Mining machine cutting arm

A technology of mining machine and cutting arm, which is applied in the field of mining machine cutting arm and ore rock working face, can solve the problems of affecting mining, insufficient undercutting and lifting amount, etc., so as to achieve flexible structure layout and improve charging effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

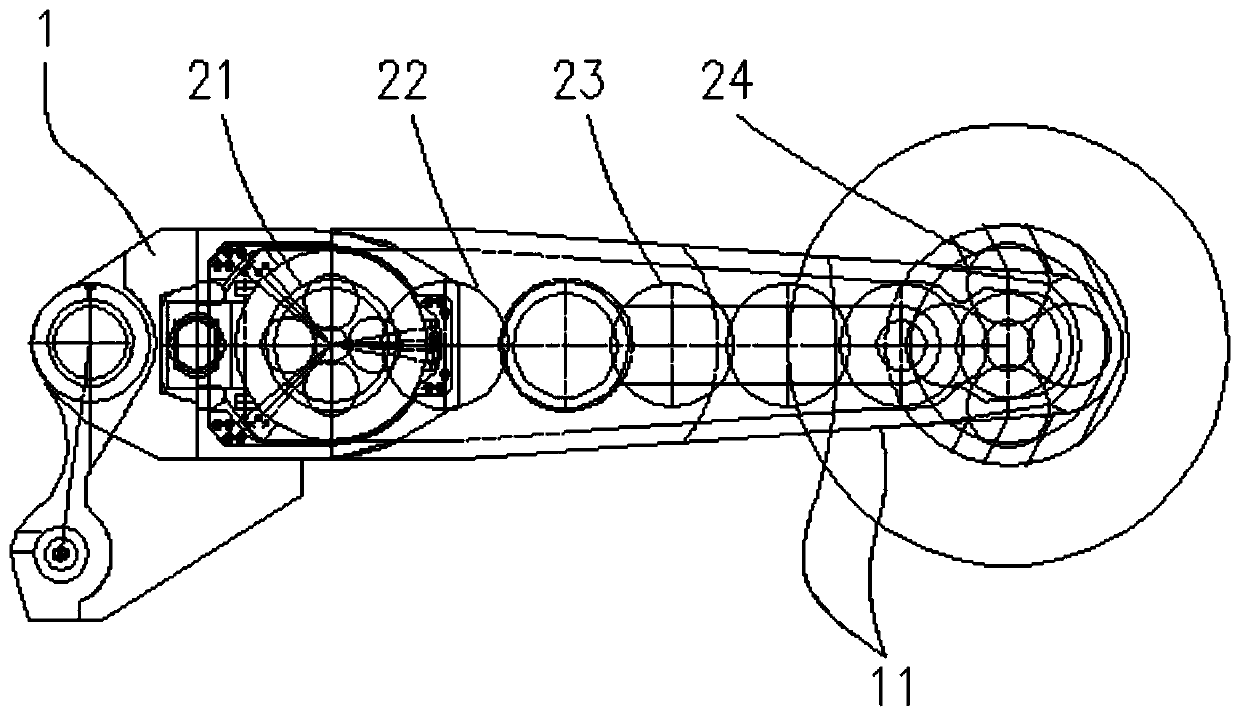

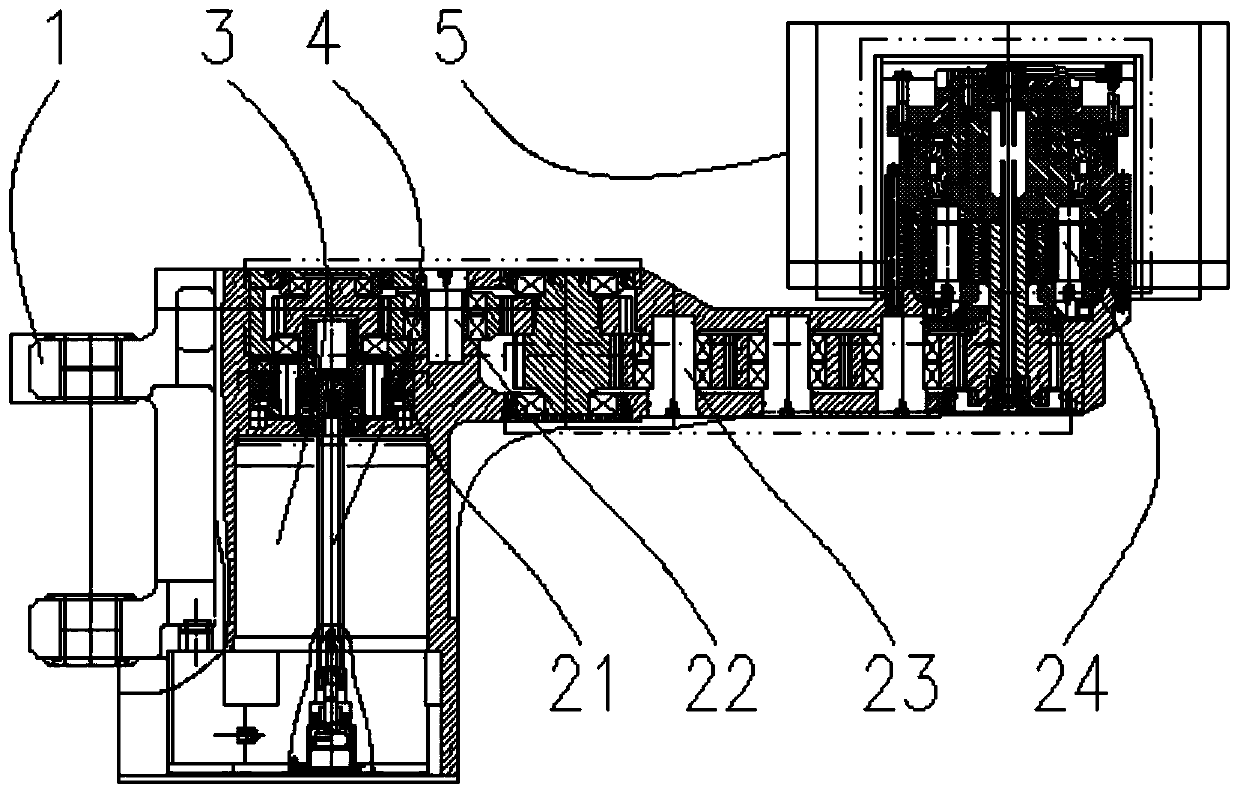

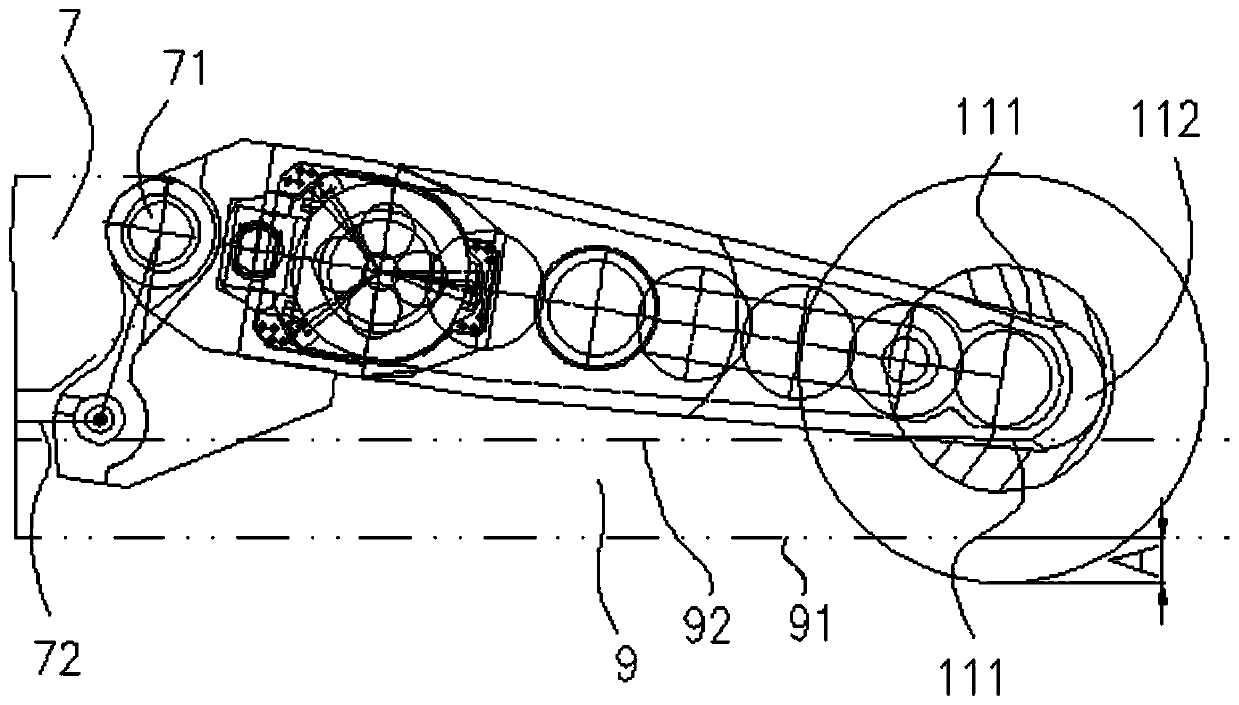

[0041] The invention discloses a mining machine cutting arm, such as Figure 1-12As shown, it includes a boom 1, a cutting motor 3, a transmission system, a clutch mechanism 4 and a small-diameter drum 5. The boom 1 is connected to the mining machine body 7 through a cutting arm connector 71 and a cutting arm cylinder 72 . In this paper, each part of the boom is named according to the distance from the fuselage when the boom is installed on the mining machine body 7 . The proximal end of the boom is provided with an installation interface structure for connecting with the mining machine body, such as connecting ear sockets. The distal end of the boom extends away from the fuselage. The arm frame includes a straight arm part, a motor mounting part protruding rearward from the proximal end of the straight arm part, and a roller mounting part protruding forward from the far end of the straight arm part. The cutting motor, transmission system and clutch mechanism are all arrang...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap