A Control Method of Variable Geometry Mixed Flow Turbocharger

A technology of turbocharger and control method, applied in engine control, machine/engine, combustion engine, etc., can solve the problems of delayed response, slow starting response, poor low-speed torque characteristics, etc., to save fuel and improve exhaust gas. quality, the effect of reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

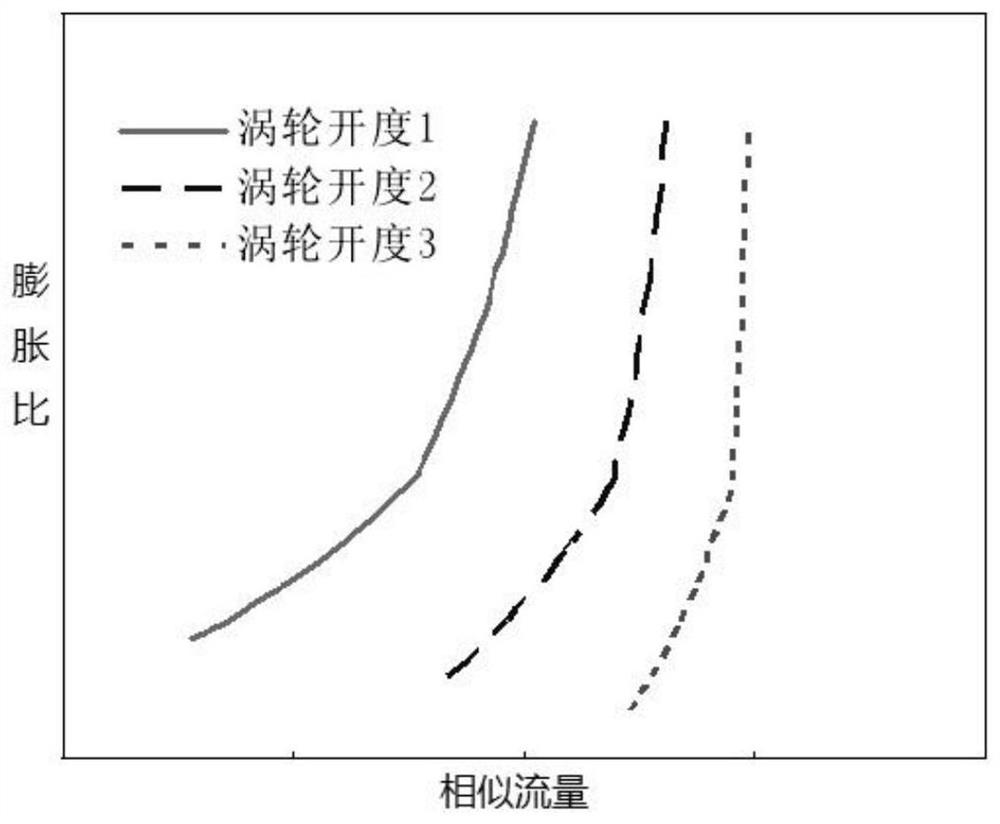

[0033]participateFigure 1 - Figure 4For a variable geometric mixed flow turbocharger control method, the main control element has a display panel, a controller, a direct step motor drive chip, an electric push rod, and the like, the main control method includes supercharger performance analysis, controller The logical program is written, mainly using sensor technology to collect diesel exhaust pressure, which mainly includes the following steps:

[0034]Prepassure is initially adjusted: According to the control characteristics of the DC step motor driver selected, a set of control systems is designed by the selected controller.figure 1 For the main control interface. For the push rod, it is a force source as a thrust source, and its main drive mode is pulsed, and the frequency setting is provided in the main control interface to control the speed of the push rod, the selected step motor driver maximum input frequency is 16000 Hz.

[0035]Preparator is mainly divided into pusher calibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com