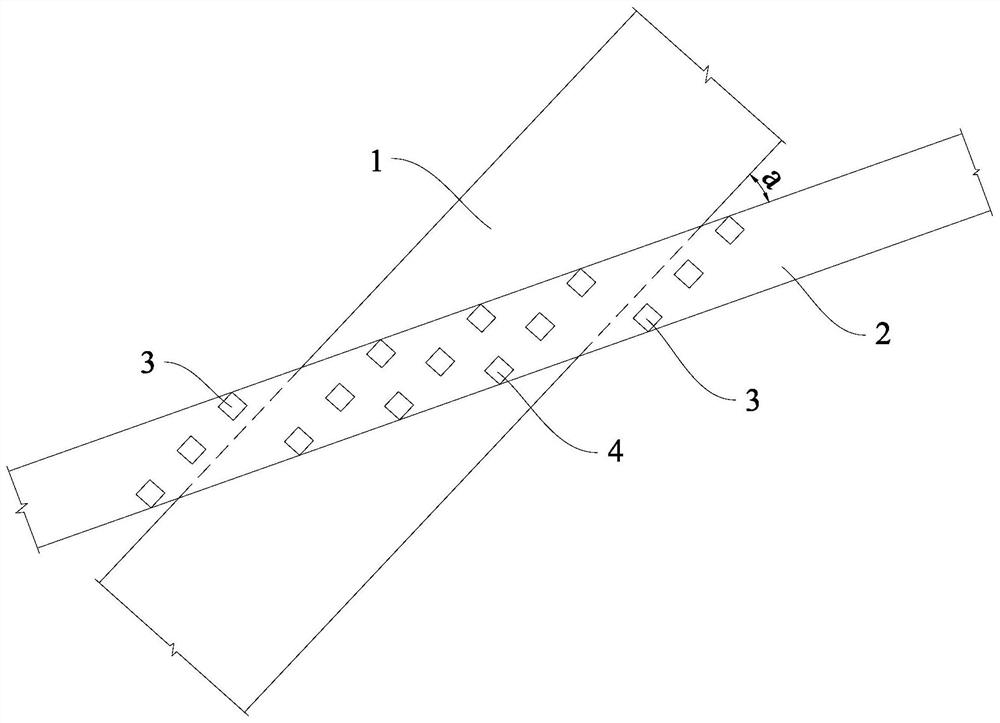

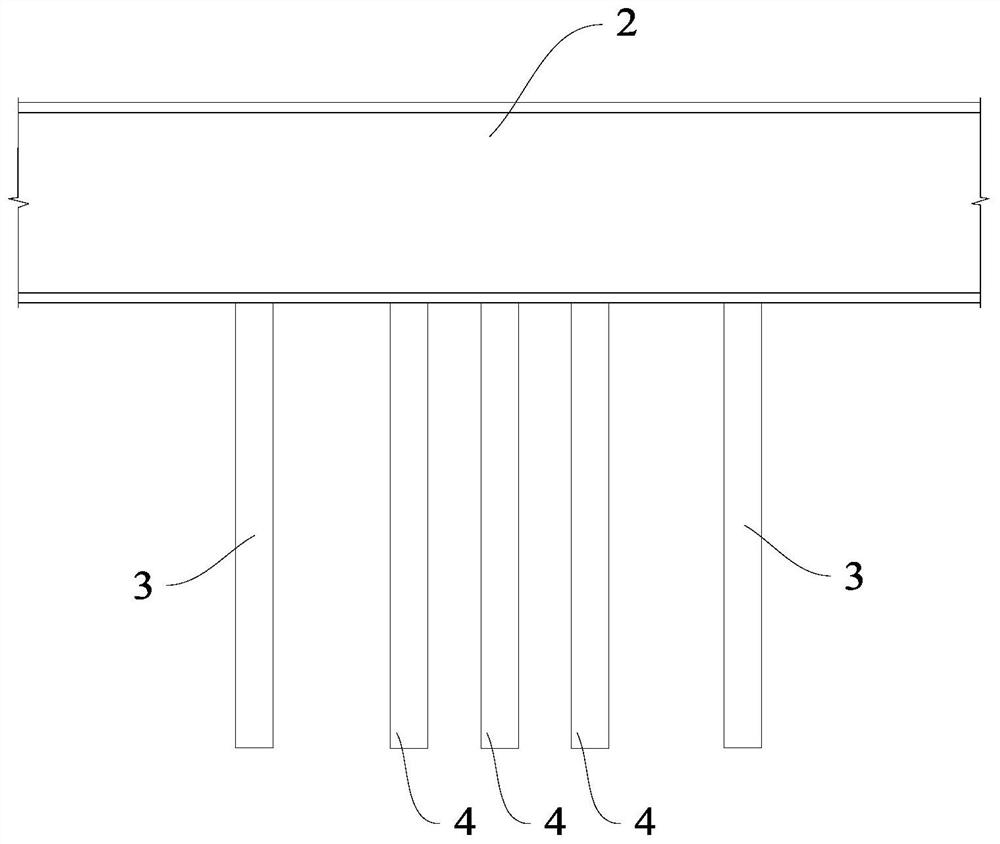

[0033] Step 2: If Figure 1-Figure 3 As shown, support piles are installed at intervals downward from the upper tunnel 2, the support piles are glass fiber piles, the depth of the support piles is deeper than that of the lower tunnel 1, and the support piles include the intersection section of the lower tunnel 1 The second support pile 4 inside, and the first support pile 3 located on both sides of the intersection section of the tunnel 1 below. During construction, first construct the first support pile 3, place the steel cage as a whole to pour the pile foundation to the pile end, reserve the main reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com