Grafted quaternary ammonium cation resin and preparation method thereof

A cationic resin and quaternary ammonium-based technology is applied in the field of grafted quaternary ammonium-based cationic resin and its preparation, which can solve the problems of poor electrical regeneration effect of strong acid and strong alkali mixed resin, and achieve the effect of improving electrical regeneration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

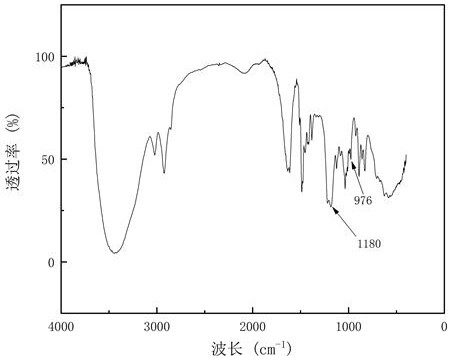

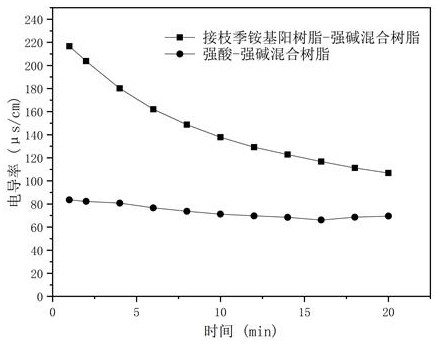

Method used

Image

Examples

Embodiment 1

[0038] 1) Introduction of quaternary ammonium groups in chloromethylated cross-linked polystyrene resin

[0039] 1.1) Add 15 parts of chloromethylated cross-linked polystyrene resin and 18 parts of trimethylamine hydrochloride to the reaction vessel in sequence;

[0040] 1.2) Add 72 parts of 20% sodium hydroxide aqueous solution dropwise to the reaction vessel within 1 hour, keep the reaction temperature at 30~40°C, and react for 2 hours under continuous stirring;

[0041] 1.3) After the reaction is completed, the reaction solution is filtered, transformed with 750 parts of 5% aqueous sodium hydroxide solution and 750 parts of 5% aqueous hydrochloric acid solution, and washed with 4500 parts of deionized water until the pH of the effluent is 7;

[0042] 1.4) drying at 60°C to obtain a chloromethylated cross-linked polystyrene resin with quaternary ammonium groups;

[0043] 2) Sulfonation of chloromethylated cross-linked polystyrene resins with quaternary ammonium groups

[0...

Embodiment 2

[0054] 1) Introduction of quaternary ammonium groups in chloromethylated cross-linked polystyrene resin

[0055] 1.1) Add 20 parts of chloromethylated cross-linked polystyrene resin and 20 parts of trimethylamine hydrochloride to the reaction vessel in sequence;

[0056] 1.2) Add 80 parts of 20% sodium hydroxide aqueous solution dropwise to the reaction vessel within 1 hour, keep the reaction temperature at 30~40°C, and react for 2 hours under continuous stirring;

[0057] 1.3) After the reaction is completed, the reaction solution is filtered, transformed with 1000 parts of 5% aqueous sodium hydroxide solution and 1000 parts of 5% hydrochloric acid aqueous solution, and washed with 6000 parts of deionized water until the pH of the effluent is 7;

[0058] 1.4) drying at 60°C to obtain a chloromethylated cross-linked polystyrene resin with quaternary ammonium groups;

[0059] 2) Sulfonation of chloromethylated cross-linked polystyrene resins with quaternary ammonium groups

...

Embodiment 3

[0070] 1) Introduction of quaternary ammonium groups in chloromethylated cross-linked polystyrene resin

[0071]1.1) Add 10 parts of chloromethylated cross-linked polystyrene resin and 5 parts of trimethylamine hydrochloride to the reaction vessel in sequence;

[0072] 1.2) Add 20 parts of 20% sodium hydroxide aqueous solution dropwise to the reaction vessel within 1 hour, keep the reaction temperature at 30~40°C, and react for 2 hours under continuous stirring;

[0073] 1.3) After the reaction is completed, the reaction solution is filtered, transformed with 500 parts of 5% aqueous sodium hydroxide solution and 500 parts of 5% aqueous hydrochloric acid solution, and washed with 3000 parts of deionized water until the pH of the effluent is 7;

[0074] 1.4) drying at 60°C to obtain a chloromethylated cross-linked polystyrene resin with quaternary ammonium groups;

[0075] 2) Sulfonation of chloromethylated cross-linked polystyrene resins with quaternary ammonium groups

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com