A component for automatic locking of a rotating shaft

An automatic locking and rotating shaft technology, which is applied to the parts, pivots, and pivot connections of lighting devices, can solve the problems of limited rotation angle of lamps and lamps that cannot be automatically locked, and achieve the effect of improving the swing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

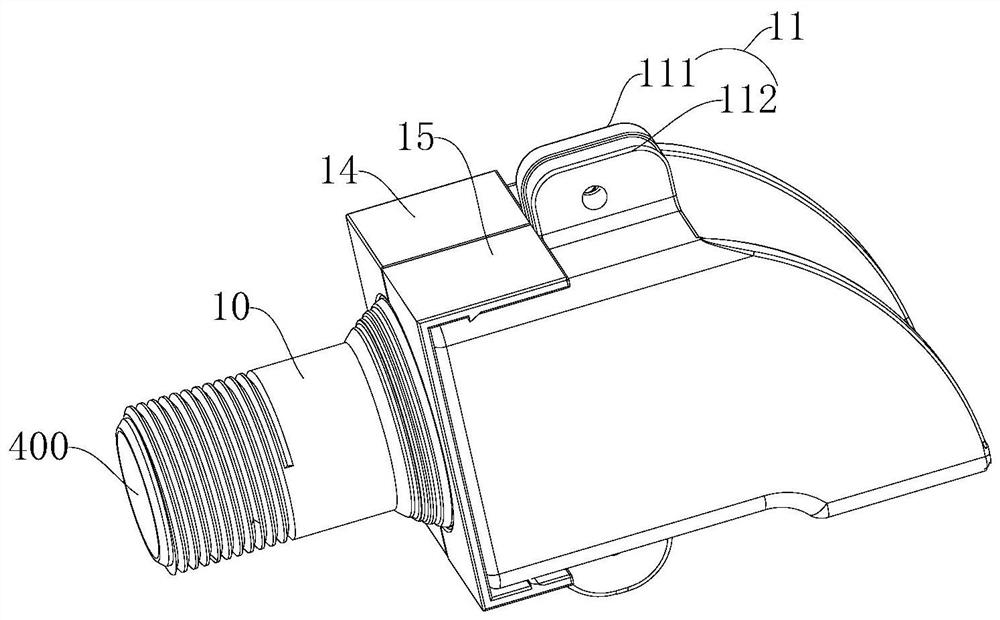

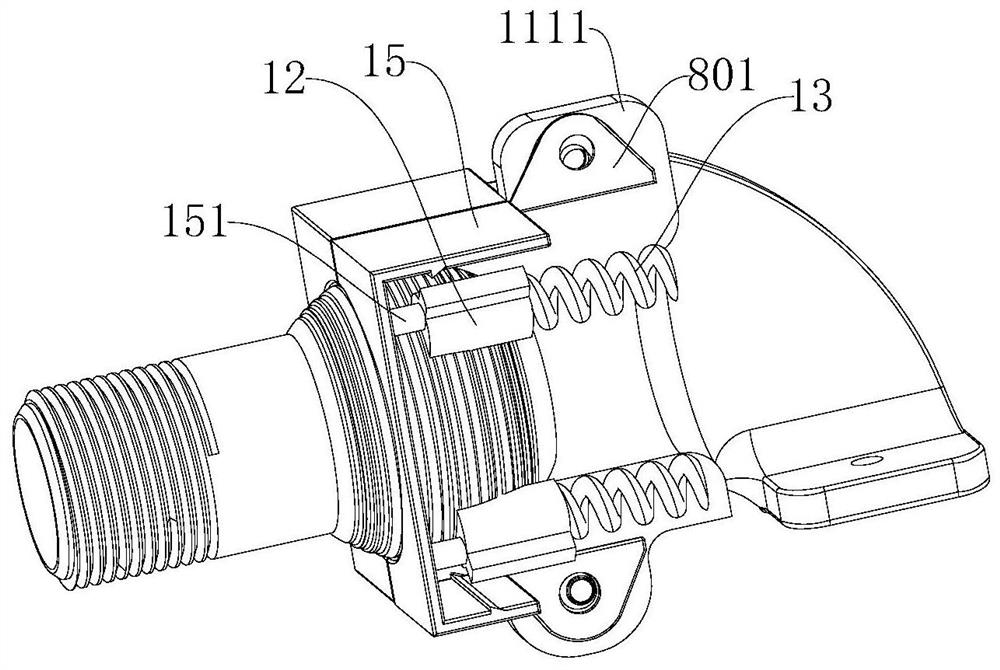

[0040] A component that automatically locks the rotating shaft, such as Figure 1-11 As shown, it includes a rotating shaft 10 and a fixed seat 11. The end of the fixed seat 11 is provided with a spherical cavity 110 along the axial direction. The rotating shaft 10 includes a spherical shaft head 101, and the shaft head 101 is installed in the cavity. 110 and axially locked on the fixed base 11 , the shaft head 101 can rotate in the cavity 110 , and the shaft head 101 rotates, so that the rotating shaft 10 rotates. The fixed seat 11 includes a first fixed seat 111 and a second fixed seat 112, the first fixed seat 111 and the second fixed seat 112 are assembled to form a cavity 110, that is, the first fixed seat 111 is provided with a half cavity, and the second fixed seat 111 The seat 112 is also provided with a half cavity, the half cavity on the first fixed seat 111 is combined with the half cavity on the second fixed seat 112 to form the cavity 110, the first fixed seat 111...

Embodiment 2

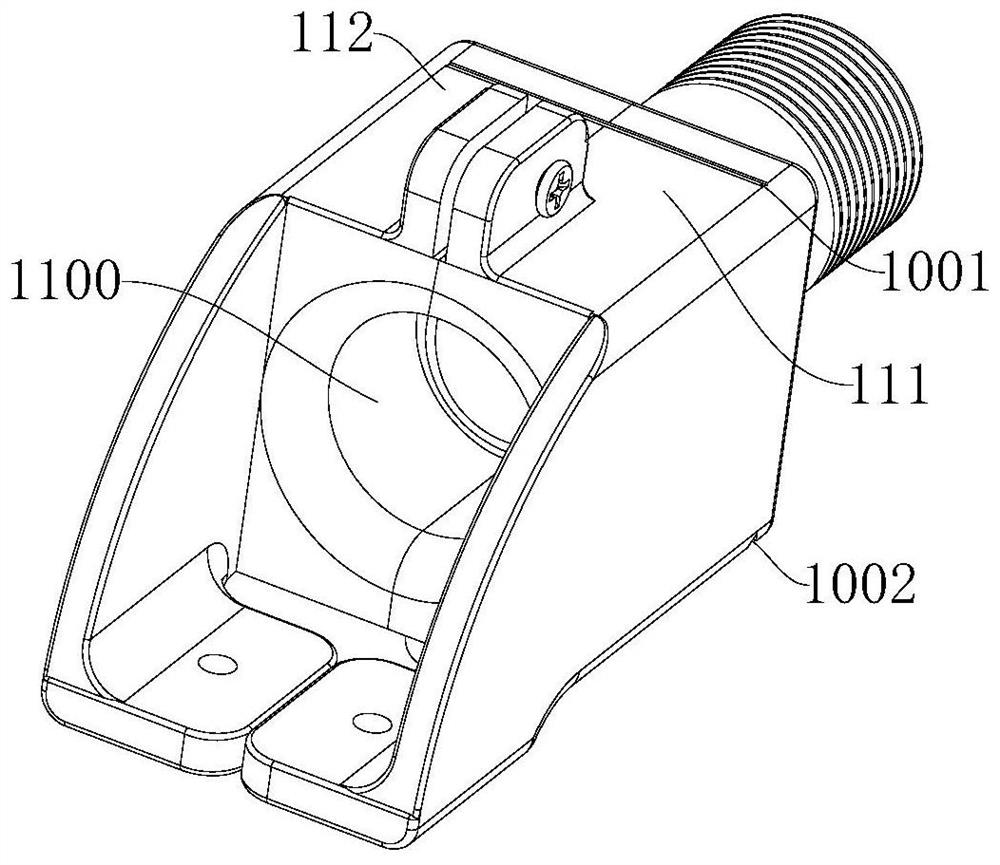

[0049] Embodiment 2 has basically the same features as Embodiment 1, except that the first fixing base 111 and the second fixing base 112 are respectively provided with a first through groove 1114 and a second through groove 1124, and the first through groove 1114 and the second through groove The grooves 1124 are all arc grooves. When the first fixed seat 111 and the second fixed seat 112 are fixed, the first through groove 1114 and the second through groove 1124 are synthesized into a channel 1100 communicating with the cavity 110, and the channel 1100 is cylindrical. The other end of 1100 passes through the fixing seat 11 . Lines such as signal lines or power lines are connected to other devices through the channel 1100 .

Embodiment 3

[0051] Embodiment 3 has basically the same features as Embodiment 1. The difference is that a first connecting plate 1115 extends from the side of the first fixing seat 111 away from the cavity 110, and the lower end of the first connecting plate 1115 is bent vertically inward to form a first fixing plate. plate 1116, the first fixed plate 1116 is provided with threaded holes connected with external equipment; the second fixed seat 112 extends away from the side of the cavity 110 with a second connecting plate 1125, and the lower end of the second connecting plate 1125 is folded vertically inward The second fixing plate 1126 is formed by bending, and the second fixing plate 1126 is provided with threaded holes for connecting with external equipment. Both the first connecting plate 1115 and the second connecting plate 1126 are arc-shaped connecting plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com