Welding robot and welding process for welding packing auger blades

A welding robot and auger blade technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of long spiral welding seam welding distance and poor welding effect consistency, and achieve strong welding efficiency and consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

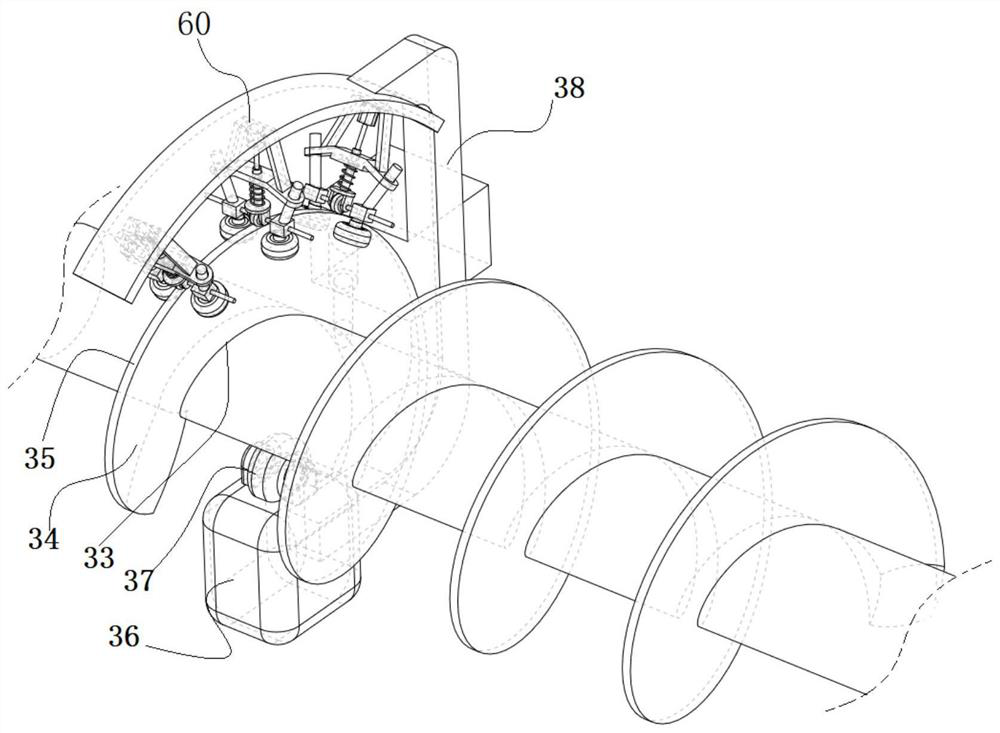

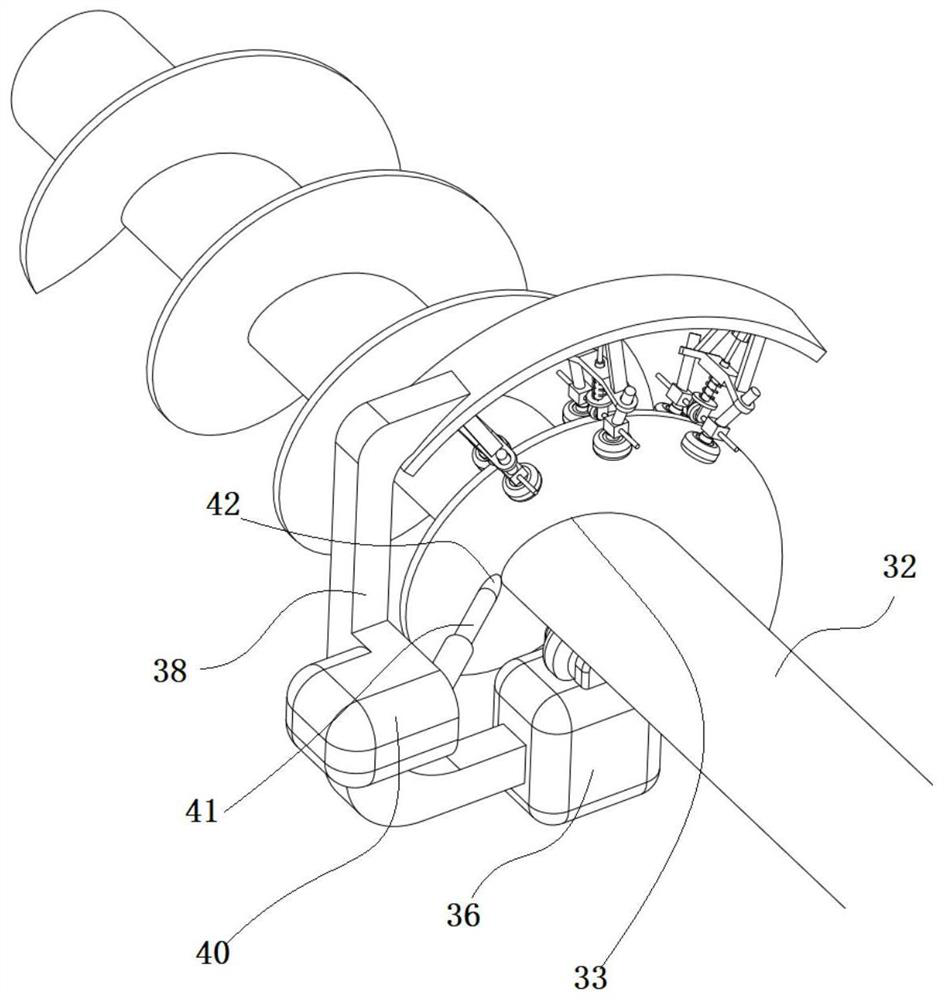

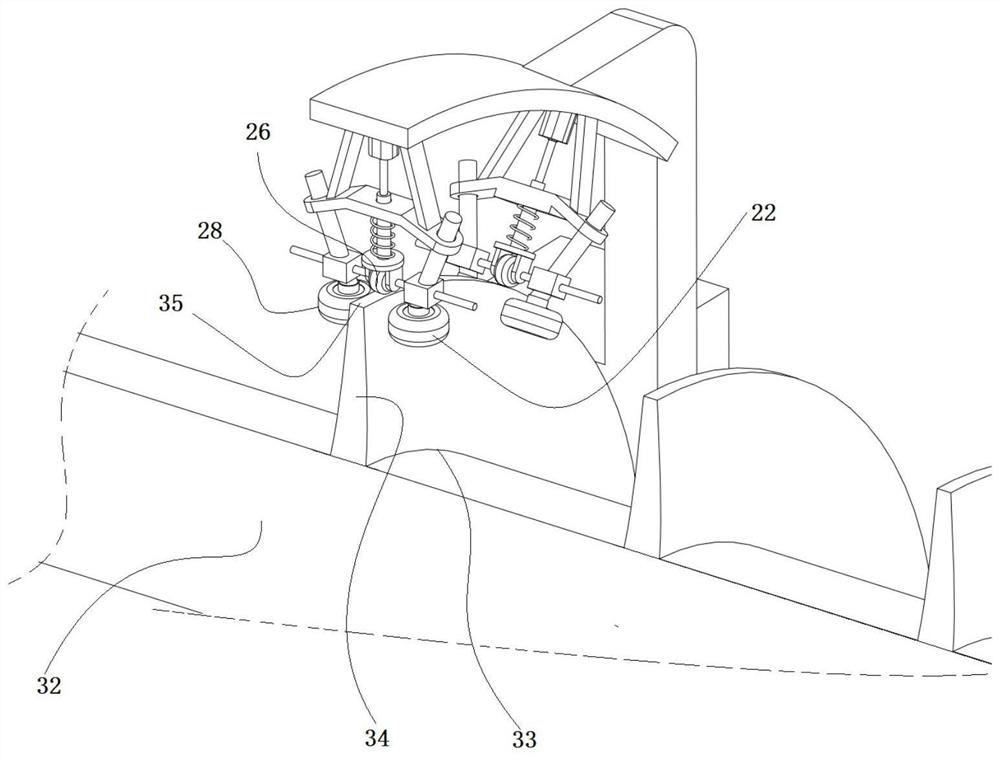

[0035] as attached Figures 1 to 9 The shown welding robot for welding the auger blades includes the helical auger blades 34 which are coaxially sleeved on the outside of the horizontally fixed auger blade shaft 32, and the helical inner edge root of the helical auger blades 34 is formed to wait for welding. Helical weld 33;

[0036] Also includes a welding robot, the welding robot can continuously weld the spiral weld 33, the welding robot includes a support unit, a walking power unit 101, a walking path constraint unit 100 and a welding unit; the walking power unit, the walking path constraint unit and the welding unit are all fixed Mounted on the stand unit.

[0037] The bracket unit includes a U-shaped frame 38, the welding unit is installed in the middle of the U-shaped frame 38, and the walking power unit 101 and the walking path constraint unit 100 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com