Dairy product and process

An emulsifier, skim milk technology, used in ultra-high temperature cream, manufacturing UHT cream products, manufacturing such cream and products, coffee cream and whipping cream field, can solve problems such as cream defects, pouring difficulties, turning into solids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-5

[0083] 1. General method

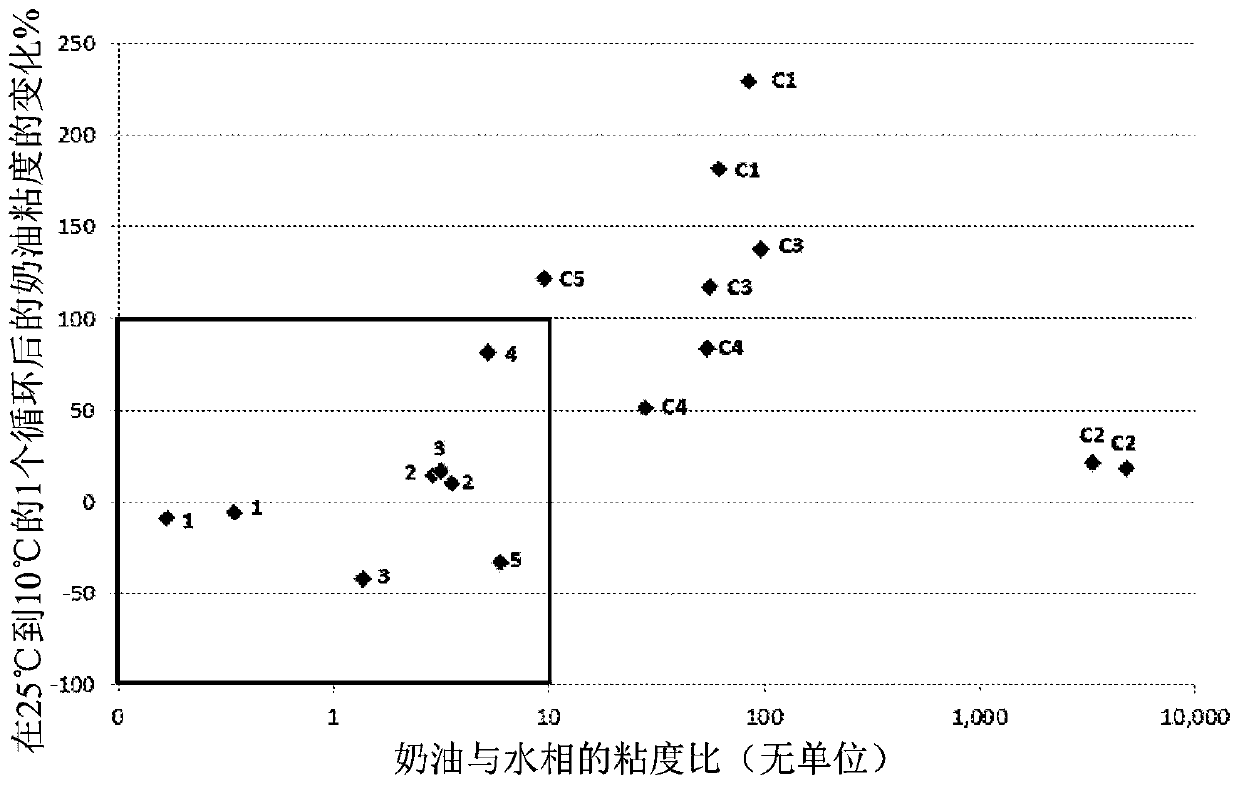

[0084] 1.1 Temperature cycle

[0085] Temperature cycle or subsample each cream in its original unopened packaging into sterile containers. To prevent microbial growth, 0.02 wt% sodium azide was added to all subsampled cream from the 20 wt% stock solution. All creams were first cooled to 5°C for at least 24h before temperature cycling. To complete 1 cycle from 25°C to 10°C, the cream was then transferred to a temperature-controlled storage unit maintained at 25°C for 24h, then stored in a separate temperature-controlled storage unit maintained at 10°C for 24h. All recycled cream was then transferred back to cold storage (5°C) for 24h before further testing.

[0086] 1.2 Aqueous phase extraction

[0087]Transfer approximately 25 to 30 g of each cream to a 50 mL centrifuge tube. The tubes were then placed in an oven at 50°C for 1 h to melt the cream before being transferred to a centrifuge rotor preheated to 40°C in a centrifuge (Beckman Coulter A...

example 6-10

[0134] 1. Composition

[0135] The compositions of Tables 3 and 4 (Examples 6-8) were prepared by the following procedure.

[0136] 1) The AMF of each formulation was weighed and placed in a ~50°C water bath to melt the fat.

[0137] 2) Add lecithin, mono-diglycerides, PGMS to AMF and stir.

[0138] 3) Water was weighed in a stainless steel beaker and placed in a water bath at 65°C.

[0139] 4) Dry blend MPC, stabilizer blend and polyphosphate and add slowly to a vortex of warmed water. Once added, cover and mix for 10 minutes.

[0140] 5) Remove from water bath and add melted AMF-emulsifier blend and subject to high shear mixing (Ultraturrax) at max rpm for 3 minutes. Place again in a 65°C water bath, cover and keep.

[0141] 6) Heat treat the sample with a laboratory heating coil in a 95°C water bath and hold at 90°C for 10 minutes.

[0142] 7) Homogenize at 65°C at 50 / 20 bar.

[0143] 8) Cool the cream in a tank filled with cold water.

[0144] 9) Add sodium azide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com