Water wall assembly adjusting bench and method

A water-cooled wall and bench technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low construction efficiency, achieve a good assembly work environment, improve on-site construction efficiency and tooling environment, and facilitate Effect of group pair welding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

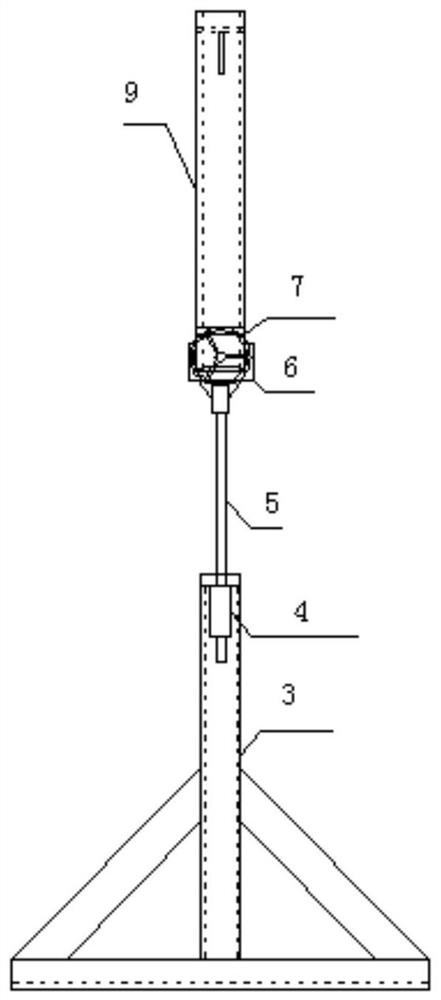

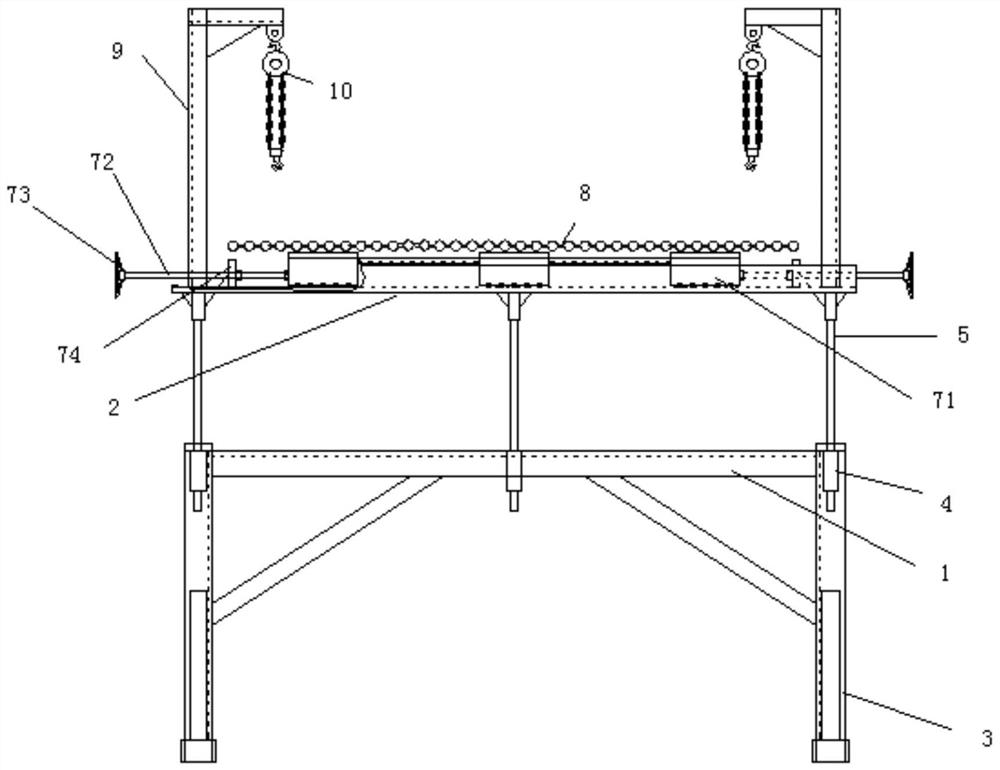

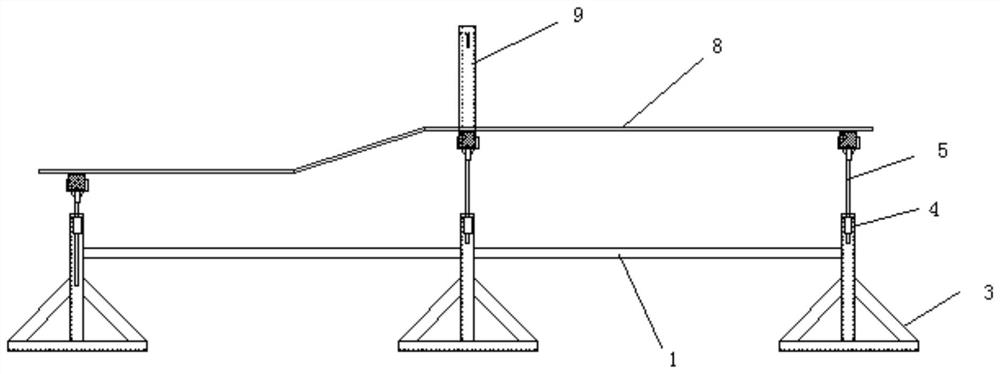

[0047] Such as Figure 1-10 As shown, the present invention provides a water-cooled wall assembly and adjustment platform, including:

[0048] There are at least six base units, and every two opposite base units are connected by corresponding first beams 1 to form a Figure 5 mast shown;

[0049] Here, according to the length of the water-cooled wall, several door frames can be set up to support it horizontally;

[0050] At least six telescopic support units, the lower part of a telescopic support unit is telescopically connected to a corresponding base unit, and every two opposite telescopic support units are connected through the corresponding second beam 2;

[0051] The second beam can be a channel steel beam, and the channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com