Clutch Control

A clutch control and clutch device technology, applied in the direction of clutches, mechanical equipment, etc., can solve the problems of clutch work delay, delay, and no mention of clutch cut-off performance, etc., to achieve the effect of improving responsiveness and suppressing work delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

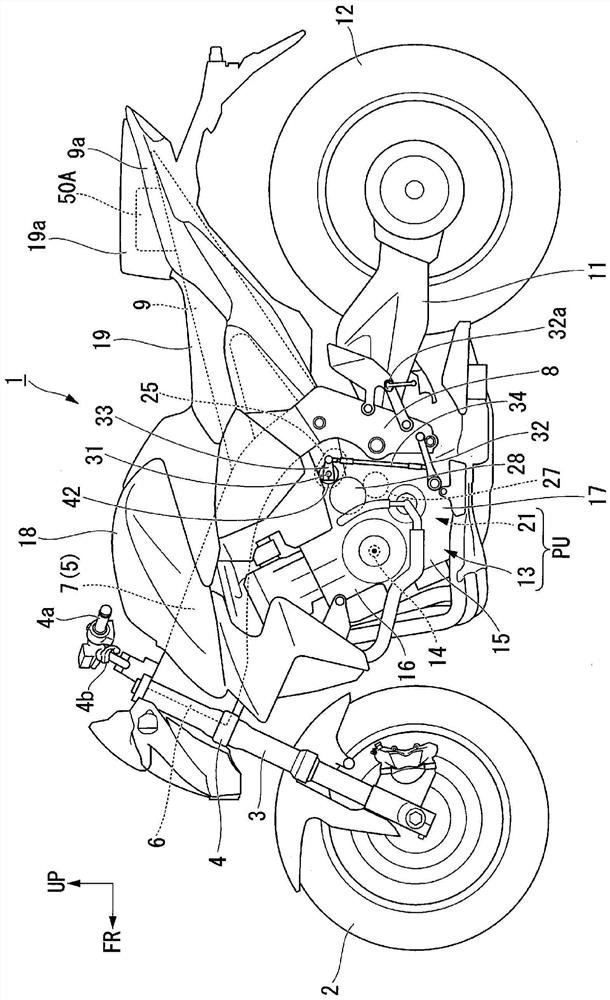

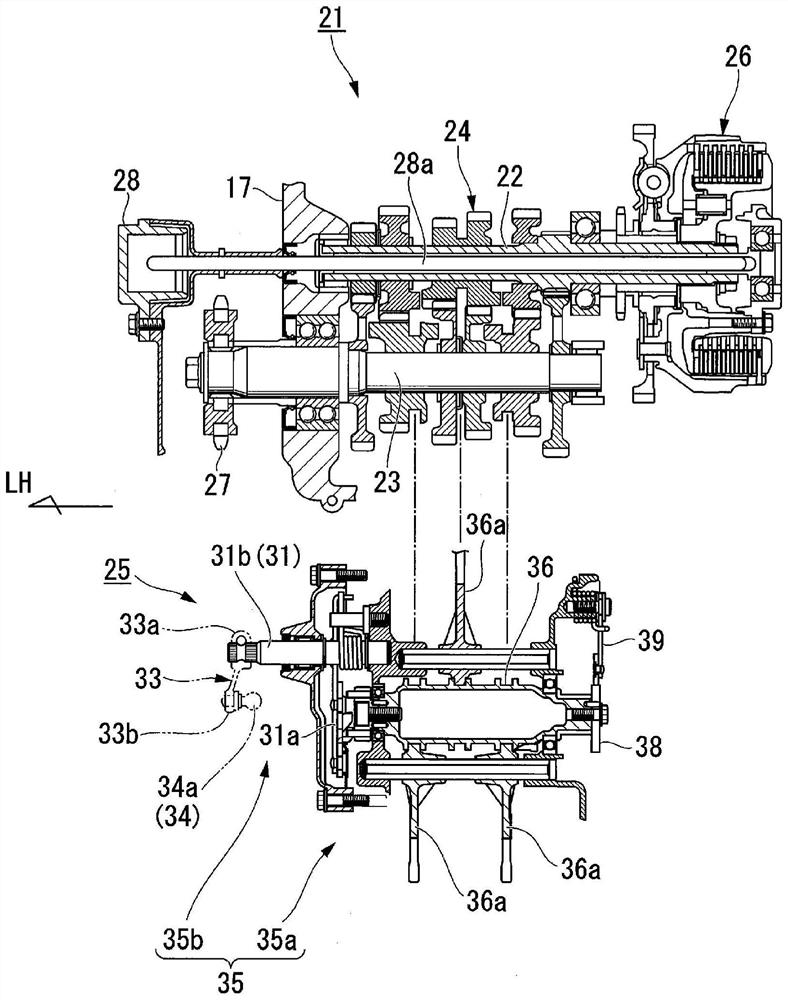

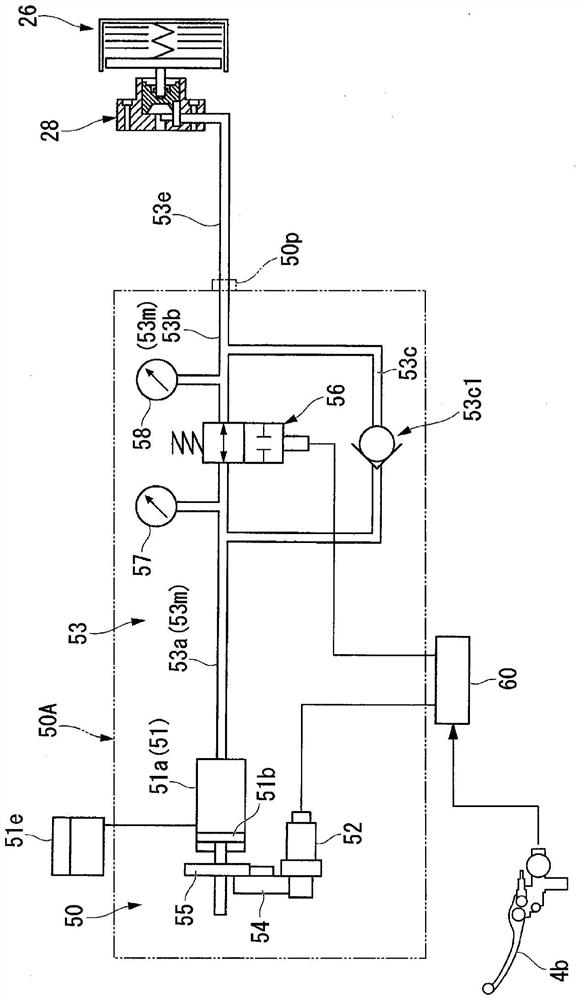

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings. It should be noted that directions such as front, rear, left, and right in the following description are the same as those in the vehicle described below, unless otherwise specified. In addition, an arrow FR indicating the front of the vehicle, an arrow LH indicating the left side of the vehicle, and an arrow UP indicating the upward direction of the vehicle are shown at appropriate places in the drawings used in the following description.

[0043]

[0044] like figure 1 As shown, this embodiment is applied to the motorcycle 1 which is a straddle-type vehicle. The front wheel 2 of the motorcycle 1 is supported by the lower end portions of a pair of left and right front forks 3 . Upper portions of the left and right front forks 3 are supported by a head pipe 6 at a front end portion of the body frame 5 via a steering rod 4 . On the top bridge of the steering rod 4, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com