Self-conducting filter pipeline

A self-conducting, pipeline technology, applied in the field of pipelines, to achieve the effect of increasing service life, increasing cleanliness, and reducing the number of cleanings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

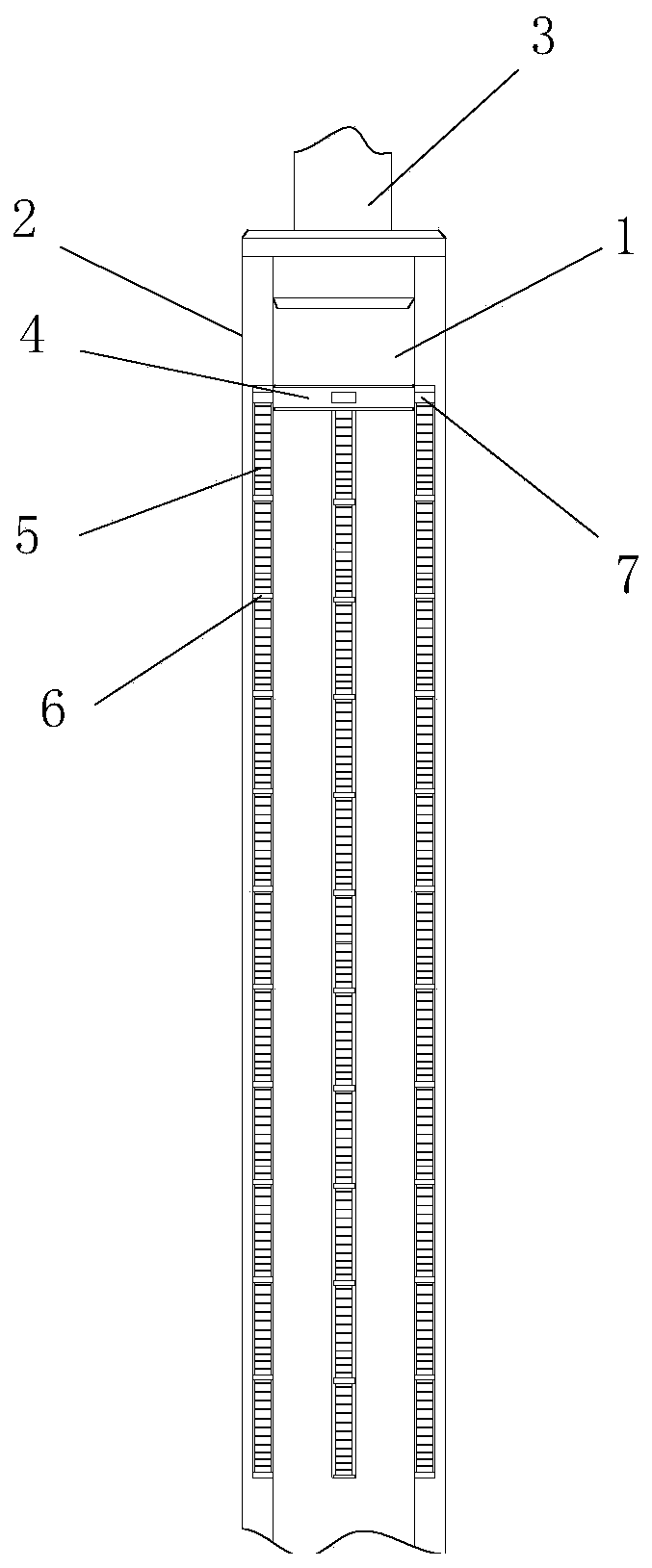

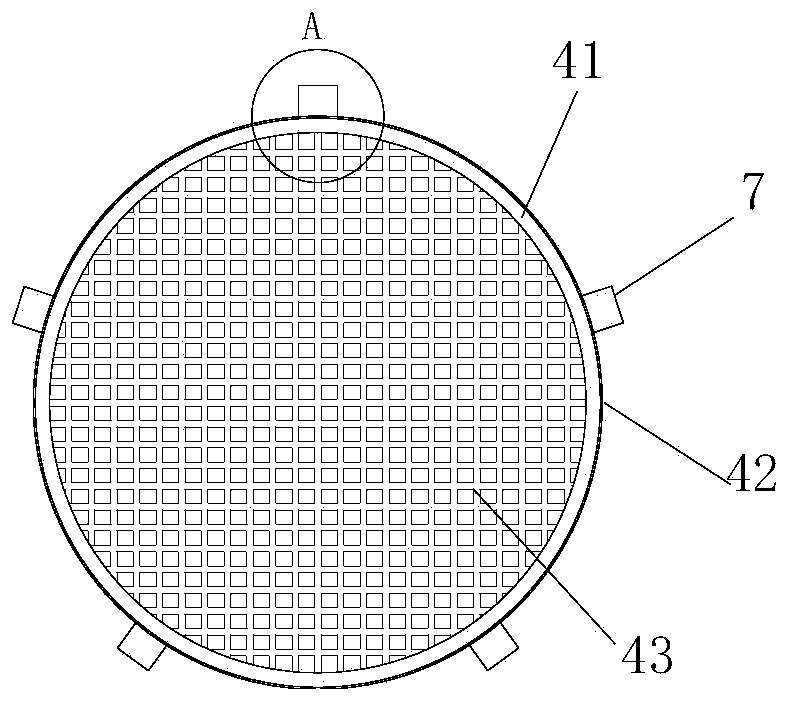

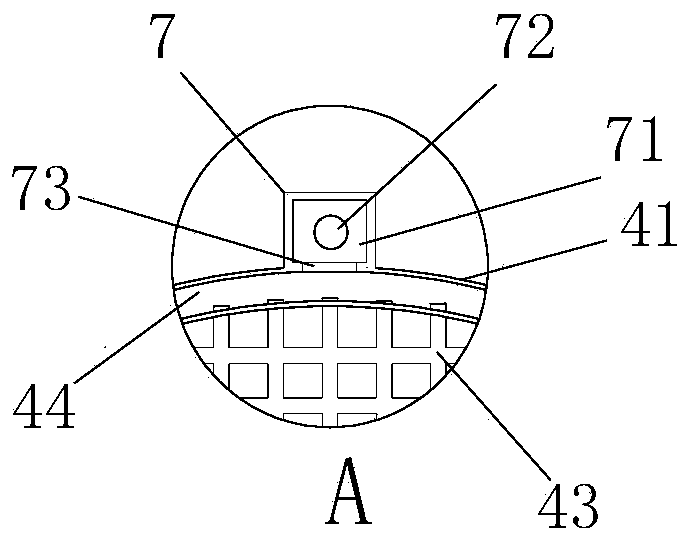

[0018] like figure 1 As shown, the self-guiding filter pipeline includes a straight pipe 2, one end of the straight pipe 2 is connected to the input pipeline 3, a discharge channel 1 is provided in the straight pipe 2, and a filter device is arranged at the end of the discharge channel 1 near the input pipeline 3 4. The outer wall of the filter device 4 is provided with more than one transition block 7, and the transition blocks 7 are all slid and buckled into the chute provided on the inner wall of the discharge channel 1. The chute extends along the length direction of the straight pipe 2, and the chute There are more than one elastic gas storage parts 5 inside, and more than one elastic gas storage parts 5 are arranged along the length direction of the chute. An engaging piece 6 is arranged between adjacent elastic air storage parts 5, and the connecting piece 6 The upper and lower elastic gas storage parts 5 are connected and conducted, the transition block 7 contacts and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com